managing the challenges in rf/microwave designs: because of the growth in mixed-technology products, designers often can\'t use traditional pcb layout tools for rf, and rf tools won\'t work with non-rf circuits. so what\'s the solution?

by:Rocket PCB

2019-08-18

Not long ago, a mobile phone was a mobile phone. The car audio system was just a car audio system.

Today, sound systems and phones are integrated via a Bluetooth RF link to provide built-in functionality

Free features.

A more traditional \"pure\" RF or analog/digital product is an integrated system design with an RF system embedded as a \"on-board system\" and all technologies share a rapidly shrinking board space.

This applies not only to consumer goods, but also to defense and aerospace applications as well as various designs.

Anyone who puts a phone near an office phone or sound system knows that unwanted RF energy can easily be coupled to other systems.

If a phone 3 feet away from another system can disrupt the performance of the system, how do you put the RF circuit on the same board as the other circuits?

First of all, it leads to a whole new set of design requirements.

Design of management RF system-

Including managing EMI/EMC--

Has become a key focus area.

But RF design in a traditional CAD environment can cause serious pain.

At the same time, professional RF design tools cannot be used as the only solution because most RF circuits must coexist with a large number of parts of digital/analog technology.

In addition, the interdependent challenges involved make the design of RF system boards a slow and highly iterative process.

This is unacceptable, and a great focus is on using tools that understand RF features to streamline processes and provide automation in key areas.

There are many separate tasks that need to be managed and each has its own problems.

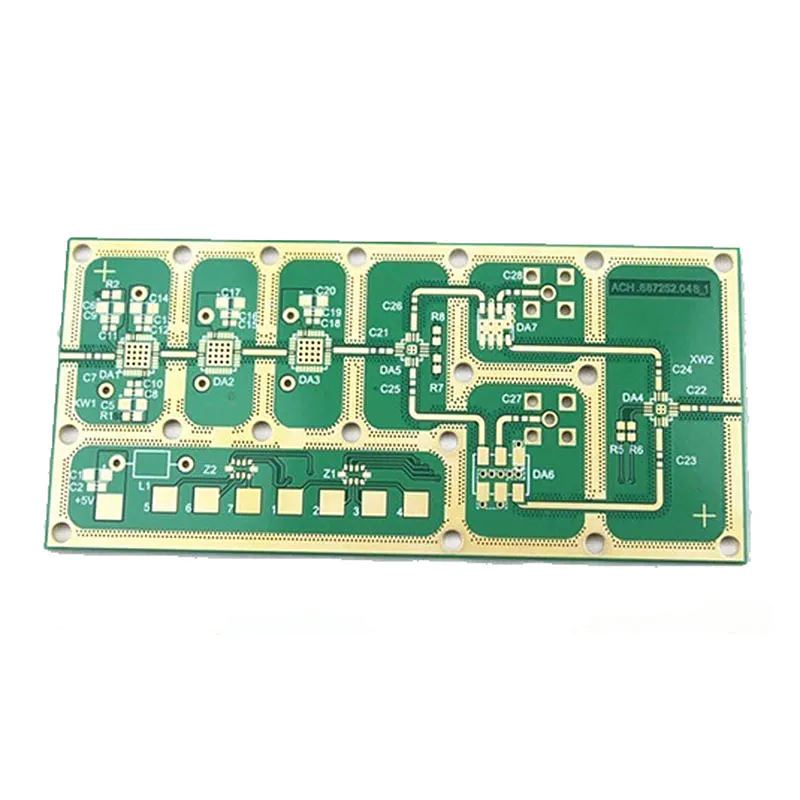

These include: * designing RF circuits and layouts.

* Instantiate RF circuits in schematic and layout.

* Isolate/separate RF from non-RFRF circuitry.

* Manage power and site.

* Analysis of coupling and parasitic.

* Design rules check (DRC).

To facilitate effective RF design, the layout tool function extends to the more common drawing, capture, and alignment functions in mechanical design systems.

Without them, the RF design becomes very slow.

Strict schematic diagram for many types of design

Optimal drive traffic.

But since RF design is a very iterative process, because it is usually designed in the way the layout is on the board

The drive stream is not always the best.

And most importantly, purelylayout-

The drive design is also not feasible as we have largenon-

RF part of the same design.

The solution commonly used is a hybrid schematic/layout-

Non-driven design process

The RF circuit is driven from the schematic and the selected part of the RF circuit is designed as the bottom-

Go up directly in the layout tool.

The basic design is based on the RF interference in place to manage the EMI (EMI)

Become the next major complexity of management.

EMI is a signal energy coupling that is not needed inside the design or between the design and other systems.

After years of high

Speed challenges, many designers are experienced in controlling crosstalk and achieving signal integrity.

The key to their success is a good understanding of how the signal current flows on the board.

When the signal travels down the track, there must be a reverse current to form a closed circuit.

What we have learned is that the return path tries to find the return path with the least impedance. In a low-

Speed Design This is the same as the path with the least resistance or is usually a straight line, but high

The speed signal will have the path of the minimum inductance, which is usually located under the trajectory of the ground plane.

Managing the return path allows the designer to control unwanted coupling and radiation/sensitivity because the amount of radiation is proportional to the Loop area formed by the conductor and its return path.

In addition, if two signals share the return path, the energy of one signal may be coupled to the other in the form of common impedance coupling.

So know where the return path is, make sure the Loop area is minimized, and make sure that the return path is not shared for both critical signals--

At the same time-

Always behind the top.

The speed designer\'s mind.

For RF circuits, the signal is usually returned in the path of the minimum capacitor.

This is a complex factor because it may actually include any conductive surface that is reasonably close, such as a shield box 8 or a metal cabinet.

As a result, the RF function blocks remain compact and the different modules are separated by the grouncompartments, and the RF specialist uses small capacitors to control the RFgrounding and return paths.

Avoid sharing the return path at the input and output levels of the circuit, otherwise it will lead to sufficient feedback coupling (

From higher power output level to sensitive input level)

Causing oscillation.

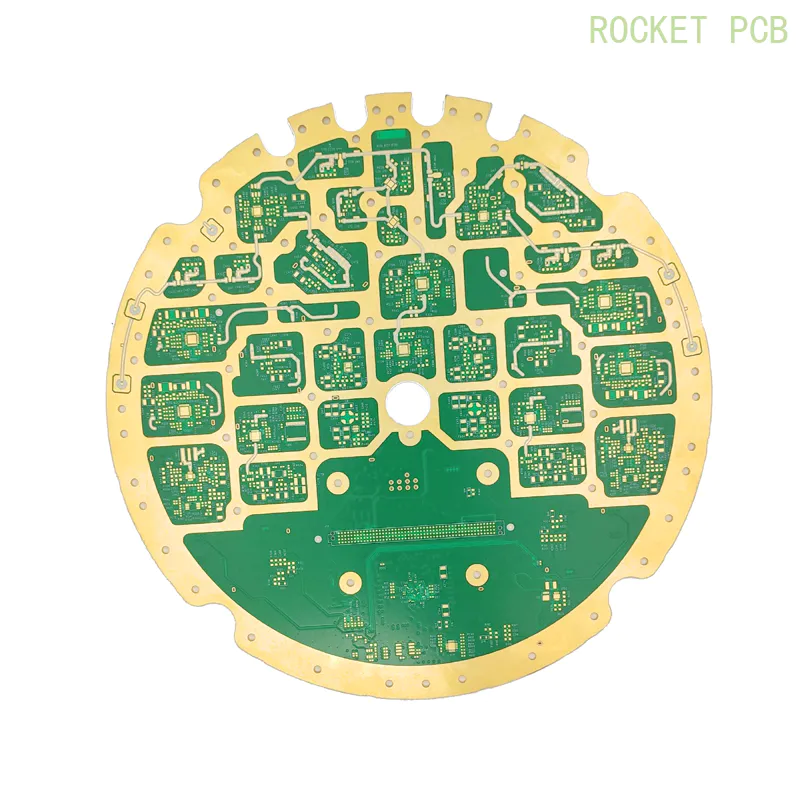

By creating a fence ground with a ground shield and a ground plane, an array is usually generated (

Hiccups with vias)

Or the fence of vias (

Contour stitching)

Connect the plane together.

Why are we doing this?

We often hear vague explanations such as \"it will make the ground better/tighter\" or \"it will prevent RF leakage \".

\"The real reason for these technologies may not be very clear.

There are few studies available, but the references included provide good information.

For all RF designers, they just pepper with vias without knowing why, please read on.

Since we have few separate ground layers, the designer uses vias to pepper the ground area and stitch the edge of the ground area with vias to avoid coupling.

This coupling is due to the fact that the parallel ground plane is excited to so-

Called parallel plate mode, let the signal spread between two planes.

Vias shortened the aircraft together, preventing this mode of transmission on the ground. (1)

Behavior through the fence at very high frequencies, band-pass filters and-to-

The pass pole is controlled by spacing, thus reducing the frequency of the filter. (2)Hence thevia-to-

It is very important to pass the spacing.

