safety problems plague circuit board industry

by:Rocket PCB

2019-09-04

Long before Jose Robles was working there, the warning sign for Tustin Circuits was clear.

The factory often smells of ammonia, causing many complaints from neighbors.

The state says toxic and incompatible chemicals are stored inside and are not marked and are adjacent to each other.

In the back room, a large bucket of acid sent out pungent smoke, so that the Anaheim Fire inspector who visited in May 1995 wrote: \"When I went in, it burned my

For Robles, 21year-

The old couple from Mexico, another danger is coming.

The rig he was operating lacked a guard.

According to Cal/OSHA, on July 1 last year, the young man\'s right forearm was crushed, two fingers were later amputated and Tustin Circuits was fined $22,000.

Tustin Circuits declined to comment and owners Py and Marvin Cha appealed the fine.

But Albert Sanchez, a former factory manager who resigned in last September, said: \"Robles is not trained and the equipment is old.

\"Robles\'s accident sounds terrible, but it doesn\'t surprise safety experts familiar with the emerging printed circuit board industry in Southern California, which now has the largest part of the industry.

Just a few years ago, the industry seemed to be in its final stages.

Although the board manufacturing industry grew up in California in its 60 s, thanks to Silicon Valley and the growing defense sector, manufacturers have begun to turn to lower levels in the past decade

Wage countries in Asia.

With the decline in military spending, California\'s employment in the industry fell third from 1988 to 1992.

Since then, however, driven by a surge in consumer demand for PCs, mobile phones and video games, the domestic industry has recovered rapidly.

As in the apparel industry, the job is back due to smaller orders that require fast turnaround and mid-term turnaround

Change in production.

