qualifying pcbs outsourced in asia: communication, documentation and teamwork between suppliers reduces the risk and increases the benefits of outsourcing.

by:Rocket PCB

2019-11-26

The growth of portable wireless products and related consumer electronics has driven significant outsourcing efforts in Asia. Most OEMs(

Original Equipment Manufacturer)

Cooperate with CMs (

Contract manufacturer)

Outsourcing key business such as circuit board design, manufacturing, surface treatment in Asia

Assemble and purchase to maintain profitability and competitive advantage.

Outsourcing can provide significant advantages for OEMs in maintaining healthy profits, including reducing capital risks, increasing access to current technologies, and reducing time-to-market.

Outsourcing also allows CMs and EMS (

Electronic Manufacturing Services

Companies subcontract jobs that do not match their core competencies so that they can diversify their products.

Outsourcing with strategic partners is more important for OEMsdealing and leads

The free migration from this new demand poses many challenges to the PCB lab and assembly industry.

New high TG (

Glass transition temperature)

New lead laminate

The entire manufacturing process requires careful evaluation of the new laminate to balance the assembly layout and optimization of the return profile, thus minimizing damage to the pcb.

This is particularly critical for pcb (less than 0. 1 mm)

For mobile phones and other portable products, as well as build-based pcb

Microvia technology.

The products needed in the handheld wireless market are small, thin and low.

The cost and weight are light through the improved user interface.

In addition, the integration of handheld wireless phones with handheld computers and Internet access is accelerating the demand for functional circuits. Cost technology.

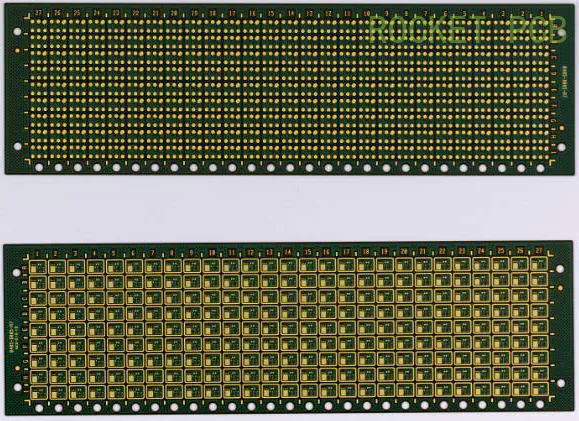

Outsourcing pcb from Asia for high participation-

Mass manufacturing.

Proper evaluation and identification of these facilities is essential for assembly reliability.

There are some key aspects in the identification of PCBs.