The center frequency of the pass band filter is shown in Figure 1: the pass band diameter, the pass band spacing and the function of the dielectric material. (1)([epsilon]

R is the relative dielectric constant of the dielectric material;

Speed of light. )[

Figure 1 slightly]

The center frequency is not the same as the available upper limit.

The space surrounded by four holes is a cavity that resonates at about 0.

65 times the center frequency, we have to keep the RF frequency outside of that area. (1)

In other words, how we insert vias, their pitchand diameters have a great impact on their effectiveness in designing to prevent unwanted coupling.

This causes the ground channel to be inserted into the layout.

Manually insert thousands of ground channels and move them only when the design changes, which is not a viable solution.

On the other hand, this is exactly the purpose of EDA tools: to provide design automation.

Use routines that can track objects and automatically insert multiple rows through fences to understand the boundaries of ground filling and cover their surfaces with the ground

The time allocated to vias is amazing.

By identifying the resonance effect from the ground vias, one can have the tool apply a random variance to the via pattern to avoid all-

The cavity formed resonates at the same frequency.

Figure 2 shows contour stitching and surface by applying pepper with random variance.

Although these holes also form cavities, the size of the cavity is randomly different, and there are different resonance requirements for each small part of the plane. [

Figure 2:

We have controlled the circuit at this point, but there is still a key part missing: power supply.

In the past, the RF compartment was a closed metal cabinet connected to the ground.

Every signal and power source that enters or leaves such a compartment passes through one

Through the capacitor, it is basically a conductor with a coaxial capacitor that is grounded to capture any RF that is trying to escape.

In order to further limit the RF leakage, the RF choke is usually connected in series in the form of a coil, equivalent to the wavelength of the wire.

Needless to say, this is a very expensive way to build;

Today\'s integrated compartment is more practical.

But now we can\'t use feed.

Through the capacitor, the almost perfect low inductance decoupling is theoretically provided, and we need to decoupling the interconnect more carefully to prevent RF leakage

Frequency line in design.

With the RF part designed on a hybrid technology board, the ability to analyze non-

The RF structure in the design has a negative impact on the RF structure and vice versa.

The TheRF circuit may or may not come from RF design and simulation tools.

But in any case, it is now necessary to define the area around the RF circuit, including the surrounding non-

Send the entire area to the RF analysis tool for detailed analysis.

As a result, the demand for integration between layout tools and analysis tools has increased dramatically.

Use the analysis tool link to save model and parameter data through tool loop

Tripand still allows non-inclusion

RF engineers can verify the design without using a very slow manual modeling process.

Why is DRC a naughty word in RF design?

In many ways, RF design using traditional PCB layout tools becomes very painful.

If the design contains only a little RF, a skilled RF designer will manually check the layout to make sure everything is OK.

But today\'s RF design has not only a very complex and large RF part, but also a large number of analog and digital circuits.

We can safely say that in RFworld, the behavior of the signal is not-so-high-

Frequency World: using RF, resonance and standing waves can occur at signal wavelengths related to the length of the conductor on the board.

This fact is used to generate passive RF components of metal patterns on the circuit board.

These metal patterns are connected to each other, usually to the ground to form an RF circuit.

For a classic analog digital design system it looks like a huge shortcircuit.

To make matters worse, as a large number of nets are short-circuited to the ground, it is common that the remaining nets cannot be properly covered, leaving us with a complex design that cannot be checked.

On the other hand, we cannot pretend that the RF element is not conductive because we need the DRC to verify that the RF element is also properly connected to each other.

The solution is to use a design system that can distinguish between RF and non-RF structures

RFstructures and provide DRCs that make sense in each discipline.

Following this pattern, every time you make a design successfully, the next one will be worse, and we can rely on more integration, more complex RF modules and higher frequencies make it more difficult to control the return path and coupling.

There is no doubt that the future of RE/microwave design will be harsh, but exciting. REFERENCES (1. )

The House of Dajin Xiye and Xiu-

Harbin, parallel plate die suppression byGround Via with simple design formulaHoles in Multi-

Layered packaging of Mitsubishi Electric

On May 2001, kam Kamakura, Kanagawa, Japan. (2. )

Thorsten Tischler, Matthias Rudolf, Andreas Kilk, andWolfgang Heinrich, \"MultilayerPackaging through the grounding of the array--

Frequency limits and design rules, FerdinandBraun-

Berlin Fur Institute, Germany.

Each VIKLUND is the marketing manager of Mentor Graphics.

Responsible for RF, embedded components, and advanced packaging solutions.

Viklund can play per_viklund @ tutor. com.

