\"sierra proto express presents tomorrow\'s technology-today!\" tired of endless evolution? are you ready for a real revolution?

by:Rocket PCB

2019-12-16

In 2004, it was time for Sierra Proto Express to decide to be achange-

Now is the time for the US electronics industry to wake up from a deep sleep and re-emerge as the world\'s innovation leader in printed circuit boards.

It\'s time to look back.

It\'s time to raise expectations.

It\'s time to fundamentally rethink how PCBs are made.

Now is the time.

When others are processed due to old technical capabilities.

While others have a wait-and-see view of what new technologies are being adopted, we have taken a step forward.

While other PCB manufacturers are content to survive the downturn, we are reborn.

\"Once you turn this page, there is no way back.

High reliability board (Hi. Rel. )Our Hi. Rel.

The reliability of the printed circuit board is unparalleled, able to withstand more thermal cycles and higher temperatures than existing circuit boards.

This high reliability circuit uses proprietary plating technology to strengthen the copper in the hole and tolerate the expansion of the laminate during repeated thermal cycles. [

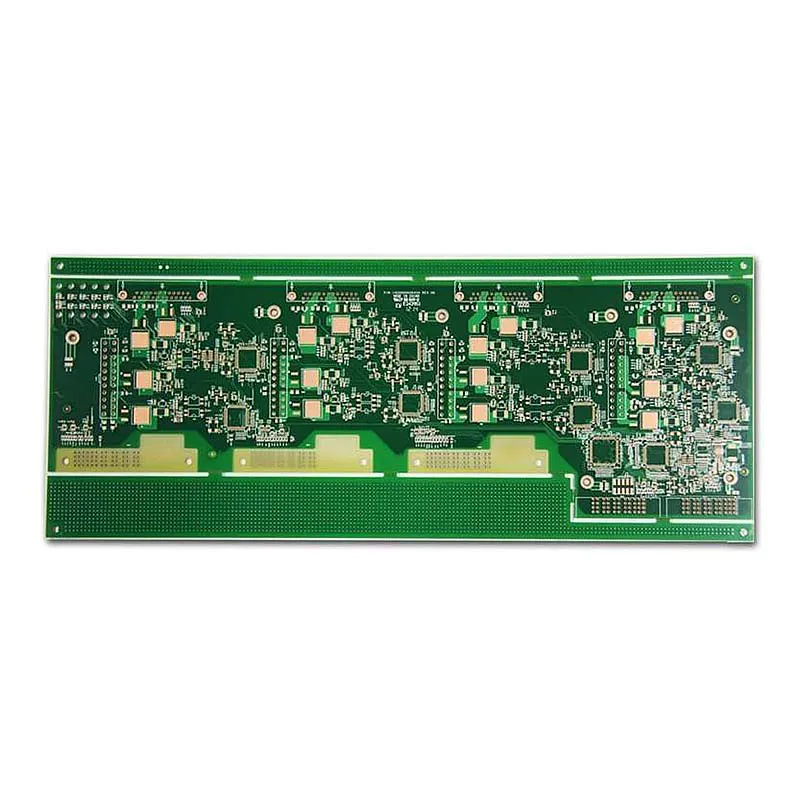

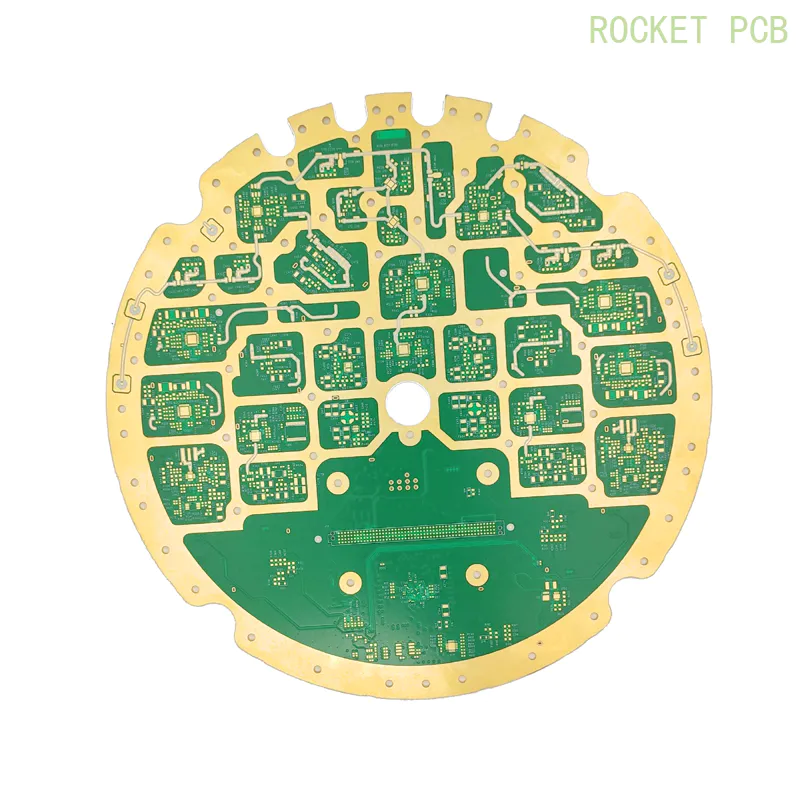

Slightly] Illustrations

This breakthrough in reliability significantly improves the service life of the product.

The cost of replacing and repairing damaged electronics used by cracked vias is amazing.

Your company no longer needs to experience these board failures.

If you make an application for medical, space, aviation, transportation or any product that cannot fail, you need advanced protection from Hi. E. R.

High reliability circuit.

For general multi-layer structure and copper plating, a4-to 6-layer 0.

The average results of the 062 \"board HATS test with Tg of 135 showed the average results.

But use the same low temperature 135 Tg FR4 laminate, hi. Rel.

The plate shows a significant increase in the number of cycles on the hat tester.

\"Fact: * over 2,000 thermal cycles-40 to 145[degrees]C.

* Can withstand 30 welding cycles at 570 [degrees]F (

Three times the new clue. free T288 test). [Graphics omitted]

* 135 [low T/Gdegrees]C FR-

Four samples survived 1,800 cycles, far exceeding the typical 120 cycles in the industry.

* Welding float test was started in Hi sample. E.

Repeated welding and soaking of Rboards. Hi. E. R. FR-4135[degrees]

C. Tg circuit has lived 30 cycles in 10 seconds [degrees]F.

High reliability lead

We have created a superior lead. free, high-

Temperature circuit board combined with our high reliability circuit board (Hi. E. R. )