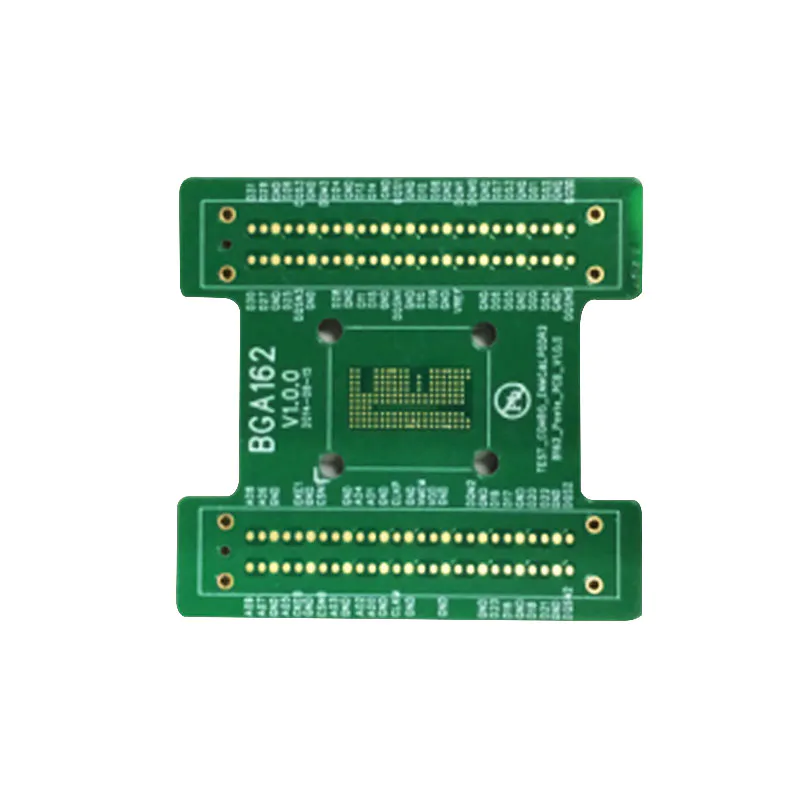

Index of human development identified (high-

Density Interconnect(1)and ALIVH (

Through any layer inside the hole)PCBs (2)

Purchasing from Asian manufacturers in China, Taiwan, South Korea and Japan requires a specific description.

Quality System audit results, PCB evaluation, acceptance criteria, DPPM (

A million difference)

Review and reliability testing are required.

In addition, strategies to overcome cultural differences, communicate, resolve conflicts, and build relationships between suppliers and customers are of high importance. High-volume surface-

Assembly production needs to be carefully evaluated as assembly production depends to a large extent on high-quality pcb, tin paste printing process and oven return curves.

This has become the key to lead-

Free return due to higher peak temperatures and narrow process windows.

In order to obtain good yield and reliability, proper storage, processing control and production process control in the supply chain are necessary.

Efforts to reduce DPPM must focus not only on the manufacturing process, but also on overcoming many cultural, communication and interpretation differences.

Supplier audit and qualification work requires a factory and warehouse visit and a quality system audit of the PCB manufacturing process.

Key projects such as ISO 9001-

2000 certifications, competency surveys, employee training and certification, eight disciplinary processes, design management and material control were reviewed.

Based on this review, four categories of customer satisfaction, manufacturing process, material management and quality system were ranked.

The supplier is then certified for production based on the aminimum score of 90% or higher as shown in Figure 1. [

Figure 1 slightly]

Most manufacturers in Asia have a certain proportion of outsourcing.

It is important to understand the manufacturing process of the product or technology and to investigate any subcontracting operations during the audit process, as the process control implemented will also affect the final product.

In this case, all action items generated by the audit are closed within five working days.

It is also important to track annual quality audits.

Product qualification.

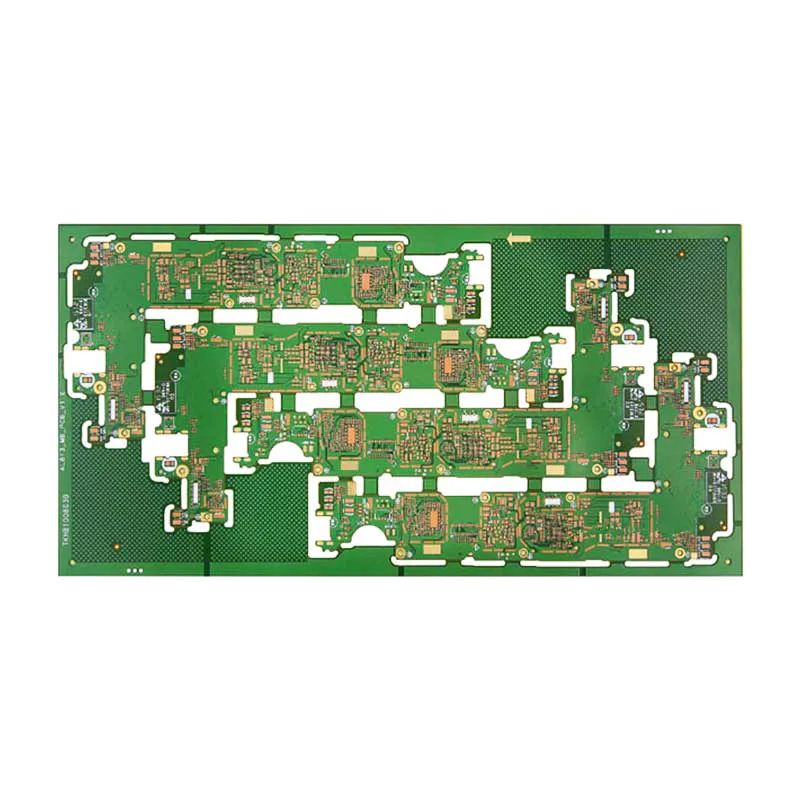

Board assembly process through dual certificationsided, surface-

Installation and assembly welding of BGA (ball gridarray)

Components such as packaging, connectors, chip resistors, capacitors, diodes, etc.