Today, sound systems and phones are integrated via a Bluetooth RF link to provide built-in functionality

Free features.

A more traditional \"pure\" RF or analog/digital product is an integrated system design with an RF system embedded as a \"on-board system\" and all technologies share a rapidly shrinking board space.

This applies not only to consumer goods, but also to defense and aerospace applications as well as various designs.

Anyone who puts a phone near an office phone or sound system knows that unwanted RF energy can easily be coupled to other systems.

If a phone 3 feet away from another system can disrupt the performance of the system, how do you put the RF circuit on the same board as the other circuits?

First of all, it leads to a whole new set of design requirements.

Design of management RF system-

Including managing EMI/EMC--

Has become a key focus area.

But RF design in a traditional CAD environment can cause serious pain.

At the same time, professional RF design tools cannot be used as the only solution because most RF circuits must coexist with a large number of parts of digital/analog technology.

In addition, the interdependent challenges involved make the design of RF system boards a slow and highly iterative process.

This is unacceptable, and a great focus is on using tools that understand RF features to streamline processes and provide automation in key areas.

There are many separate tasks that need to be managed and each has its own problems.

These include: * designing RF circuits and layouts.

* Instantiate RF circuits in schematic and layout.

* Isolate/separate RF from non-RFRF circuitry.

* Manage power and site.

* Analysis of coupling and parasitic.

* Design rules check (DRC).

To facilitate effective RF design, the layout tool function extends to the more common drawing, capture, and alignment functions in mechanical design systems.

Without them, the RF design becomes very slow.

Strict schematic diagram for many types of design

Optimal drive traffic.

But since RF design is a very iterative process, because it is usually designed in the way the layout is on the board

The drive stream is not always the best.

And most importantly, purelylayout-

The drive design is also not feasible as we have largenon-

RF part of the same design.

The solution commonly used is a hybrid schematic/layout-

Non-driven design process

The RF circuit is driven from the schematic and the selected part of the RF circuit is designed as the bottom-

Go up directly in the layout tool.

The basic design is based on the RF interference in place to manage the EMI (EMI)

Become the next major complexity of management.

EMI is a signal energy coupling that is not needed inside the design or between the design and other systems.

After years of high

Speed challenges, many designers are experienced in controlling crosstalk and achieving signal integrity.

The key to their success is a good understanding of how the signal current flows on the board.

When the signal travels down the track, there must be a reverse current to form a closed circuit.

What we have learned is that the return path tries to find the return path with the least impedance. In a low-

Speed Design This is the same as the path with the least resistance or is usually a straight line, but high

The speed signal will have the path of the minimum inductance, which is usually located under the trajectory of the ground plane.

Managing the return path allows the designer to control unwanted coupling and radiation/sensitivity because the amount of radiation is proportional to the Loop area formed by the conductor and its return path.

In addition, if two signals share the return path, the energy of one signal may be coupled to the other in the form of common impedance coupling.

So know where the return path is, make sure the Loop area is minimized, and make sure that the return path is not shared for both critical signals--

At the same time-

Always behind the top.

The speed designer\'s mind.

For RF circuits, the signal is usually returned in the path of the minimum capacitor.

This is a complex factor because it may actually include any conductive surface that is reasonably close, such as a shield box 8 or a metal cabinet.

As a result, the RF function blocks remain compact and the different modules are separated by the grouncompartments, and the RF specialist uses small capacitors to control the RFgrounding and return paths.

Avoid sharing the return path at the input and output levels of the circuit, otherwise it will lead to sufficient feedback coupling (

From higher power output level to sensitive input level)

Causing oscillation.

By creating a fence ground with a ground shield and a ground plane, an array is usually generated (

Hiccups with vias)

Or the fence of vias (

Contour stitching)

Connect the plane together.

Why are we doing this?

We often hear vague explanations such as \"it will make the ground better/tighter\" or \"it will prevent RF leakage \".

\"The real reason for these technologies may not be very clear.

There are few studies available, but the references included provide good information.

For all RF designers, they just pepper with vias without knowing why, please read on.

Since we have few separate ground layers, the designer uses vias to pepper the ground area and stitch the edge of the ground area with vias to avoid coupling.

This coupling is due to the fact that the parallel ground plane is excited to so-

Called parallel plate mode, let the signal spread between two planes.

Vias shortened the aircraft together, preventing this mode of transmission on the ground. (1)

Behavior through the fence at very high frequencies, band-pass filters and-to-

The pass pole is controlled by spacing, thus reducing the frequency of the filter. (2)Hence thevia-to-

It is very important to pass the spacing.

