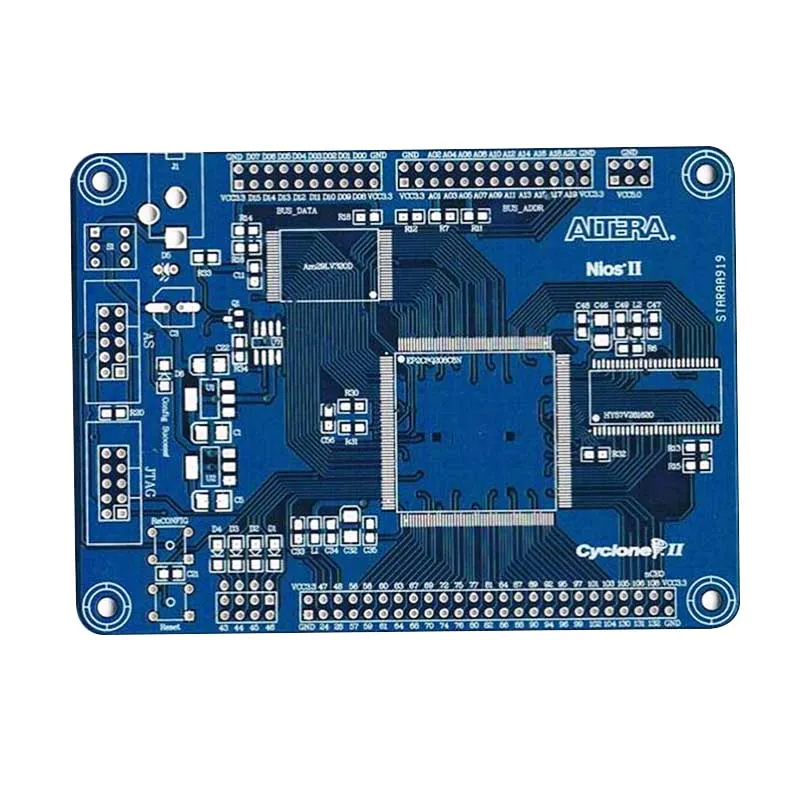

Introduction to Double-sided PCB manufacturing process

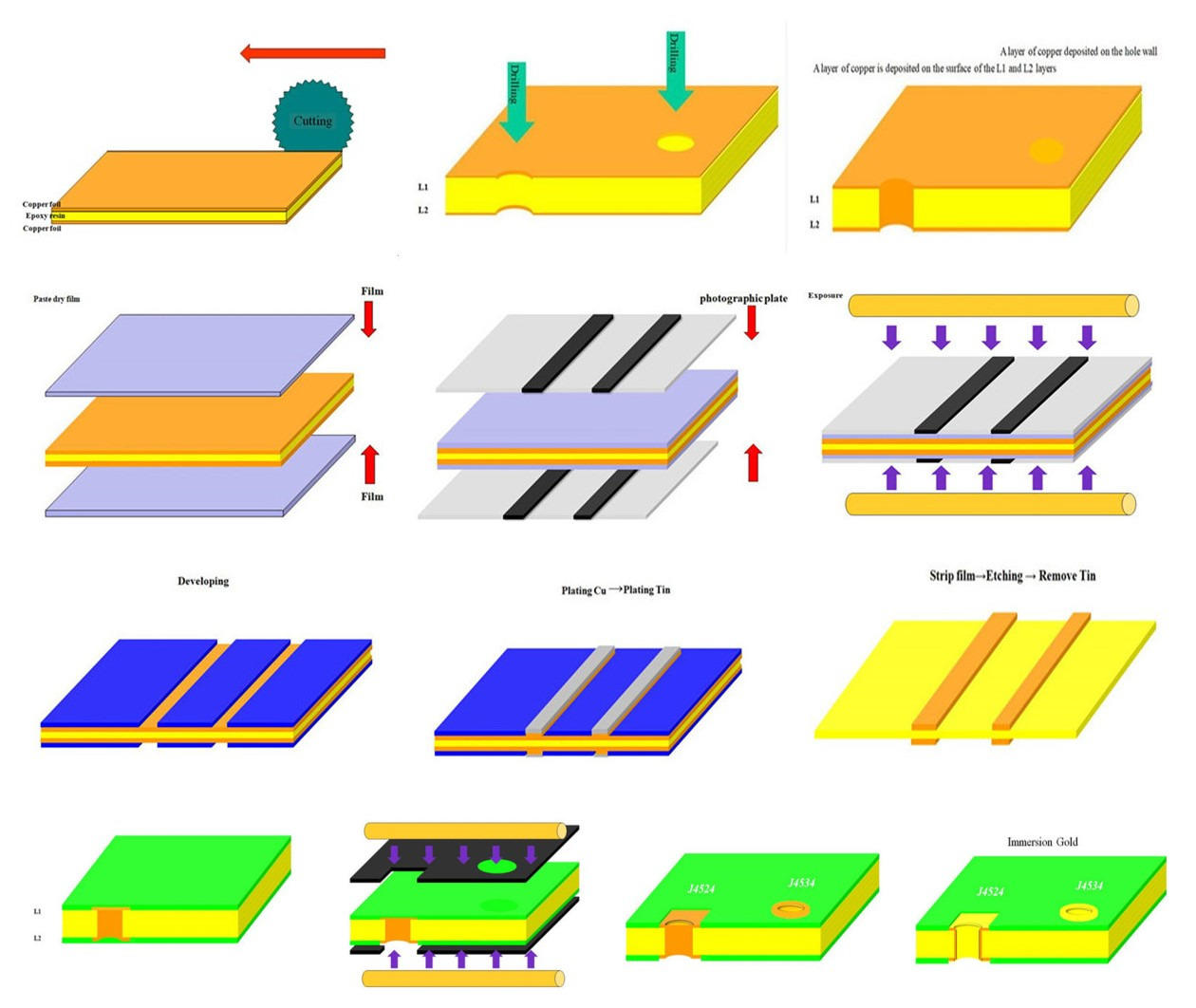

Customer requirements → engineering design materials → production work order MI→material cutting→baking board → drilling → electroless plating copper(PTH) →copper surface plating→ grinding Brush→ pattern exposure → develop→plating copper and tin →strip film→ etching → strip tin →soldermask→Immersion Gold→Routing→ET→HASL→FQC→warehouse

1, Cutting Material: Cut out easy-to-process dimensions from the whole sheet of copper clad laminate (CCL) with a certain thickness and foil thickness

2, Drilling: Drilling a conductive hole or plug-in hole on the board according to the computer drilling program

3, PTH: A thin layer of chemical copper is deposited in the drilled hole, with the aim of sinking a layer of copper through chemical methods in non-conductive epoxy glass cloth substrates (or other substrates), making it easy for the rear plating guide to form the circuit pattern;

4, Full Plate Copper Plating: The main purpose is to protect the thin layer of chemical copper from oxidation in the air, forming no copper or holes in the holes.

5, Circuits (graphics transfer) is pasted with dry film on board. After exposure and development, circuit graphics are made.

6, Pattern plating: Wire copper thickening plating on pattern circuit, so that the hole and pattern copper thickness reached a certain thickness, can load a certain amount of current

7, Etching: Fade The graphics ink or dry film, etching off the excess copper foil to obtain conductive line graphics. Remove the pattern ink or dry film, etch out the excess copper foil to get the conductive graphics

8, Remove tin: The tin layer on the formed graph is removed to reveal the required pattern

9, Silk screen soldermask or paste soldermask dry film: Printing a layer of soldermask ink on the board, or affixed with a layer of soldermask dry film, after exposure, development to form soldermask layer, the main purpose is to prevent short circuit between the lines at the time of soldering

10, Immersion Gold/HASL: Immersion gold or spray a layer of tin on the board where it needs to be welded, making it easy to solder, while also preventing oxidation of the copper surface at the place

11, Silkscreen: printing some iconic words on the board, mainly convenient for customers to install components

12, Routing: Process the profile of the Board

13, Electrical test: Detecting whether there is an open short circuit in the PCB by means of a closed loop

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink