Printed Circuit Board Assembly – The comprehensive Guide!(2022)

As a PCB buyer, you may be wondering what the assembly process entails.

Where can you find them? How much do they cost?

This comprehensive guide will answer all your questions and help you decide on the printed circuit board assembly. Let's start reading!

What is Printed Circuit Board Assembly?

In PCBA, electronic components are assembled on a printed circuit board (PCB). We'll talk about various methods in this guide.

The main purpose of PCBA is to connect all of the components of the PCB electrically. Printed circuit board assemblies can be divided into three categories:

Rigid PCBs

Rigid PCBs are the most common type of PCBs. They are made up of one or more layers of tough material, such as fiberglass, which supports the electronic components. Rigid PCBs are usually used in devices that require high reliability, such as computers and telecommunications equipment.

A rigid PCB's main advantage is its high level of reliability. They also tend to be less expensive than other types of PCBs and can be manufactured in large quantities.

However, they are not as flexible as different types of PCBs and can be challenging to work with.

Flexible PCBs

PCBs with adaptable elements are additionally normally referred to as "flex circuits." They can be manufactured using the same types of materials used for rigid PCBs but are made with a polyimide substrate instead.

Flexible PCBs are more flexible than rigid PCBs and have higher durability, making them ideal for use in highly mobile equipment. They can be bent, wrapped around objects, or attached to moving parts without deteriorating.

Rigid-Flex PCBs

An inflexible flex PCB is the third sort of printed circuit board gathering. A rigid-flex PCB has a rigid core with copper traces attached to one side that's surrounded by a protective layer of flexible substrate material such as Kapton or Teflon.

It has all the advantages of both rigid and flexible PCBs, making it an excellent choice when you need a combination of high performance and flexibility. As mentioned earlier, this guide will mainly focus on surface mount technology to create printed circuit board assemblies.

Which are the various ways to create printed circuit board assemblies?

There are various ways to manufacture Printed Circuit Boards. The three most popular methods are:

Surface Mount Technology

Surface mount technology is the most common way to create printed circuit boards.

Soldering directly on a printed circuit board involves attaching electronic components to its surface.

Since the parts are small, they're easy to install and solder, making this method very efficient and cost-effective.

The main advantage of SMT manufacturing is speed. It has a higher throughput than other PTH technology methods since it's easier to automate and doesn't require any drilling or etching steps.

Surface mount PCBs are manufactured quickly without requiring much labor input. SMT is also less expensive due to its high processing speeds and efficiency. However, there are some disadvantages too:

● The boards need proper I/O connections that allow components like connectors and switches to fit into the board properly – if they don't work correctly, then it can cause manufacturing problems.

● Depending on the type of components used, they'll need to be positioned in a specific way for them to line up correctly.

In the case of faulty components, this can make their removal or replacement difficult.

● The process requires high precision to accurately pick and place electronics components onto the PCB, resulting in higher manufacturing costs.

Plated Through-Hole Technology

Before surface mount technology became widespread, through-hole technology was the only way to assemble printed circuit boards. It involves drilling holes into printed circuits that are then plated with a conductive material such as copper or tin.

After that, each hole is filled with solder powder when passing an electric current through it to melt solder until all the electronic components are soldered into place. Through-hole technology is still widely used in older circuit boards that have been assembled for years.

The main advantage of PTH manufacturing is that it's comparatively less expensive compared to SMT since it doesn't require a pick-and-place machine, and the drilling process is automated at lower costs.

The other advantage is that components don't need to be soldered in a specific position, which allows them to be easily removed or replaced if there are any problems with their installation. However, this method also has its downsides:

● The design of the printed circuit board needs to accommodate leads from electronic components placed on both sides of the board - otherwise, the holes would not line up if placed on one side only.

● Solder paste application is very tricky and needs to be applied within tight tolerances.

● The process requires high-precision milling machines that can drill holes of different depths, making it an expensive proposition.

Electro-Mechanical Assembly

Electro-mechanical assembly involves creating printed circuit boards using a combination of different materials. Electronic components are placed on top of sheets made from flexible polymers or metal alloy with electrodes on their surface.

These sheets are then laminated together with additional layers for rigidity. This method is mainly used in low-volume manufacturing where speed isn't as crucial as cost-effectiveness.

However, the downside to electro-mechanical assembly is that it's not commonly used except in niche applications.

When compared to other methods, the challenges associated with electro-mechanical assembly are higher due to its complexity; which makes it challenging to automate the process and results in increased labor costs

● The sheets need connections across them which can be created using additional layers. The production process is, therefore, more expensive.

● The rigidity of printed circuit boards needs to be enhanced, or else they'll tear apart easily - this requires additional layers that make manufacturing more expensive.

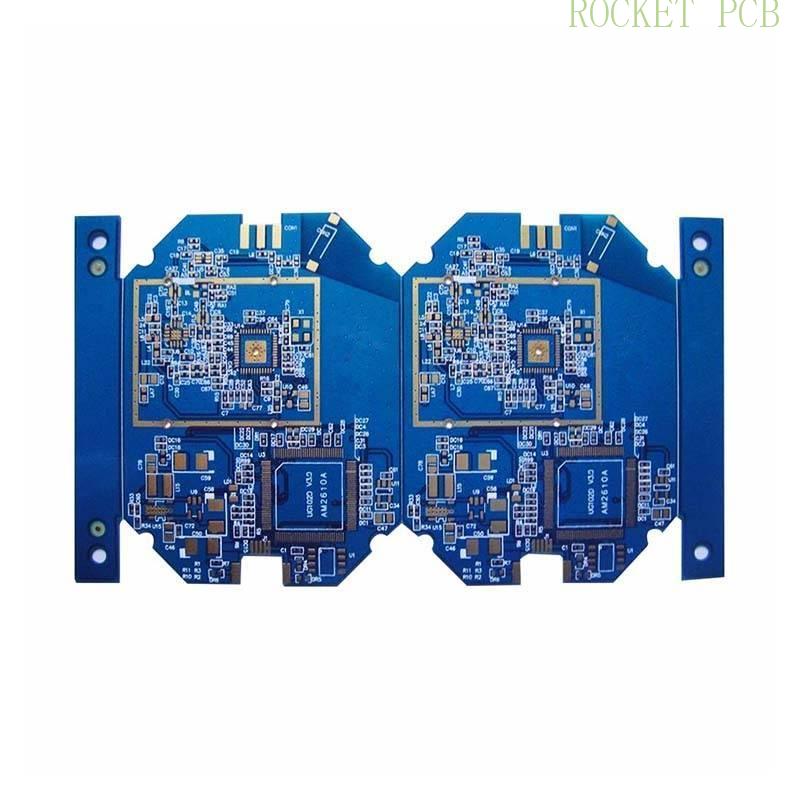

Printed circuit board assembly manufacturer - Rocket PCB

With more than 20 years of experience, Rocket PCB leads the PCBA manufacturing market from the front.

If you are looking for a manufacturer that provides quality at a very affordable cost, then Rocket PCB is the choice.

We have ISO9001, ISO14000, ISO/TS16949 quality and environmental management system certifications besides Rocket PCB uses A-Grade raw material for manufacturing.

Get started with your project now by contacting us.