The center frequency of the pass band filter is shown in Figure 1: the pass band diameter, the pass band spacing and the function of the dielectric material. (1)([epsilon]

R is the relative dielectric constant of the dielectric material;

Speed of light. )[

Figure 1 slightly]

The center frequency is not the same as the available upper limit.

The space surrounded by four holes is a cavity that resonates at about 0.

65 times the center frequency, we have to keep the RF frequency outside of that area. (1)

In other words, how we insert vias, their pitchand diameters have a great impact on their effectiveness in designing to prevent unwanted coupling.

This causes the ground channel to be inserted into the layout.

Manually insert thousands of ground channels and move them only when the design changes, which is not a viable solution.

On the other hand, this is exactly the purpose of EDA tools: to provide design automation.

Use routines that can track objects and automatically insert multiple rows through fences to understand the boundaries of ground filling and cover their surfaces with the ground

The time allocated to vias is amazing.

By identifying the resonance effect from the ground vias, one can have the tool apply a random variance to the via pattern to avoid all-

The cavity formed resonates at the same frequency.

Figure 2 shows contour stitching and surface by applying pepper with random variance.

Although these holes also form cavities, the size of the cavity is randomly different, and there are different resonance requirements for each small part of the plane. [

Figure 2:

We have controlled the circuit at this point, but there is still a key part missing: power supply.

In the past, the RF compartment was a closed metal cabinet connected to the ground.

Every signal and power source that enters or leaves such a compartment passes through one

Through the capacitor, it is basically a conductor with a coaxial capacitor that is grounded to capture any RF that is trying to escape.

In order to further limit the RF leakage, the RF choke is usually connected in series in the form of a coil, equivalent to the wavelength of the wire.

Needless to say, this is a very expensive way to build;

Today\'s integrated compartment is more practical.

But now we can\'t use feed.

Through the capacitor, the almost perfect low inductance decoupling is theoretically provided, and we need to decoupling the interconnect more carefully to prevent RF leakage

Frequency line in design.

With the RF part designed on a hybrid technology board, the ability to analyze non-

The RF structure in the design has a negative impact on the RF structure and vice versa.

The TheRF circuit may or may not come from RF design and simulation tools.

But in any case, it is now necessary to define the area around the RF circuit, including the surrounding non-

Send the entire area to the RF analysis tool for detailed analysis.

As a result, the demand for integration between layout tools and analysis tools has increased dramatically.

Use the analysis tool link to save model and parameter data through tool loop

Tripand still allows non-inclusion

RF engineers can verify the design without using a very slow manual modeling process.

Why is DRC a naughty word in RF design?

In many ways, RF design using traditional PCB layout tools becomes very painful.

If the design contains only a little RF, a skilled RF designer will manually check the layout to make sure everything is OK.

But today\'s RF design has not only a very complex and large RF part, but also a large number of analog and digital circuits.

We can safely say that in RFworld, the behavior of the signal is not-so-high-

Frequency World: using RF, resonance and standing waves can occur at signal wavelengths related to the length of the conductor on the board.

This fact is used to generate passive RF components of metal patterns on the circuit board.

These metal patterns are connected to each other, usually to the ground to form an RF circuit.

For a classic analog digital design system it looks like a huge shortcircuit.

To make matters worse, as a large number of nets are short-circuited to the ground, it is common that the remaining nets cannot be properly covered, leaving us with a complex design that cannot be checked.

On the other hand, we cannot pretend that the RF element is not conductive because we need the DRC to verify that the RF element is also properly connected to each other.

The solution is to use a design system that can distinguish between RF and non-RF structures

RFstructures and provide DRCs that make sense in each discipline.

Following this pattern, every time you make a design successfully, the next one will be worse, and we can rely on more integration, more complex RF modules and higher frequencies make it more difficult to control the return path and coupling.

There is no doubt that the future of RE/microwave design will be harsh, but exciting. REFERENCES (1. )

The House of Dajin Xiye and Xiu-

Harbin, parallel plate die suppression byGround Via with simple design formulaHoles in Multi-

Layered packaging of Mitsubishi Electric

On May 2001, kam Kamakura, Kanagawa, Japan. (2. )

Thorsten Tischler, Matthias Rudolf, Andreas Kilk, andWolfgang Heinrich, \"MultilayerPackaging through the grounding of the array--

Frequency limits and design rules, FerdinandBraun-

Berlin Fur Institute, Germany.

Each VIKLUND is the marketing manager of Mentor Graphics.

Responsible for RF, embedded components, and advanced packaging solutions.

Viklund can play per_viklund @ tutor. com.

Custom message