Electroplating process with high TD leads-free laminate (

WEEE & rohsdirect-certified). Tests on FR-4 Hi. Rel.

After 350 [8 hours], the sample showed no viafailuredegrees]

Exceed the standard of materials.

A 30-minute solder tank test was conducted at 550 [degrees]

Although the laminate showed obvious damage, C showed no signs of cracking or passing through the fault. Hi. E.

R is ideal for leads

Free welding applications requiring a temperature/time rating greater than t288.

Quick Facts: * to verify our reliability statement, send samples of the mixed structure and control of the normal pcb to conductor Analytica (CAT)

The IRTS test service for a long time thermal cycling on the hat tester.

Samples are pre-processed on IRTS with ipc PCQ [R. sup. 2]

The assembly cycle standard for 6 simulated welding assembly cycles is then thermal tested.

After 13 days and 2,000 cycles, FR-4 six-

In the case of a resistance change of less than 2,000, the laminate passes through 2% cycles. * A lead-

In the sample of Hi, the free welding floating test was also started. E.

Repeated welding and soaking of the R plate. TheHi. E. R FR-4 lead-

Free laminate survived more than 30 cycles in at50 [10 seconds]degrees]F--

No evidence of any holes.

Compared to 5-industry standards

7 cycles, hi. E.

The PCB is proved to be a very strong circuit board.

Are you ready for the revolution?

\"Thin wire technology when PCB manufacturers make boards with 4/4--or even 3/3--

Line and space, inaccurate measurement.

The weakening of etching has distorted the shape of the track by 2-mils of cross-sectionalwidth.

By etching copper, it weakens base metal and plating

On copper, reduce the width of the line and create a fragment above that can break.

This fracture leads to shorts when reducing Cross

Segment thickness of line width.

Our thin line technology is different.

Instead of using destructive etching, it uses a new platform technology to create thin lines.

The thinner the line, and more importantly, the narrower the space, the more important the plating accuracy is.

Fast facts: * 4/4 lines and spaces can be etched into 1/2 ounces.

Copper wire width minimum.

* 4/4 outers are usually plated from 1/2 ounces.

Foil to the required 1 ounce. copper.

* Sierra Proto Express produces our heavy duty copper plates from 4 oz to 2 oz using its new plating technology. up to 15 oz.

Copper, available in singlesided, double-

Side or multiple layers.

With a current of up to 600 amps, engineers can now design a PCB that carries a large number of circuits and supports the fine track and functionality required by the computer board to drive high power.