Assembly reflux using convection air at a temperature of 244 [apeak]degrees]C.

Assemble solder paste using wasSAC 305 (

Tin/Silver/copper)no-clean version. (3)Cross-

Segmentation of the BGA package and other components to evaluate the quality of the solder joints and to ensure compliance with ipc 610--

IPC 7095 for the Rev D and BGA packages of the lead package.

The integrity of Microvia was also assessed by cross-examination

Segmentation analysis. Cross-

The slices show no degradation of acceptable solder joints and microorganisms. (3, 4)

The qualification process is product build and cross-cutting using the aphone project

Segmentation analysis and reliability testing of PerIPC 9701. (5)

I did a temperature and humidity test on [85]degrees]

C lasts 85% hours at 500 relative humidity, from-25[degrees]C to +125[degrees]

C. 500 cycles in 20 minutes.

Figure 2 shows the crossover

Part of the reflow after assembly of the HDI circuit board, Figure 3 shows the portion of the reflux after assembly of the alivn PCB. [

Figure 2:

Rework process surface-

Heavy processing of loading bags using heat

Rework air welding tools and BGA packages with hot air using controlled slopes/soakprofile.

The main concern is that the microvia connection and PCBpads are damaged during the removal and reconnection of components.

Two parts rework was done on the lead package, and one rework was done on BGAs.

All the packages have undergone rework.

During the rework process, the PCB pads were not damaged and there was no looseness of the welding mask.

No harm to microorganisms was found.

Figure 4 and 5 show cross

After 500 thermal shock cycles, the parts of the HDI and alivn crash Post were reworked. [

Figure 3 slightly]

There are two types of production rejection for production DPPM issues.

Cosmetic rejection is rejected in the IQC inspection and functional rejection of incoming goods, in which the batch is rejected after return (after surface-mount assembly)

During the board

Horizontal electrical test. [

Figure 4 slightly]

Rejection of cosmetics

Purchase inspection using IPC 600Rev G.

Many products have been rejected due to incorrect paperwork, scratches, exposed copper, etc.

A meeting was held with suppliers and CMs to solve the problem;

After that, the supplier developed a plan to solve scratches and bare copper, reducing the mistake of CM.

Kyocera Wireless(KWC)

The team reviews the supplier\'s corrective actions.

In order to minimize pcb problems on the surface, there are several other process flow and material handling issues that need to be addressed

Installation production.

Prior to assembly outsourcing, PCBs were shipped from suppliers to KWC in San Diego, California, and were immediately used for production, so staging and storage were minimal.

This will change when the surface changes

In China, factories began to manufacture.

Due to customs requirements, all parts shipped to China must pass through customs in Hong Kong and then be moved in warehouse facilities until they are ready to be transferred to the warehouse in CM, thus increasing the transit time and processing of PCBs.

Suppliers are required to improve packaging, from standard plastic bags to professional seamless bags sealed with desiccant vacuum.

This requires some changes to the PCB package, but it is more reliable in the long run.

The warehouse audit is to ensure that the temperature is maintained at 22 [degrees]C +/-5[degrees]

C with humidity less than 60%

In this geographic area, pay special attention to storage when it is very hot and humid. [

Figure 5 Slightly]

Feature rejection.

Defects after reflux are mainly divided into three categories: opening, layering and short circuit.

This requires a review of the handling and testing operations of the CMs as well as the process control of the supplier.

Corrective action begins with the compilation of defect data and meetings with suppliers and CM.

A storage and processing audit was followed to ensure corrective actions were properly implemented.