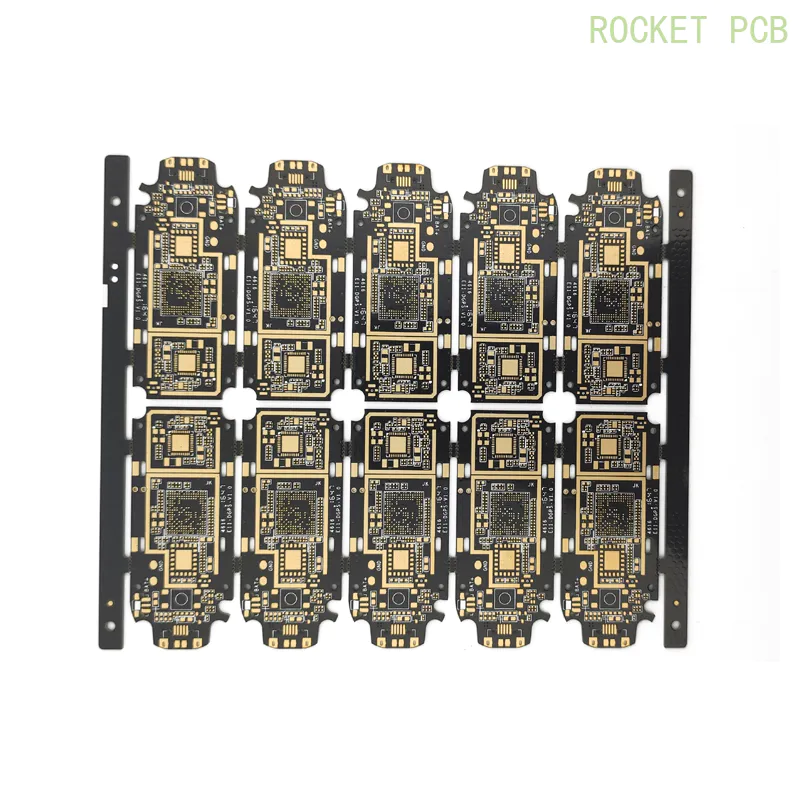

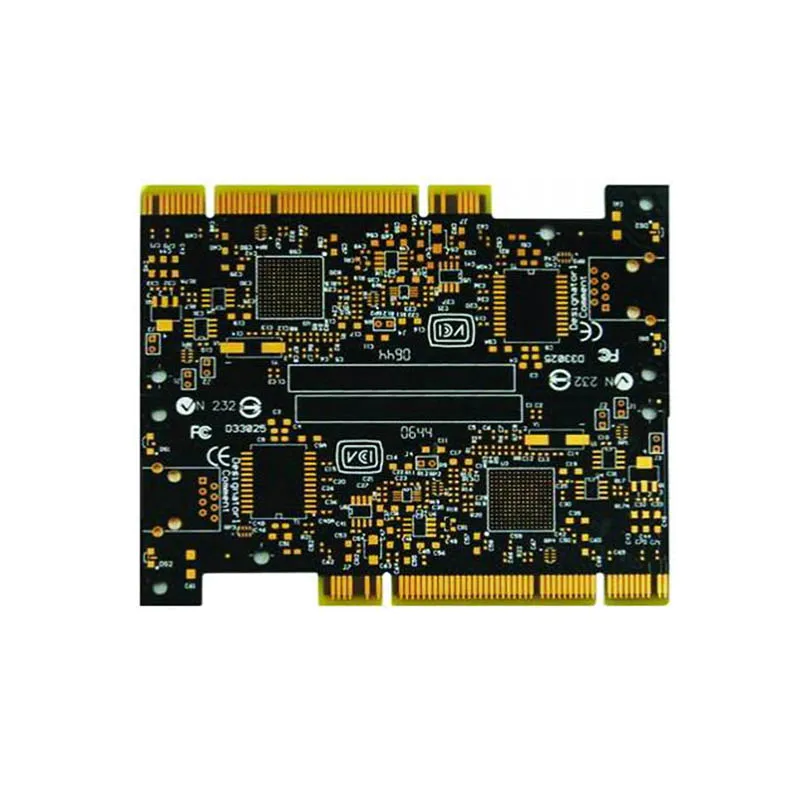

California currently has more than 26,000 people working in circuit board factories, most of them in Southern California, up 11% from four years ago, making it one of the fastest growing manufacturing industries.

But according to CAL/OSHA, board manufacturing is also one of the most dangerous industries around it, with inspection records and interviews showing that serious health and safety issues abound. That such high-

The presence of technology sweatshops seems to be inconsistent with the reputation of the precise and clean industry. But in circuit-

Plate production, especially in the early stages--

Workers cut panels, drill holes and apply solutions and acids--

Conditions away from dust-free.

In some shops, migrant workers work hard under hard, dirty conditions and earn very low wages, which reminds them of their previous times.

\"It\'s ugly, dirty, dangerous work,\" said Sam Richardson, industrial hygienist Cal/OSHA in Anaheim . \" He checked a dozen board companies last year.

\"There are more serious dangers that need to be addressed.

\"* The problem is not that there are a few large board manufacturers that dominate the industry in the region.

Experts say companies like Toppan in western San Diego tend to have highly automated processes and often run safe operations.

\"Overall, it\'s a pretty good-

Run the business, \"said Fred Friedman, vice president of Kirk --

Miller Alto is a company that does market research for the industry.

\"I don\'t think they are more guilty than other industries.

But Mom\'s scoreand-

Pop contractors fight for the crumbs of the industry, and it is on this brutal stage that shopkeepers cut corners on safety and environmental regulations to cut costs.

Most of the state\'s 550 PCB manufacturers are small businesses, shops that employ less than 20 workers, often hidden in light industry buildings in communities such as Santa Ana and Chatsworth, according to experts and business catalogues.

Many factory workers are immigrants and their tasks include etching, electroplating and welding, often involving hazardous chemicals.

The inspectors said that in some of the worst circuit board stores, the air was thick and smelly because the employer did not have the right ventilation system installed.

The carpet has been eaten with acid, and workers who do not have enough protection may be stung by splashes cooked with a 300 degree barrel of oil.

The bathroom was often dirty and the grass outside turned brown due to a chemical leak.

Budd Warshauer, a consultant at Huntington Beach, who advises board manufacturers on safety and environmental issues, is a frequent visitor to these stores.

\"They are outside, they exist, they weaken the legitimate business,\" he said . \".

California Safety and Health Agency Cal/OSHA lists board manufacturing as a high hazard industry along with forestry, coal mines and heavy-duty buildings.

But to a large extent, since the inspection was mainly caused by complaints, the radar of Cal/OSHA caused the board store to decline.

Workers are unlikely to blame employers in this immigration industry.

Although Cal/OSHA records show that there were only a dozen accidents in the circuit board stores in the last five years ended February, analysts said this was because industry insiders did not report injuries.

