Structure and Manufacturing Difficulties of Aluminum PCB

What is Aluminum PCB?

An aluminum PCB has a similar layout to any other PCB. It has a layer or layers of copper, solder mask and silkscreen layered over it. Instead of having a fiberglass or plastic substrate, though, an aluminum circuit board has a metal substrate. This base mainly contains a combination of aluminum. The metal core can consist entirely of metal or have a combination of fiberglass and aluminum. Aluminum PCBs typically are single sided, but can be double sided as well. Mulilayer Aluminum PCBs are highly difficult to manufacture.

Aluminum boards get the most use in LED and power converting electronics. The intense light produced by LEDs creates high levels of heat, which aluminum directs away from components. An aluminum PCB extends the lifespan of an LED device and provides more stability. You can find aluminum substrates in street lights, stop lights and household lighting. They allow power converters to change currents and regulate electronics. Creators in many other industries also find use in aluminum circuit boards, but they don't implement them as often.

Why is Aluminium Used in Print Circuit Boards?

Aluminum can actually transfer heat away from vital components, thus minimizing the harmful effect it could have on the circuit board. Higher durability: Aluminum provides strength and durability to a product that ceramic or fiberglass bases cannot.

Structure of Aluminum PCB

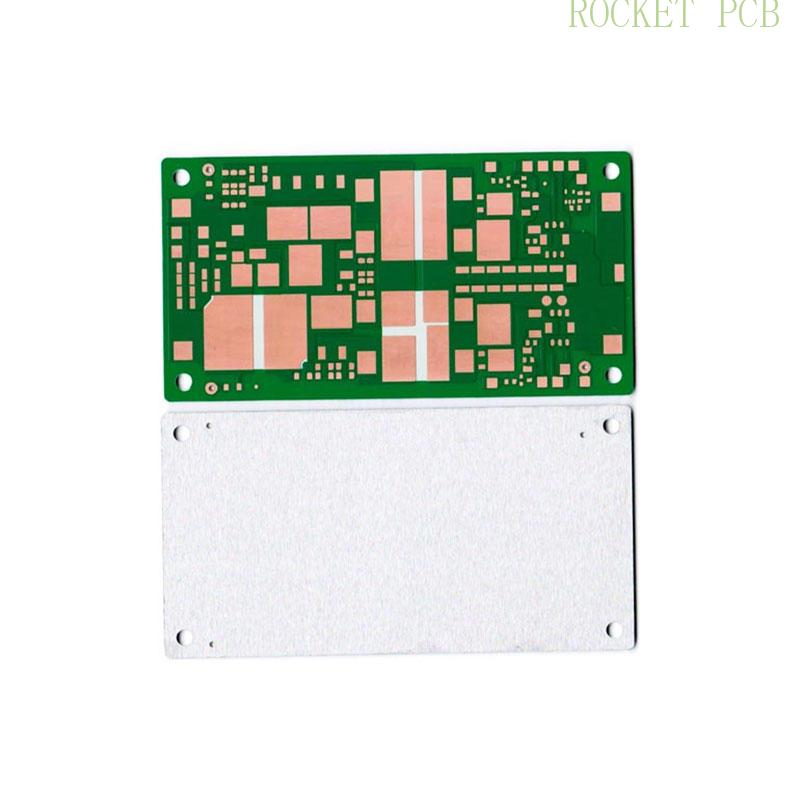

Aluminum PCBs are aluminum based CCLs (CCL is a type of base material of PCBs). AluminumPCBs are actually quite similar to FR4 PCBs. The basic structure of Aluminum PCBs is four layered. It consists of a layer of copper foil, a dielectric layer, an aluminum base layer and aluminum base membrane.

Copper Foil Layer: the copper layer used is relatively thicker than normal CCLs ( 1oz-10oz). A thicker layer of copper means a larger current carrying capacity.

Dielectric Layer: the Dielectric layer is a thermally conductive layer and is around 50μm to 200μm thick. It had a low thermal resistance and it suitable for its application.

Aluminum Base: The third layer isthe aluminum base which is made up of aluminum substrate. It has a high thermal conductivity.

Aluminum Base Membrane Layer: Aluminum base membrane is selective. It has a protective role by keeping the aluminum surface safe from scraping and unwanted etching. It is of two types i.e. Lower than 120 degree or around 250 degrees (anti high temperature).

Classification of Aluminum PCB

High quality aluminum PCBs are essentially divided into three categories.

Universal Aluminum PCB: the dielectric layer used here is made up of epoxy glass fiber pre-preg.

High Thermal-Conductive Aluminum PCB: the dielectric layer is made up of epoxy resin. The resin used must have high thermal conductivity.

High-frequency Aluminum PCB: the dielectric layer is composed of polyolefin or polyimide resin glass fiber pre-preg.

Manufacturing Difficulties of Aluminum PCB

The manufacturing process for nearly all aluminum PCBs is essentially the same. Here we will discuss the major manufacturing processes, the difficulties and their solutions.

Copper Etching: the copper foil used in Aluminum PCBs is comparatively thicker. If the copper foil is over 3oz however, the etching requires width compensation. If it is not according to the demand of the design, the trace width will be out of tolerance after etching. Therefore the trace width compensation should be designed accurately. The etching factors need to be controlled during manufacturing process.

Solder Mask Printing: due to the thick copper foil there is a difficulty in solder mask printing of aluminum PCB board. This is because if the trace copper is too thick then the image etched will have a large difference between trace surface and base board and solder mask printing will be difficult. Therefore, the two-time solder mask printing is used. The solder mask oil used should be of good quality and in some cases the resin filling is done first and then solder mask.

Mechanical Manufacturing: the mechanical manufacturing process involves mechanical drilling, molding and v-scoring etc. which Is left on internal via. This tends to reduce electrical strength. Therefore, the electric milling and professional milling cutter should be utilized for low-volume manufacturing of products. The drilling parameters should be adjusted to prevent burr from generating. This will help your mechanical manufacturing.

Rocket PCB: An Experienced Aluminum PCB Manufacturer

Rocket PCB, one of the largest and most popular PCB manufacturers in China. Rocket PCB specializes in manufacturing high-quality PCBs (Printed Circuit Boards) in low price. These boards are custom designed according to your needs. Our full feature aluminum circuit boards making capabilities allows you to get high-quality aluminum PCBs done within budget. Our printed Aluminum PCBs are widely used for LED lighting, power equipment and automotive systems.