Manufacturers implement corrective actions in the PCB packaging area by changing the baking cycle to 120 [degrees]

C 4 hours before dry packing.

CMimplemented implemented corrective actions at IQC by re-sealing all packaging for open checks before returning to storage.

In the production workshop, the packaging is only opened before loading on the assembly line, and all open packaging is stored in a dry box.

Return assembly time is controlled within 48 hours.

Warehouse corrective actions have been implemented to store the pcb in the controlled temperature/humidity section of the warehouse and first out (

First out first)was enforced.

In order to solve the problem of layering, the PCB supplier has carried out experimental design (DOE)

Work with their material suppliers to better understand the processing of high TG laminate.

By implementing controls as well as various other plating and cleaning tank parameters and controls during the chemical plating process, the problem of circuit tracking \"on\" is solved.

Also, in hot-

The air rework process for CM, as some \"open\" issues occur after rework.

Proper training of rework operators to control the distance of hot air nozzles and airflow, as well as continuous audits, further helps to reduce open DPPMCircuit defect.

By controlling contamination during pcb exposure, development and etching, and implementing appropriate sampling frequency to minimize escape to CM, the short circuit problem is solved. [

Figure 6 slightly]

All of these joint efforts help reduce the post-DPPM process and minimize scrap costs.

Communication strategy when switching from in-

For overseas manufacturers, some time, distance and translation difficulties will be added when solving daily line problems.

As an OEM, it is essential to keep the documentation correct and updated, as the error message can result in loss of production, delay in shipping to the customer, and refund from the OEM.

PCB is a complex commodity.

When parts are rejected, a good understanding of the PCB manufacturing process, acceptance criteria, defect failure analysis and root cause determination is required.

Since CM does not have a knowledgeable PCB team, the OEMcomponent engineer must mediate when a rejection occurs.

This helps both parties (

CM and PCB suppliers)

Understand the defects and develop improvement plans.

The first step is to hold a supplier meeting where CM understands the IQC specifications and acceptance criteria of CM.

Simple problems caused by incorrect paperwork, labeling, crossover

After understanding the IQC specifications, out and other issues were excluded.

IQC\'s Lotto rate increased to 100% in six months.

Subsequently, monthly DPPM data was provided to suppliersconferences.

For major issues, the supplier needs to provide up to five failed samples for fault analysis.

In addition, every quarter, all parties meet at CM factory to review DPPM and defects.

This gives the supplier the opportunity to meet with the CM team to learn about assembly operations and parts mobile programs.

The supplier team reviewed the failure analysis data and developed a corrective action plan.

To help the supplier team find the root cause of the defect, specific information is provided instead of the general DPPM bar chart.

The DPPM data is broken down into the first three defects and the first three parts numbers that have problems, enabling the supplier to first \"root cause\" major problems and minimize their impact on production

An example is shown in Figures 6 and 7.

Conflict Resolution CM\'s differences in operations, part management, refund systems, and language did lead to a conflict about waste charges.

In these cases, the OEM must intervene and ensure a fair resolution of the refund.

To ensure the correct root cause is determined, the fault analysis is evaluated.

If it is a supplier manufacturing problem, a fee is charged to the supplier.

If it\'s a process

Defects such as uncontrollable rework are induced and CM charges are charged.

If both parties contribute, the cost is separate.

The labor force at the CM factory is mainly a very young group with not much experience or training time.

Proper monitoring of training levels is important for good yield and product reliability.

This is also essential because of the departure of employees.

All process changes and engineering change orders should be strictly controlled (ECOs)

Manufacturing change order (MCOs), etc. OEM-

Led training courses in product processing, testing, storage and inspection have also increased production.

Conclusion outsourcing assembly operation makes the original equipment manufacturers have high

The development direction of large-scale database system and enterprise.

However, it also brings us many new challenges, such as cultural differences, communication barriers and skill levels. S.

PCB manufacturing.