We offer a range of different heavy duty copper technologies for engineers and designers who can handle tricky power, heat

Sinking project

With this technology, we can accurately plating copper to 4 ounces.

Thick, when combined with basestart copper.

Previously, PCB manufacturers would not even cite

More than 3 ounces of side plate design.

We will quote and produce your heavy copper design eagerly.

Quick fact: * our multi-level allows 8 ounces on the first floor.

Heavy track copper, 1 ounce. of fine-

Characteristic traces of SMT circuits, all of which are interrelated and intertwined. * A two-

The maximum current of the ounce circuit is about 25 amps; a1\"-wide 15 oz.

Trace can carry 200 amps in just 30 [degrees]C rise.

* Although the thickness of copper can vary by layer, the line/spacing is 3 miles per ounce.

Heavy copper can be asa-based copper of any thickness of 1/2 ounces. to 12 oz.

Compared to the final copper thickness, the thicker the base copper thickness, the less the plate and the cost.

Our cheap flexable flexible laminate is a limited alternative to flexible circuits and costs only a fraction of the cost. This FR-4-

The substrate thickness is from 0. 002\" (

Very flexible and flexible but limited robustness)to 0. 008 \"thickness (

No flex but stronger). Single-or double-

There are ED or RA foil on the side of this product.

This material can be used to replace the flex (i. e.

Not often bent)

The situation is not dynamic (

Repeated bending motion)state.

This product is for you if you are buying flex, using a harness, or asking the board to bend around the enclosure.

Quick fact: * double

Double sided products can pass through the hole-

Plated with copper thickness up to 12 ounces.

* Final finish available in gold, tin and tinlead.

A flexible welding mask is used.

* Flexable flex is a cheap alternative to flat cables and other lines (including high power busbars.

\"Join this revolution and open this page. . .

\"First of all, we ask our customers what they want to accomplish.

Then we dream, conceive, research, develop, test.

We have done what others think is impossible.

We are not satisfied with the development of printed circuits.

So we created the printing circuit revolution.

It\'s time.

Is the revolution ready? Call 1-800-763-7503, ext.

500 or visit www. protoexpress.

1108 West Evelyn Avenue

, Sunnyvale, CA 94086 Email: Archive @ protoexpress.

Visit us at PCB West 2005 (booth 1205)from March 7-11, 2005.

Now is the time for the US electronics industry to wake up from a deep sleep and re-emerge as the world\'s innovation leader in printed circuit boards.

It\'s time to look back.

It\'s time to raise expectations.

It\'s time to fundamentally rethink how PCBs are made.

Now is the time.

When others are processed due to old technical capabilities.

While others have a wait-and-see view of what new technologies are being adopted, we have taken a step forward.

While other PCB manufacturers are content to survive the downturn, we are reborn.

\"Once you turn this page, there is no way back.

High reliability board (Hi. Rel. )Our Hi. Rel.

The reliability of the printed circuit board is unparalleled, able to withstand more thermal cycles and higher temperatures than existing circuit boards.

This high reliability circuit uses proprietary plating technology to strengthen the copper in the hole and tolerate the expansion of the laminate during repeated thermal cycles. [

Slightly] Illustrations

This breakthrough in reliability significantly improves the service life of the product.

The cost of replacing and repairing damaged electronics used by cracked vias is amazing.

Your company no longer needs to experience these board failures.

If you make an application for medical, space, aviation, transportation or any product that cannot fail, you need advanced protection from Hi. E. R.

High reliability circuit.

For general multi-layer structure and copper plating, a4-to 6-layer 0.

The average results of the 062 \"board HATS test with Tg of 135 showed the average results.

But use the same low temperature 135 Tg FR4 laminate, hi. Rel.

The plate shows a significant increase in the number of cycles on the hat tester.

\"Fact: * over 2,000 thermal cycles-40 to 145[degrees]C.

* Can withstand 30 welding cycles at 570 [degrees]F (

Three times the new clue. free T288 test). [Graphics omitted]

* 135 [low T/Gdegrees]C FR-

Four samples survived 1,800 cycles, far exceeding the typical 120 cycles in the industry.

* Welding float test was started in Hi sample. E.

Repeated welding and soaking of Rboards. Hi. E. R. FR-4135[degrees]

C. Tg circuit has lived 30 cycles in 10 seconds [degrees]F.

High reliability lead

We have created a superior lead. free, high-

Temperature circuit board combined with our high reliability circuit board (Hi. E. R. )

Electroplating process with high TD leads-free laminate (

WEEE & rohsdirect-certified). Tests on FR-4 Hi. Rel.

After 350 [8 hours], the sample showed no viafailuredegrees]

Exceed the standard of materials.