Taking Tustin circuit as an example, although all serious injuries should be reported, neither the worker nor the manager notified Cal/OSHA robles of the accident.

Cal/OSHA learned about amputations through interviews with workers and inquiries about the company worker compensation carrier.

* Some industry workers including Robles and his colleagues

Staff at Tustin Circuits do not want to be interviewed.

But security inspectors and company managers who spoke to them said workers were worried that they would lose their wages or take to the streets if they complained.

\"When you talk to these people, they say they\'re lucky to have a job and don\'t want to shake it,\" Richardson said . \".

\"So it\'s not reported and nobody cares about it.

Richardson said he checked more than a dozen times on the circuit board store on average 17 violations per store-

Eight times higher than the standards of all businesses.

Other inspectors who have visited board manufacturers have also reported high violations.

Among the most common problems, inspectors said: lack of staff training, inadequate equipment to protect workers from collision noise and acid splashes, unqualified eye wash and safe shower, and improper storage of toxic substances.

\"In this industry, it is not uncommon to find a store to take shortcuts in certain areas,\" said David Shapiro, sales and marketing director of senior control company, a company that sells machinery to circuit board manufacturers.

Nevertheless, Cal/OSHA records obtained through the Public Records Act show that inspections of the industry are accidental, with an average of only 30 stores per year during the decade.

At this rate, a store may receive a Cal/OSHA check every 18 years ---

The inspection frequency of the Garment contractor is less than half.

\"Why only focus on clothing?

\"David Bacon asked, he is a former electronics worker in Silicon Valley and an organizer of the Union of printed circuit board shop, few success.

Bacon recalled a case that attracted public attention at the end of 1992, when dozens of migrant workers in Sunnyvale Versatronex resigned after complaining about low wages and nosebleeds due to toxin work.

The workers at Versatronex finally won the union\'s approval, but the company responded by closing the plant.

There are other accidents worth noting. incidents.

Of the more than a dozen cases recorded by Cal/OSHA, one case was in mid-

1993 workers worked in a shop in the Highlands and 15 workers were taken to the hospital emergency room after complaining about headaches and nausea.

The workers were released later in the day and the New Bedford company received a general reference.

A year later, in another factory, ADI Isola Inc.

In the Bay Area, a worker named Jose Lopez was assigned to the mixer room to perform cleaning operations using toxic liquid PX that permeates the skin.

According to Cal/OSHA\'s report, Lopez worked with this chemical for 10 hours without a respirator and sufficient protective foot and body gear.

Lopez told Cal/OSHA that the chemical was soaked in his shoes and his feet changed color.

Lopez said he was sick the next day and vomited every hour all night.

He was diagnosed with chemical hepatitis when he went to the hospital and was hospitalized for 6 days.

Cal/OSHA said he returned to work a month later, although his liver test results indicated that he should not do so.

The company was cited for 19 violations, including 6 serious violations related to Lopez\'s injury and was fined $15,000. A follow-

Six months later, Cal/OSHA\'s upward visit found that ADI did not correct all the problems and it was again cited for five serious violations and fined $4,360.

The company did not call back but the record showed that all the fines had been paid.

The board business has always been a fierce business.

Many stores were born as a whole.

Apart from the scissors, welding guns and chemicals purchased at the hardware store, there is little personal operation.

\"This is one of the industries that some people do in the garage,\" said James Weigand, a hazardous materials specialist in Anaheim\'s fire department, who has checked many board businesses over the years.

\"They know about machinery, but they don\'t know about safety.

\"But because of the high cost of compliance, owners also ignore safety and other regulatory laws.

Experts say that in an industry with a meager profit margin, some people find non-compliance ---

The savings they can get from it. -worth the risk.

\"As the competition is getting more intense, you \'ve got people trying to cut corners,\" said Valerie Griswald, Deputy District Attorney for Orange County . \".

Investigators from Orange County\'s environmental protection department, Griswald and Kepp Kinnings, have long been chasing rogue board manufacturers.

Although they are careful not to portray it as a sneer industry, they note that they have done a lot of work and will encounter about once a month a new case of illegal chemical dumping.

In a recent case, the two brothers run a pair of related stores, Pentaflex of Pentadyne and priestia in Anaheim, earlier this year, felony charges of dumping acid and other metal waste into the sewer system were acknowledged.