Clear, coordinated communication, documentation, patience and teamwork between vendors and CMs are just a few ways to ensure success. REFERENCES (1)

Microvias for low cost, high density interconnect. John H. Lau,S. W. Ricky Lee. (2)

Progress of the Aliv substrate. Daizo A. , Yoshihiro T. ,Tadashi N. , Fumio E. (3)IPC A-610 Rev D--

Acceptability of electronic components. (4)IPC 7095--

Design and assembly process implementation of BGAs. (5)IPC 9701--

Performance test methods and quality requirements for surface mount welding accessories. (6)

SMT \"control and stability of lead-free reflow \". R. Burke, Sept. 2006, Vol. 20, No. 9, pp. 24-26, 28. MUMTAZ Y.

BORA is the chief quality engineer at Kyocera Wireless.

And can reach mbora @ Kyocerawire less. com.

Original Equipment Manufacturer)

Cooperate with CMs (

Contract manufacturer)

Outsourcing key business such as circuit board design, manufacturing, surface treatment in Asia

Assemble and purchase to maintain profitability and competitive advantage.

Outsourcing can provide significant advantages for OEMs in maintaining healthy profits, including reducing capital risks, increasing access to current technologies, and reducing time-to-market.

Outsourcing also allows CMs and EMS (

Electronic Manufacturing Services

Companies subcontract jobs that do not match their core competencies so that they can diversify their products.

Outsourcing with strategic partners is more important for OEMsdealing and leads

The free migration from this new demand poses many challenges to the PCB lab and assembly industry.

New high TG (

Glass transition temperature)

New lead laminate

The entire manufacturing process requires careful evaluation of the new laminate to balance the assembly layout and optimization of the return profile, thus minimizing damage to the pcb.

This is particularly critical for pcb (less than 0. 1 mm)

For mobile phones and other portable products, as well as build-based pcb

Microvia technology.

The products needed in the handheld wireless market are small, thin and low.

The cost and weight are light through the improved user interface.

In addition, the integration of handheld wireless phones with handheld computers and Internet access is accelerating the demand for functional circuits. Cost technology.

Outsourcing pcb from Asia for high participation-

Mass manufacturing.

Proper evaluation and identification of these facilities is essential for assembly reliability.

There are some key aspects in the identification of PCBs.

Index of human development identified (high-

Density Interconnect(1)and ALIVH (

Through any layer inside the hole)PCBs (2)

Purchasing from Asian manufacturers in China, Taiwan, South Korea and Japan requires a specific description.

Quality System audit results, PCB evaluation, acceptance criteria, DPPM (

A million difference)

Review and reliability testing are required.

In addition, strategies to overcome cultural differences, communicate, resolve conflicts, and build relationships between suppliers and customers are of high importance. High-volume surface-

Assembly production needs to be carefully evaluated as assembly production depends to a large extent on high-quality pcb, tin paste printing process and oven return curves.

This has become the key to lead-

Free return due to higher peak temperatures and narrow process windows.

In order to obtain good yield and reliability, proper storage, processing control and production process control in the supply chain are necessary.

Efforts to reduce DPPM must focus not only on the manufacturing process, but also on overcoming many cultural, communication and interpretation differences.

Supplier audit and qualification work requires a factory and warehouse visit and a quality system audit of the PCB manufacturing process.

Key projects such as ISO 9001-

2000 certifications, competency surveys, employee training and certification, eight disciplinary processes, design management and material control were reviewed.

Based on this review, four categories of customer satisfaction, manufacturing process, material management and quality system were ranked.

The supplier is then certified for production based on the aminimum score of 90% or higher as shown in Figure 1. [

Figure 1 slightly]

Most manufacturers in Asia have a certain proportion of outsourcing.

It is important to understand the manufacturing process of the product or technology and to investigate any subcontracting operations during the audit process, as the process control implemented will also affect the final product.

In this case, all action items generated by the audit are closed within five working days.

It is also important to track annual quality audits.

Product qualification.

Board assembly process through dual certificationsided, surface-

Installation and assembly welding of BGA (ball gridarray)

Components such as packaging, connectors, chip resistors, capacitors, diodes, etc.

Assembly reflux using convection air at a temperature of 244 [apeak]degrees]C.

