systems: manufacturing techniques

by:Rocket PCB

2019-11-14

Industrial production technology using computer-aided design (CAD)

Computer-aided manufacturing (CAM)

In a manufacturing environment, there are four terms used to describe the scale of production associated with the manufacturing product: prototype or one-

Batch production continuous production prototype and 1-

Available for testing and user testing.

In addition to this, you can also use one-customize professional machines and vehicles for customersoff production.

Professional workers and production aids are required.

This can produce high

Quality and original items, but it is usually expensive to make and buy them, and it takes highly skilled workers to produce them.

When testing a circuit, you can use a breadboard or a stripping board to ensure that the circuit works properly without more permanent welding.

If the circuit works after the prototype test, then it is possible to manufacture the circuit in large quantities.

Mass production is the production of many items of the same product, such as mobile phones and TV.

A range of products can be produced, especially those that are replaced on a regular basis, but time is wasted when there is a need for re-processing and skilled workers.

When a product is produced in bulk, each product is usually much cheaper than producing only one product.

Mass production

The products produced are manufactured in large quantities and are usually manufactured by automated machinery, and workers on assembly lines are used to assemble parts together or to add standard components, such as switches.

Examples of mass production of electronic and mechanical systems include radios, remote controls, and cars.

The bulk materials and components are cheaper due to heavy manufacturing, and the products remain low cost.

However, it will cost a lot to build such an assembly line.

Continuous production is 24 hours a day, 7 days a week, 365 days a year in some cases.

It can produce a large number of products such as circuit boards or lamps at low cost

LEDs (LEDs)

However, it is limited to small-scale products, and as with mass production, it is very expensive to install. Just in time (JIT)Just in time (JIT)

Manufacturing is triggered by customer orders.

The correct quantity of materials was ordered to pay for the order, which is exactly what is needed for production.

This saves storage costs, reduces waste, and ensures that production inventory does not waste any unsold funds.

The disadvantage of the system is that if any part of the product cannot be purchased, the customer must wait for the production of the order.

Use the fixture in production to help the precise production of parts and products, make the fixture.

It can be very time when many components need the same manufacturing --

No fixture consumption.

Fixtures can: protect components when accurately machining or assembling them, ensure that all components are the same as before, and reduce human errors in computer-aided designs (CAD)