A 30-minute solder tank test was conducted at 550 [degrees]

Although the laminate showed obvious damage, C showed no signs of cracking or passing through the fault. Hi. E.

R is ideal for leads

Free welding applications requiring a temperature/time rating greater than t288.

Quick Facts: * to verify our reliability statement, send samples of the mixed structure and control of the normal pcb to conductor Analytica (CAT)

The IRTS test service for a long time thermal cycling on the hat tester.

Samples are pre-processed on IRTS with ipc PCQ [R. sup. 2]

The assembly cycle standard for 6 simulated welding assembly cycles is then thermal tested.

After 13 days and 2,000 cycles, FR-4 six-

In the case of a resistance change of less than 2,000, the laminate passes through 2% cycles. * A lead-

In the sample of Hi, the free welding floating test was also started. E.

Repeated welding and soaking of the R plate. TheHi. E. R FR-4 lead-

Free laminate survived more than 30 cycles in at50 [10 seconds]degrees]F--

No evidence of any holes.

Compared to 5-industry standards

7 cycles, hi. E.

The PCB is proved to be a very strong circuit board.

Are you ready for the revolution?

\"Thin wire technology when PCB manufacturers make boards with 4/4--or even 3/3--

Line and space, inaccurate measurement.

The weakening of etching has distorted the shape of the track by 2-mils of cross-sectionalwidth.

By etching copper, it weakens base metal and plating

On copper, reduce the width of the line and create a fragment above that can break.

This fracture leads to shorts when reducing Cross

Segment thickness of line width.

Our thin line technology is different.

Instead of using destructive etching, it uses a new platform technology to create thin lines.

The thinner the line, and more importantly, the narrower the space, the more important the plating accuracy is.

Fast facts: * 4/4 lines and spaces can be etched into 1/2 ounces.

Copper wire width minimum.

* 4/4 outers are usually plated from 1/2 ounces.

Foil to the required 1 ounce. copper.

* Sierra Proto Express produces our heavy duty copper plates from 4 oz to 2 oz using its new plating technology. up to 15 oz.

Copper, available in singlesided, double-

Side or multiple layers.

With a current of up to 600 amps, engineers can now design a PCB that carries a large number of circuits and supports the fine track and functionality required by the computer board to drive high power.

We offer a range of different heavy duty copper technologies for engineers and designers who can handle tricky power, heat

Sinking project

With this technology, we can accurately plating copper to 4 ounces.

Thick, when combined with basestart copper.

Previously, PCB manufacturers would not even cite

More than 3 ounces of side plate design.

We will quote and produce your heavy copper design eagerly.

Quick fact: * our multi-level allows 8 ounces on the first floor.

Heavy track copper, 1 ounce. of fine-

Characteristic traces of SMT circuits, all of which are interrelated and intertwined. * A two-

The maximum current of the ounce circuit is about 25 amps; a1\"-wide 15 oz.

Trace can carry 200 amps in just 30 [degrees]C rise.

* Although the thickness of copper can vary by layer, the line/spacing is 3 miles per ounce.

Heavy copper can be asa-based copper of any thickness of 1/2 ounces. to 12 oz.

Compared to the final copper thickness, the thicker the base copper thickness, the less the plate and the cost.

Our cheap flexable flexible laminate is a limited alternative to flexible circuits and costs only a fraction of the cost. This FR-4-

The substrate thickness is from 0. 002\" (

Very flexible and flexible but limited robustness)to 0. 008 \"thickness (

No flex but stronger). Single-or double-

There are ED or RA foil on the side of this product.

This material can be used to replace the flex (i. e.

Not often bent)

The situation is not dynamic (

Repeated bending motion)state.

This product is for you if you are buying flex, using a harness, or asking the board to bend around the enclosure.

Quick fact: * double

Double sided products can pass through the hole-

Plated with copper thickness up to 12 ounces.

* Final finish available in gold, tin and tinlead.

A flexible welding mask is used.

* Flexable flex is a cheap alternative to flat cables and other lines (including high power busbars.

\"Join this revolution and open this page. . .

\"First of all, we ask our customers what they want to accomplish.

Then we dream, conceive, research, develop, test.

We have done what others think is impossible.

We are not satisfied with the development of printed circuits.

So we created the printing circuit revolution.

It\'s time.

Is the revolution ready? Call 1-800-763-7503, ext.

500 or visit www. protoexpress.

1108 West Evelyn Avenue

, Sunnyvale, CA 94086 Email: Archive @ protoexpress.

Visit us at PCB West 2005 (booth 1205)from March 7-11, 2005.

Custom message