Assemble solder paste using wasSAC 305 (

Tin/Silver/copper)no-clean version. (3)Cross-

Segmentation of the BGA package and other components to evaluate the quality of the solder joints and to ensure compliance with ipc 610--

IPC 7095 for the Rev D and BGA packages of the lead package.

The integrity of Microvia was also assessed by cross-examination

Segmentation analysis. Cross-

The slices show no degradation of acceptable solder joints and microorganisms. (3, 4)

The qualification process is product build and cross-cutting using the aphone project

Segmentation analysis and reliability testing of PerIPC 9701. (5)

I did a temperature and humidity test on [85]degrees]

C lasts 85% hours at 500 relative humidity, from-25[degrees]C to +125[degrees]

C. 500 cycles in 20 minutes.

Figure 2 shows the crossover

Part of the reflow after assembly of the HDI circuit board, Figure 3 shows the portion of the reflux after assembly of the alivn PCB. [

Figure 2:

Rework process surface-

Heavy processing of loading bags using heat

Rework air welding tools and BGA packages with hot air using controlled slopes/soakprofile.

The main concern is that the microvia connection and PCBpads are damaged during the removal and reconnection of components.

Two parts rework was done on the lead package, and one rework was done on BGAs.

All the packages have undergone rework.

During the rework process, the PCB pads were not damaged and there was no looseness of the welding mask.

No harm to microorganisms was found.

Figure 4 and 5 show cross

After 500 thermal shock cycles, the parts of the HDI and alivn crash Post were reworked. [

Figure 3 slightly]

There are two types of production rejection for production DPPM issues.

Cosmetic rejection is rejected in the IQC inspection and functional rejection of incoming goods, in which the batch is rejected after return (after surface-mount assembly)

During the board

Horizontal electrical test. [

Figure 4 slightly]

Rejection of cosmetics

Purchase inspection using IPC 600Rev G.

Many products have been rejected due to incorrect paperwork, scratches, exposed copper, etc.

A meeting was held with suppliers and CMs to solve the problem;

After that, the supplier developed a plan to solve scratches and bare copper, reducing the mistake of CM.

Kyocera Wireless(KWC)

The team reviews the supplier\'s corrective actions.

In order to minimize pcb problems on the surface, there are several other process flow and material handling issues that need to be addressed

Installation production.

Prior to assembly outsourcing, PCBs were shipped from suppliers to KWC in San Diego, California, and were immediately used for production, so staging and storage were minimal.

This will change when the surface changes

In China, factories began to manufacture.

Due to customs requirements, all parts shipped to China must pass through customs in Hong Kong and then be moved in warehouse facilities until they are ready to be transferred to the warehouse in CM, thus increasing the transit time and processing of PCBs.

Suppliers are required to improve packaging, from standard plastic bags to professional seamless bags sealed with desiccant vacuum.

This requires some changes to the PCB package, but it is more reliable in the long run.

The warehouse audit is to ensure that the temperature is maintained at 22 [degrees]C +/-5[degrees]

C with humidity less than 60%

In this geographic area, pay special attention to storage when it is very hot and humid. [

Figure 5 Slightly]

Feature rejection.

Defects after reflux are mainly divided into three categories: opening, layering and short circuit.

This requires a review of the handling and testing operations of the CMs as well as the process control of the supplier.

Corrective action begins with the compilation of defect data and meetings with suppliers and CM.

A storage and processing audit was followed to ensure corrective actions were properly implemented.

Manufacturers implement corrective actions in the PCB packaging area by changing the baking cycle to 120 [degrees]

C 4 hours before dry packing.

CMimplemented implemented corrective actions at IQC by re-sealing all packaging for open checks before returning to storage.

In the production workshop, the packaging is only opened before loading on the assembly line, and all open packaging is stored in a dry box.

Return assembly time is controlled within 48 hours.

Warehouse corrective actions have been implemented to store the pcb in the controlled temperature/humidity section of the warehouse and first out (

First out first)was enforced.

In order to solve the problem of layering, the PCB supplier has carried out experimental design (DOE)

Work with their material suppliers to better understand the processing of high TG laminate.