At the end of last year, Cal/OSHA also cited Pentadyne for 17 violations.

The allegations include the failure to provide emergency showers, eye wash equipment and training on combustible materials and toxic acid treatment.

Since then, the company has moved to prisitia and continues to operate, but has not responded to calls seeking comment.

Aprandra Shah is one of them.

Time environment/safety manager at Velie Circuits, the company has 150 employees with annual sales of about $40 million.

Shah says his company spends about $10,000 a year on health and safety projects.

\"We have a lot of good equipment and most programs are automated,\" he said . \"

Some employees are equipped with computers that can drill holes, the diameter of these computers is as small as the diameter of human hair, they work in a sealed environment

Rooms in blue gowns, gloves and masks.

But in a recent visit to Cal/OSHA, Velie was accused of violating 24 provisions, including several serious provisions, and was assessed to be fined about $10,000.

The inspector\'s report said that the employee complained that the splash caused burns and that a worker wrapped paper and tape around his forearm to prevent the acid splash.

The company appealed the fine.

Shah said he provided training in addition to safety glasses, breathing apparatus and other protective equipment.

But workers don\'t always use them, he says.

\"I understand this is the responsibility of the company.

But on the other hand, companies cannot have children.

Sitting staff all day.

\"Cosmo Innamorato, quality control manager, rock industry, 35

The staff store at Huntington Beach says it\'s hard to keep up with all the safety and environmental regulations.

Innamorato has been working in the rock industry for the last 17 years, through boom and bust periods.

But till last May, 20-year-

The old company encountered a Cal/OSHA check for the first time.

The result was: 16 citations, although none of them were serious, with a fine of $3,600.

Innamorato said the fine had been paid and the violation was corrected.

But he complained that the citations were technical, such as The Wire was not suitable, or that the safe shower was not close enough to the production area.

Nevertheless, he said that the company installed a safe shower for $700 and thereafter hired a safety consultant to complete the entire 12,000-square-foot plant.

He said with a little reluctance that the consultant would cost about $60 an hour.

\"We found it difficult to compete with offshore stores, and some of them have to pay for security costs,\" he said . \".

The factory often smells of ammonia, causing many complaints from neighbors.

The state says toxic and incompatible chemicals are stored inside and are not marked and are adjacent to each other.

In the back room, a large bucket of acid sent out pungent smoke, so that the Anaheim Fire inspector who visited in May 1995 wrote: \"When I went in, it burned my

For Robles, 21year-

The old couple from Mexico, another danger is coming.

The rig he was operating lacked a guard.

According to Cal/OSHA, on July 1 last year, the young man\'s right forearm was crushed, two fingers were later amputated and Tustin Circuits was fined $22,000.

Tustin Circuits declined to comment and owners Py and Marvin Cha appealed the fine.

But Albert Sanchez, a former factory manager who resigned in last September, said: \"Robles is not trained and the equipment is old.

\"Robles\'s accident sounds terrible, but it doesn\'t surprise safety experts familiar with the emerging printed circuit board industry in Southern California, which now has the largest part of the industry.

Just a few years ago, the industry seemed to be in its final stages.

Although the board manufacturing industry grew up in California in its 60 s, thanks to Silicon Valley and the growing defense sector, manufacturers have begun to turn to lower levels in the past decade

Wage countries in Asia.

With the decline in military spending, California\'s employment in the industry fell third from 1988 to 1992.

Since then, however, driven by a surge in consumer demand for PCs, mobile phones and video games, the domestic industry has recovered rapidly.

As in the apparel industry, the job is back due to smaller orders that require fast turnaround and mid-term turnaround

Change in production.

California currently has more than 26,000 people working in circuit board factories, most of them in Southern California, up 11% from four years ago, making it one of the fastest growing manufacturing industries.

But according to CAL/OSHA, board manufacturing is also one of the most dangerous industries around it, with inspection records and interviews showing that serious health and safety issues abound. That such high-

The presence of technology sweatshops seems to be inconsistent with the reputation of the precise and clean industry. But in circuit-

Plate production, especially in the early stages--

Workers cut panels, drill holes and apply solutions and acids--

Conditions away from dust-free.

