What is a circuit board resin plug hole? Why use resin plug hole

by:Rocket PCB

2020-07-09

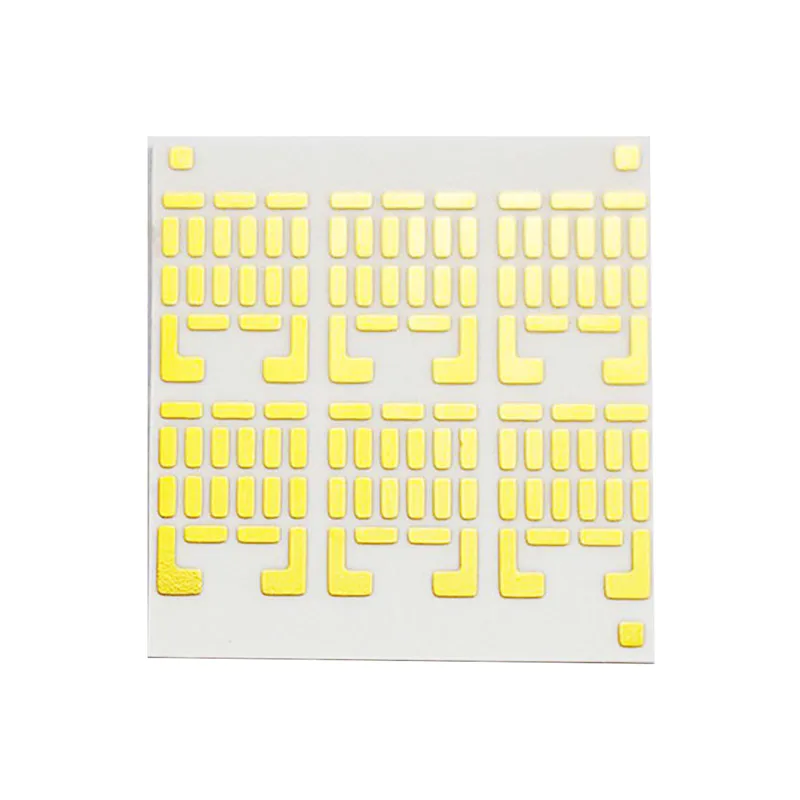

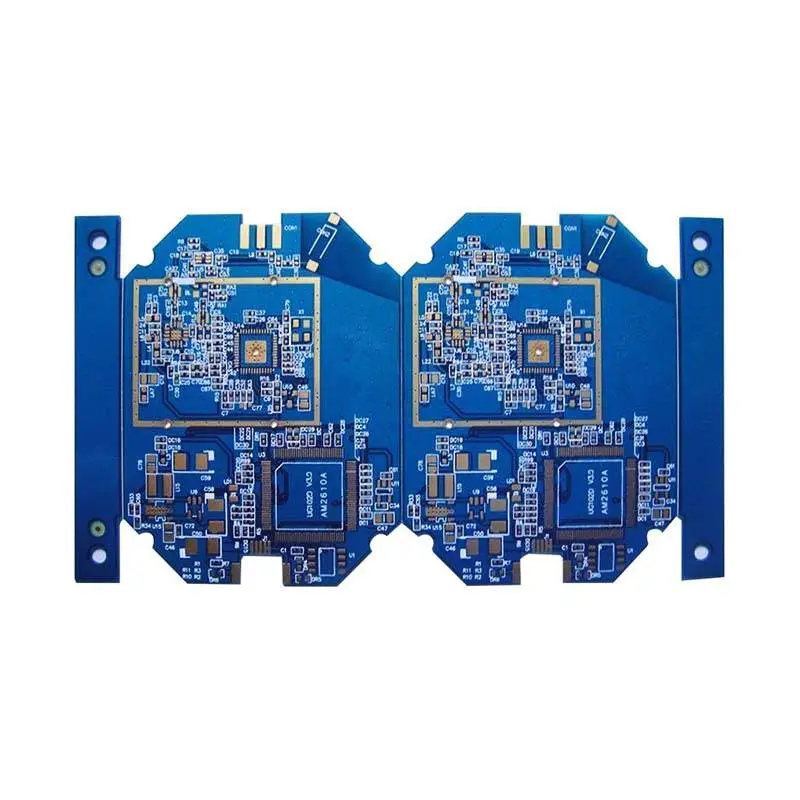

Circuit board using resin plug hole this process often because BGA parts, because traditional BGA might do VIA between PAD and PAD to go back to the line, but if BGA too close cause VIA can't walk out, you can directly from the PAD do VIA drilling into don't go to walk the line, then the hole filled with resin plating copper to PAD, which is commonly known as VIP process (

viainpad)

, if only via on PAD and not resin plug hole, is likely to cause leakage tin lead to short circuit on the back and front empty welding.