By implementing controls as well as various other plating and cleaning tank parameters and controls during the chemical plating process, the problem of circuit tracking \"on\" is solved.

Also, in hot-

The air rework process for CM, as some \"open\" issues occur after rework.

Proper training of rework operators to control the distance of hot air nozzles and airflow, as well as continuous audits, further helps to reduce open DPPMCircuit defect.

By controlling contamination during pcb exposure, development and etching, and implementing appropriate sampling frequency to minimize escape to CM, the short circuit problem is solved. [

Figure 6 slightly]

All of these joint efforts help reduce the post-DPPM process and minimize scrap costs.

Communication strategy when switching from in-

For overseas manufacturers, some time, distance and translation difficulties will be added when solving daily line problems.

As an OEM, it is essential to keep the documentation correct and updated, as the error message can result in loss of production, delay in shipping to the customer, and refund from the OEM.

PCB is a complex commodity.

When parts are rejected, a good understanding of the PCB manufacturing process, acceptance criteria, defect failure analysis and root cause determination is required.

Since CM does not have a knowledgeable PCB team, the OEMcomponent engineer must mediate when a rejection occurs.

This helps both parties (

CM and PCB suppliers)

Understand the defects and develop improvement plans.

The first step is to hold a supplier meeting where CM understands the IQC specifications and acceptance criteria of CM.

Simple problems caused by incorrect paperwork, labeling, crossover

After understanding the IQC specifications, out and other issues were excluded.

IQC\'s Lotto rate increased to 100% in six months.

Subsequently, monthly DPPM data was provided to suppliersconferences.

For major issues, the supplier needs to provide up to five failed samples for fault analysis.

In addition, every quarter, all parties meet at CM factory to review DPPM and defects.

This gives the supplier the opportunity to meet with the CM team to learn about assembly operations and parts mobile programs.

The supplier team reviewed the failure analysis data and developed a corrective action plan.

To help the supplier team find the root cause of the defect, specific information is provided instead of the general DPPM bar chart.

The DPPM data is broken down into the first three defects and the first three parts numbers that have problems, enabling the supplier to first \"root cause\" major problems and minimize their impact on production

An example is shown in Figures 6 and 7.

Conflict Resolution CM\'s differences in operations, part management, refund systems, and language did lead to a conflict about waste charges.

In these cases, the OEM must intervene and ensure a fair resolution of the refund.

To ensure the correct root cause is determined, the fault analysis is evaluated.

If it is a supplier manufacturing problem, a fee is charged to the supplier.

If it\'s a process

Defects such as uncontrollable rework are induced and CM charges are charged.

If both parties contribute, the cost is separate.

The labor force at the CM factory is mainly a very young group with not much experience or training time.

Proper monitoring of training levels is important for good yield and product reliability.

This is also essential because of the departure of employees.

All process changes and engineering change orders should be strictly controlled (ECOs)

Manufacturing change order (MCOs), etc. OEM-

Led training courses in product processing, testing, storage and inspection have also increased production.

Conclusion outsourcing assembly operation makes the original equipment manufacturers have high

The development direction of large-scale database system and enterprise.

However, it also brings us many new challenges, such as cultural differences, communication barriers and skill levels. S.

PCB manufacturing.

Clear, coordinated communication, documentation, patience and teamwork between vendors and CMs are just a few ways to ensure success. REFERENCES (1)

Microvias for low cost, high density interconnect. John H. Lau,S. W. Ricky Lee. (2)

Progress of the Aliv substrate. Daizo A. , Yoshihiro T. ,Tadashi N. , Fumio E. (3)IPC A-610 Rev D--

Acceptability of electronic components. (4)IPC 7095--

Design and assembly process implementation of BGAs. (5)IPC 9701--

Performance test methods and quality requirements for surface mount welding accessories. (6)

SMT \"control and stability of lead-free reflow \". R. Burke, Sept. 2006, Vol. 20, No. 9, pp. 24-26, 28. MUMTAZ Y.

BORA is the chief quality engineer at Kyocera Wireless.

And can reach mbora @ Kyocerawire less. com.

Custom message