In some shops, migrant workers work hard under hard, dirty conditions and earn very low wages, which reminds them of their previous times.

\"It\'s ugly, dirty, dangerous work,\" said Sam Richardson, industrial hygienist Cal/OSHA in Anaheim . \" He checked a dozen board companies last year.

\"There are more serious dangers that need to be addressed.

\"* The problem is not that there are a few large board manufacturers that dominate the industry in the region.

Experts say companies like Toppan in western San Diego tend to have highly automated processes and often run safe operations.

\"Overall, it\'s a pretty good-

Run the business, \"said Fred Friedman, vice president of Kirk --

Miller Alto is a company that does market research for the industry.

\"I don\'t think they are more guilty than other industries.

But Mom\'s scoreand-

Pop contractors fight for the crumbs of the industry, and it is on this brutal stage that shopkeepers cut corners on safety and environmental regulations to cut costs.

Most of the state\'s 550 PCB manufacturers are small businesses, shops that employ less than 20 workers, often hidden in light industry buildings in communities such as Santa Ana and Chatsworth, according to experts and business catalogues.

Many factory workers are immigrants and their tasks include etching, electroplating and welding, often involving hazardous chemicals.

The inspectors said that in some of the worst circuit board stores, the air was thick and smelly because the employer did not have the right ventilation system installed.

The carpet has been eaten with acid, and workers who do not have enough protection may be stung by splashes cooked with a 300 degree barrel of oil.

The bathroom was often dirty and the grass outside turned brown due to a chemical leak.

Budd Warshauer, a consultant at Huntington Beach, who advises board manufacturers on safety and environmental issues, is a frequent visitor to these stores.

\"They are outside, they exist, they weaken the legitimate business,\" he said . \".

California Safety and Health Agency Cal/OSHA lists board manufacturing as a high hazard industry along with forestry, coal mines and heavy-duty buildings.

But to a large extent, since the inspection was mainly caused by complaints, the radar of Cal/OSHA caused the board store to decline.

Workers are unlikely to blame employers in this immigration industry.

Although Cal/OSHA records show that there were only a dozen accidents in the circuit board stores in the last five years ended February, analysts said this was because industry insiders did not report injuries.

Taking Tustin circuit as an example, although all serious injuries should be reported, neither the worker nor the manager notified Cal/OSHA robles of the accident.

Cal/OSHA learned about amputations through interviews with workers and inquiries about the company worker compensation carrier.

* Some industry workers including Robles and his colleagues

Staff at Tustin Circuits do not want to be interviewed.

But security inspectors and company managers who spoke to them said workers were worried that they would lose their wages or take to the streets if they complained.

\"When you talk to these people, they say they\'re lucky to have a job and don\'t want to shake it,\" Richardson said . \".

\"So it\'s not reported and nobody cares about it.

Richardson said he checked more than a dozen times on the circuit board store on average 17 violations per store-

Eight times higher than the standards of all businesses.

Other inspectors who have visited board manufacturers have also reported high violations.

Among the most common problems, inspectors said: lack of staff training, inadequate equipment to protect workers from collision noise and acid splashes, unqualified eye wash and safe shower, and improper storage of toxic substances.

\"In this industry, it is not uncommon to find a store to take shortcuts in certain areas,\" said David Shapiro, sales and marketing director of senior control company, a company that sells machinery to circuit board manufacturers.

Nevertheless, Cal/OSHA records obtained through the Public Records Act show that inspections of the industry are accidental, with an average of only 30 stores per year during the decade.

At this rate, a store may receive a Cal/OSHA check every 18 years ---

The inspection frequency of the Garment contractor is less than half.

\"Why only focus on clothing?

\"David Bacon asked, he is a former electronics worker in Silicon Valley and an organizer of the Union of printed circuit board shop, few success.

Bacon recalled a case that attracted public attention at the end of 1992, when dozens of migrant workers in Sunnyvale Versatronex resigned after complaining about low wages and nosebleeds due to toxin work.

The workers at Versatronex finally won the union\'s approval, but the company responded by closing the plant.

There are other accidents worth noting. incidents.

Of the more than a dozen cases recorded by Cal/OSHA, one case was in mid-

1993 workers worked in a shop in the Highlands and 15 workers were taken to the hospital emergency room after complaining about headaches and nausea.

The workers were released later in the day and the New Bedford company received a general reference.