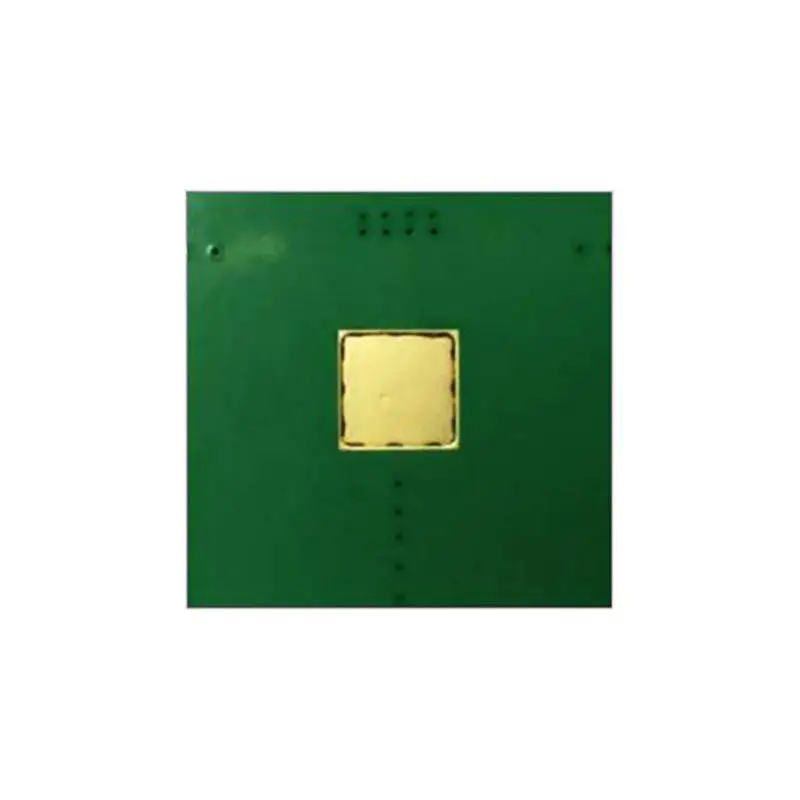

Circuit board resin plug hole process including drilling, plating, jack, roasting, grinding, drilling will be plated through hole, after baking, then plug resin is finally grinding grinding of flat and smooth after the resin because do not contain copper, so need to up a layer of copper will again it becomes PAD, these processes are done in the original PCB circuit board drilling system before, is the first fort hole hole processing good, then other holes, according to normal process.

Circuit board Kong Re didn't seal good, hole inside the bubble, because bubbles easily moisture absorption, circuit board PCB circuit board could explode when another tin stove plate, but if in the process of the plug hole hole inside the bubble, bubble will be when baking resin extrusion, cause side highlights the concave side of the situation, at that point can be bad for detection, and the circuit board that has bubble that would burst, because blasting plate is a major cause of moisture, so if it is just the factory of the board or the board on a toasted, generally don't cause explosion plate.

Rocket PCB Solution Ltd. guarantees to providing quality products and services.

Rocket PCB Solution Ltd. also values the time, skills, and expert opinions of our staff. We are committed to providing fair and living wages, reasonable, structured work schedules, and clear duties and spheres of rights and responsibilities for each team member.

With so many suggestions and tips on diferent solutions to pcb manufacturing services issues, it is truly important to know how to find the most appropriate pcb making service at economical price.

pcb manufacturing services pcb making service are primarily used for pcb manufacturing services.

Rocket PCB Solution Ltd. knew if this worked for us, it would work for others, so we took the exclusive product and program and re-developed it to be more accessible to customers.

Rocket PCB Solution Ltd. guarantees to providing quality products and services.

Rocket PCB Solution Ltd. also values the time, skills, and expert opinions of our staff. We are committed to providing fair and living wages, reasonable, structured work schedules, and clear duties and spheres of rights and responsibilities for each team member.

With so many suggestions and tips on diferent solutions to pcb manufacturing services issues, it is truly important to know how to find the most appropriate pcb making service at economical price.

pcb manufacturing services pcb making service are primarily used for pcb manufacturing services.

Rocket PCB Solution Ltd. knew if this worked for us, it would work for others, so we took the exclusive product and program and re-developed it to be more accessible to customers.

Custom message