SPECIALIZED MANUFACTURING

Conductive materials and core-to-core bonding

Embedded components

RF connector attachment

Laser direct imaging (LDI)

Laser etching

Laser forming

Multi-level cavity construction

Plated cavities and edges

Composite/hybrid Structures

N+N dual press-fit

Dual-drill

Bonding on metal core

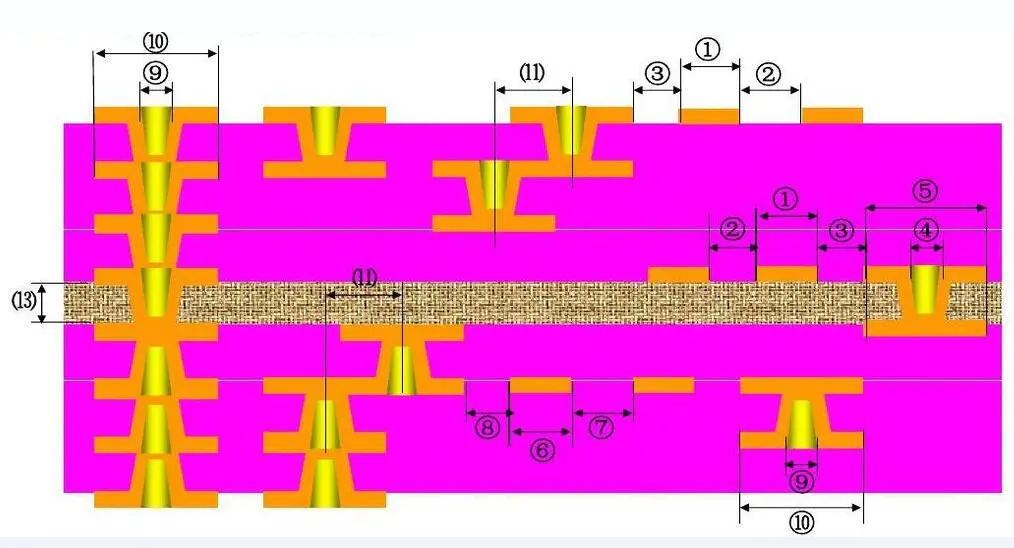

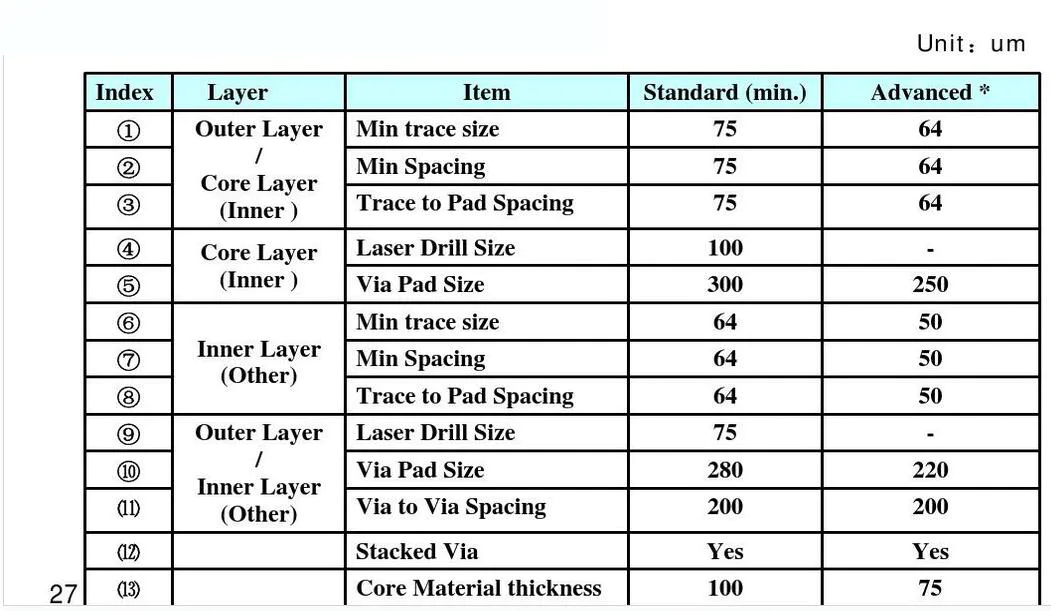

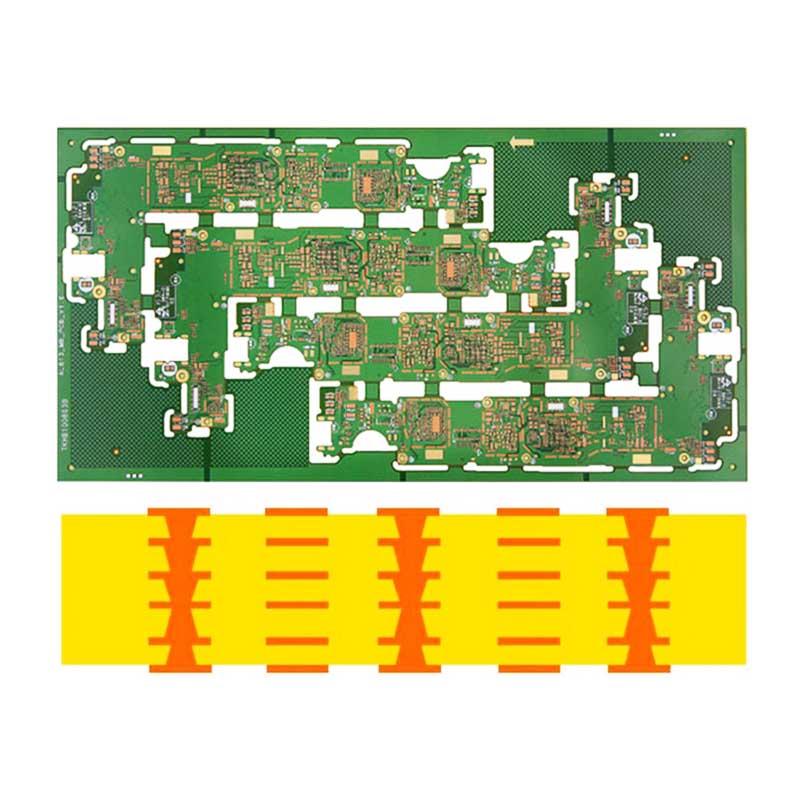

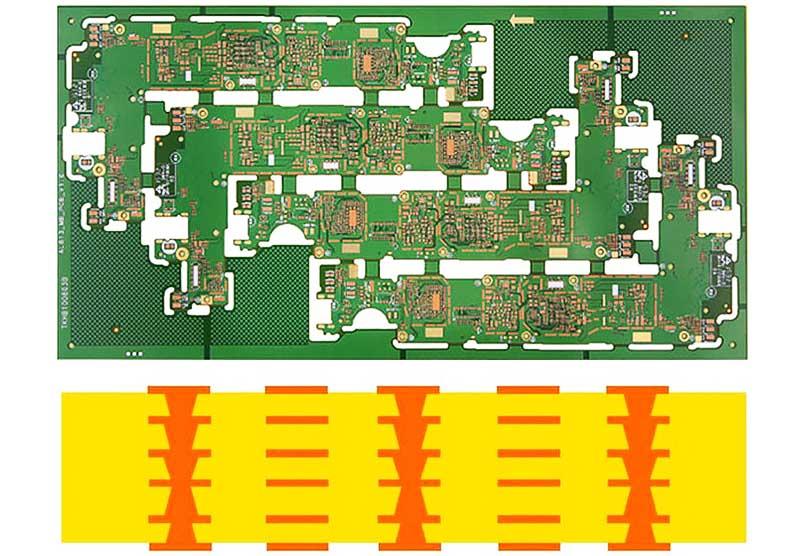

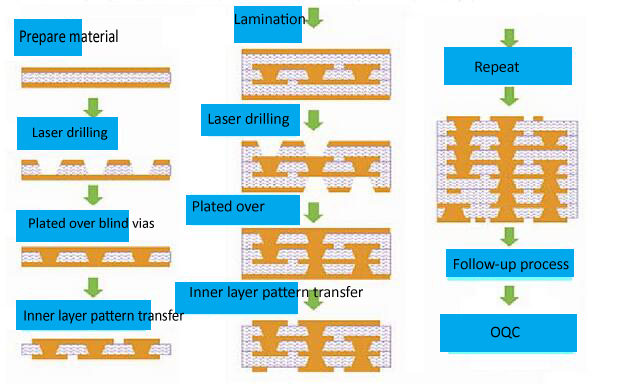