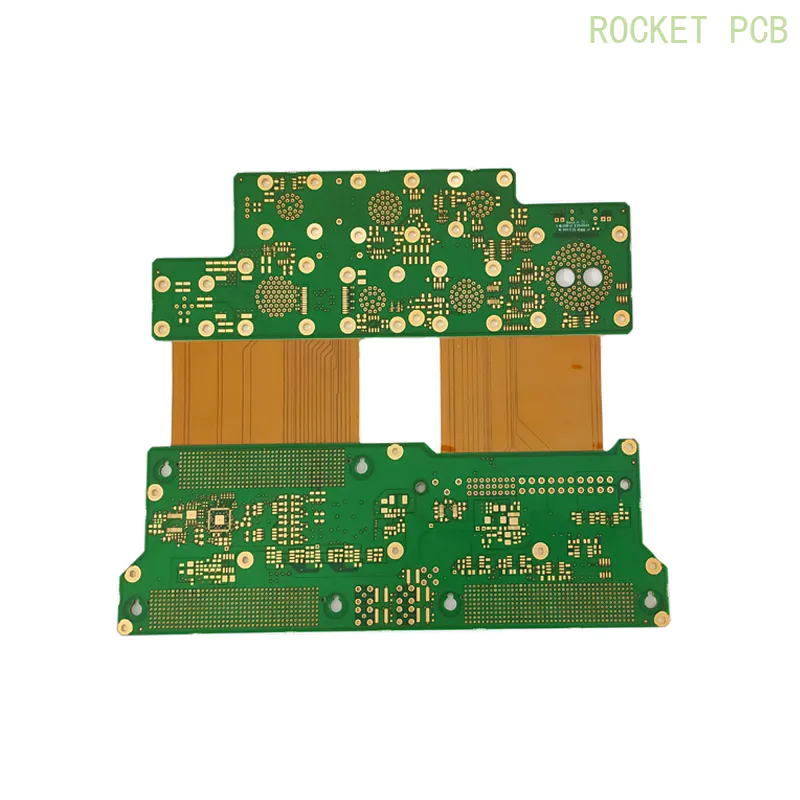

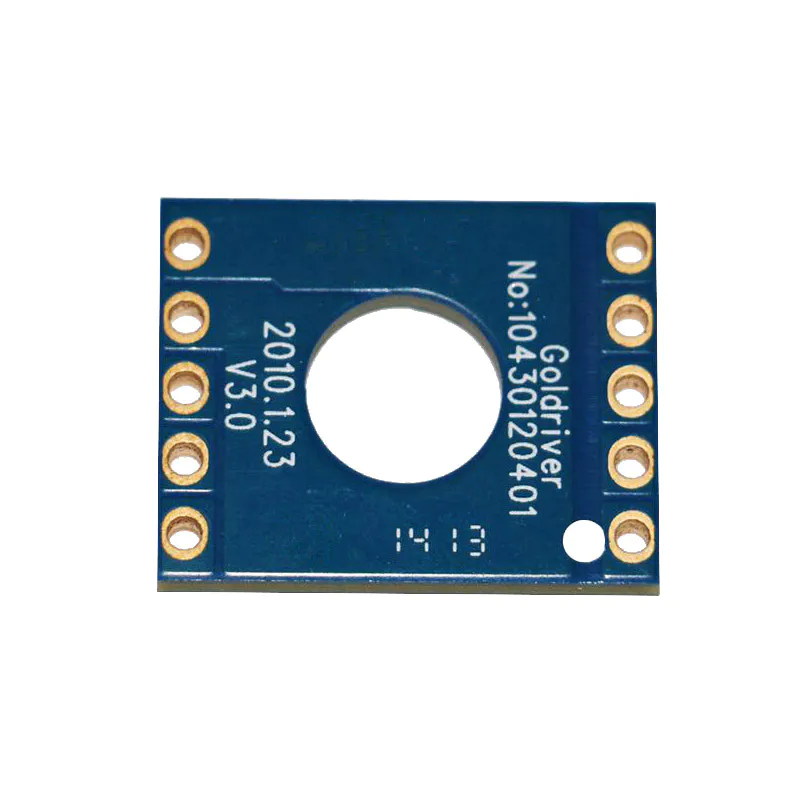

Increase the complexity of electronic products: printed circuit boards (PCBs)

The microprocessor can be produced to the smallest scale. The designed circuit board simulation can be digitally tested before manufacturing begins. It saves time and can test the input and output of money through CAD software. Replaces the need to test physical models of electronic systems in computer-aided manufacturing (CAM)

Use advanced mechanical equipment to read information from CAD software files.

The CAM machine can then perform different automation functions accurately from the data, such as: drilling computer numerical control (CNC)

Computer-aided manufacturing (CAM)

In a manufacturing environment, there are four terms used to describe the scale of production associated with the manufacturing product: prototype or one-

Batch production continuous production prototype and 1-

Available for testing and user testing.

In addition to this, you can also use one-customize professional machines and vehicles for customersoff production.

Professional workers and production aids are required.

This can produce high

Quality and original items, but it is usually expensive to make and buy them, and it takes highly skilled workers to produce them.

When testing a circuit, you can use a breadboard or a stripping board to ensure that the circuit works properly without more permanent welding.

If the circuit works after the prototype test, then it is possible to manufacture the circuit in large quantities.

Mass production is the production of many items of the same product, such as mobile phones and TV.

A range of products can be produced, especially those that are replaced on a regular basis, but time is wasted when there is a need for re-processing and skilled workers.

When a product is produced in bulk, each product is usually much cheaper than producing only one product.

Mass production

The products produced are manufactured in large quantities and are usually manufactured by automated machinery, and workers on assembly lines are used to assemble parts together or to add standard components, such as switches.

Examples of mass production of electronic and mechanical systems include radios, remote controls, and cars.

The bulk materials and components are cheaper due to heavy manufacturing, and the products remain low cost.

However, it will cost a lot to build such an assembly line.

Continuous production is 24 hours a day, 7 days a week, 365 days a year in some cases.

It can produce a large number of products such as circuit boards or lamps at low cost

LEDs (LEDs)

However, it is limited to small-scale products, and as with mass production, it is very expensive to install. Just in time (JIT)Just in time (JIT)

Manufacturing is triggered by customer orders.

The correct quantity of materials was ordered to pay for the order, which is exactly what is needed for production.

This saves storage costs, reduces waste, and ensures that production inventory does not waste any unsold funds.

The disadvantage of the system is that if any part of the product cannot be purchased, the customer must wait for the production of the order.

Use the fixture in production to help the precise production of parts and products, make the fixture.

It can be very time when many components need the same manufacturing --

No fixture consumption.

Fixtures can: protect components when accurately machining or assembling them, ensure that all components are the same as before, and reduce human errors in computer-aided designs (CAD)

Increase the complexity of electronic products: printed circuit boards (PCBs)

The microprocessor can be produced to the smallest scale. The designed circuit board simulation can be digitally tested before manufacturing begins. It saves time and can test the input and output of money through CAD software. Replaces the need to test physical models of electronic systems in computer-aided manufacturing (CAM)

Use advanced mechanical equipment to read information from CAD software files.

The CAM machine can then perform different automation functions accurately from the data, such as: drilling computer numerical control (CNC)

Custom message