A year later, in another factory, ADI Isola Inc.

In the Bay Area, a worker named Jose Lopez was assigned to the mixer room to perform cleaning operations using toxic liquid PX that permeates the skin.

According to Cal/OSHA\'s report, Lopez worked with this chemical for 10 hours without a respirator and sufficient protective foot and body gear.

Lopez told Cal/OSHA that the chemical was soaked in his shoes and his feet changed color.

Lopez said he was sick the next day and vomited every hour all night.

He was diagnosed with chemical hepatitis when he went to the hospital and was hospitalized for 6 days.

Cal/OSHA said he returned to work a month later, although his liver test results indicated that he should not do so.

The company was cited for 19 violations, including 6 serious violations related to Lopez\'s injury and was fined $15,000. A follow-

Six months later, Cal/OSHA\'s upward visit found that ADI did not correct all the problems and it was again cited for five serious violations and fined $4,360.

The company did not call back but the record showed that all the fines had been paid.

The board business has always been a fierce business.

Many stores were born as a whole.

Apart from the scissors, welding guns and chemicals purchased at the hardware store, there is little personal operation.

\"This is one of the industries that some people do in the garage,\" said James Weigand, a hazardous materials specialist in Anaheim\'s fire department, who has checked many board businesses over the years.

\"They know about machinery, but they don\'t know about safety.

\"But because of the high cost of compliance, owners also ignore safety and other regulatory laws.

Experts say that in an industry with a meager profit margin, some people find non-compliance ---

The savings they can get from it. -worth the risk.

\"As the competition is getting more intense, you \'ve got people trying to cut corners,\" said Valerie Griswald, Deputy District Attorney for Orange County . \".

Investigators from Orange County\'s environmental protection department, Griswald and Kepp Kinnings, have long been chasing rogue board manufacturers.

Although they are careful not to portray it as a sneer industry, they note that they have done a lot of work and will encounter about once a month a new case of illegal chemical dumping.

In a recent case, the two brothers run a pair of related stores, Pentaflex of Pentadyne and priestia in Anaheim, earlier this year, felony charges of dumping acid and other metal waste into the sewer system were acknowledged.

At the end of last year, Cal/OSHA also cited Pentadyne for 17 violations.

The allegations include the failure to provide emergency showers, eye wash equipment and training on combustible materials and toxic acid treatment.

Since then, the company has moved to prisitia and continues to operate, but has not responded to calls seeking comment.

Aprandra Shah is one of them.

Time environment/safety manager at Velie Circuits, the company has 150 employees with annual sales of about $40 million.

Shah says his company spends about $10,000 a year on health and safety projects.

\"We have a lot of good equipment and most programs are automated,\" he said . \"

Some employees are equipped with computers that can drill holes, the diameter of these computers is as small as the diameter of human hair, they work in a sealed environment

Rooms in blue gowns, gloves and masks.

But in a recent visit to Cal/OSHA, Velie was accused of violating 24 provisions, including several serious provisions, and was assessed to be fined about $10,000.

The inspector\'s report said that the employee complained that the splash caused burns and that a worker wrapped paper and tape around his forearm to prevent the acid splash.

The company appealed the fine.

Shah said he provided training in addition to safety glasses, breathing apparatus and other protective equipment.

But workers don\'t always use them, he says.

\"I understand this is the responsibility of the company.

But on the other hand, companies cannot have children.

Sitting staff all day.

\"Cosmo Innamorato, quality control manager, rock industry, 35

The staff store at Huntington Beach says it\'s hard to keep up with all the safety and environmental regulations.

Innamorato has been working in the rock industry for the last 17 years, through boom and bust periods.

But till last May, 20-year-

The old company encountered a Cal/OSHA check for the first time.

The result was: 16 citations, although none of them were serious, with a fine of $3,600.

Innamorato said the fine had been paid and the violation was corrected.

But he complained that the citations were technical, such as The Wire was not suitable, or that the safe shower was not close enough to the production area.

Nevertheless, he said that the company installed a safe shower for $700 and thereafter hired a safety consultant to complete the entire 12,000-square-foot plant.

He said with a little reluctance that the consultant would cost about $60 an hour.

\"We found it difficult to compete with offshore stores, and some of them have to pay for security costs,\" he said . \".

Custom message