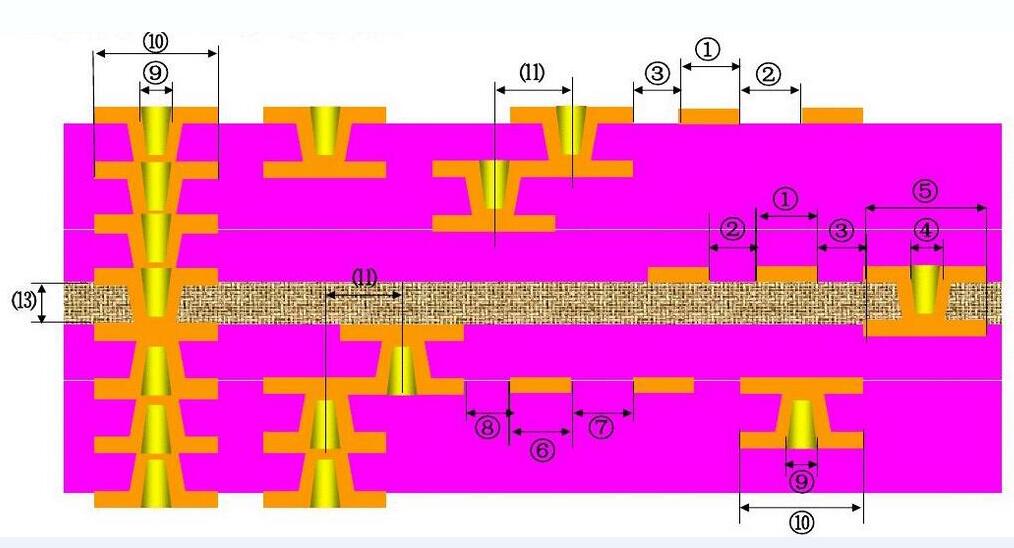

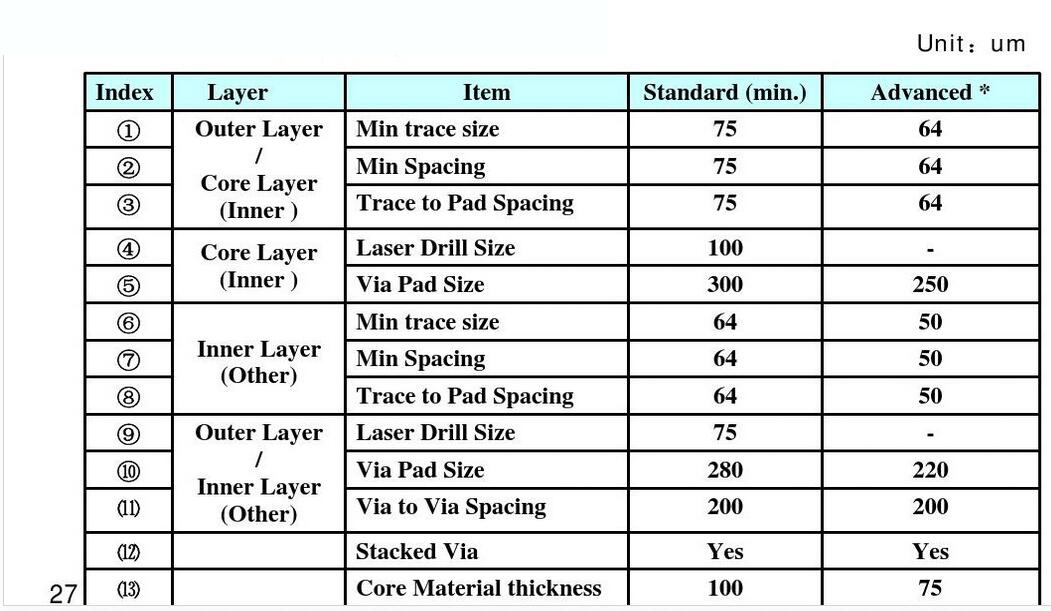

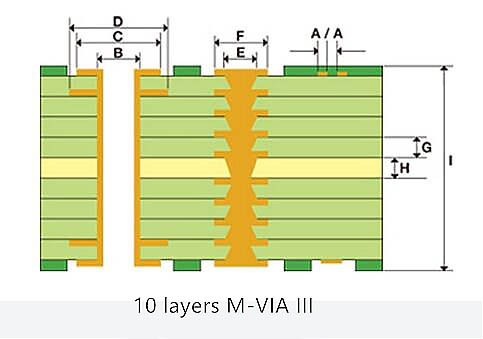

Bulid-up HDI

Long-short and staged gold finger

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF contro