Make Your Electronic Device, Exactly As You Envisaged

by:Rocket PCB

2020-04-27

A lot of people consider themselves creative when it comes to electronic devices. In fact, given the current reach of mobile phones and MP3 players, practically every second person has what he or she thinks is a great idea for a phone or tablet. There are newer and newer touch screen models coming out every day, with all leading companies jostling each other for market share. In this kind of scenario, what do you do if you have come up with what you believe is a great idea for a mobile phone?

The simplest thing to do would be to consult a company that specializes in EDS and EMS. These are two fields that, though related, are very different in terms of function and end result. EDS is an acronym for Electronic Design services. A company that specializes in EDS will have all the technical talent and support that is necessary to help make your dream a reality. There are a number of people, each adept at a certain type of science who will work together as a team to see your product through to the very end.

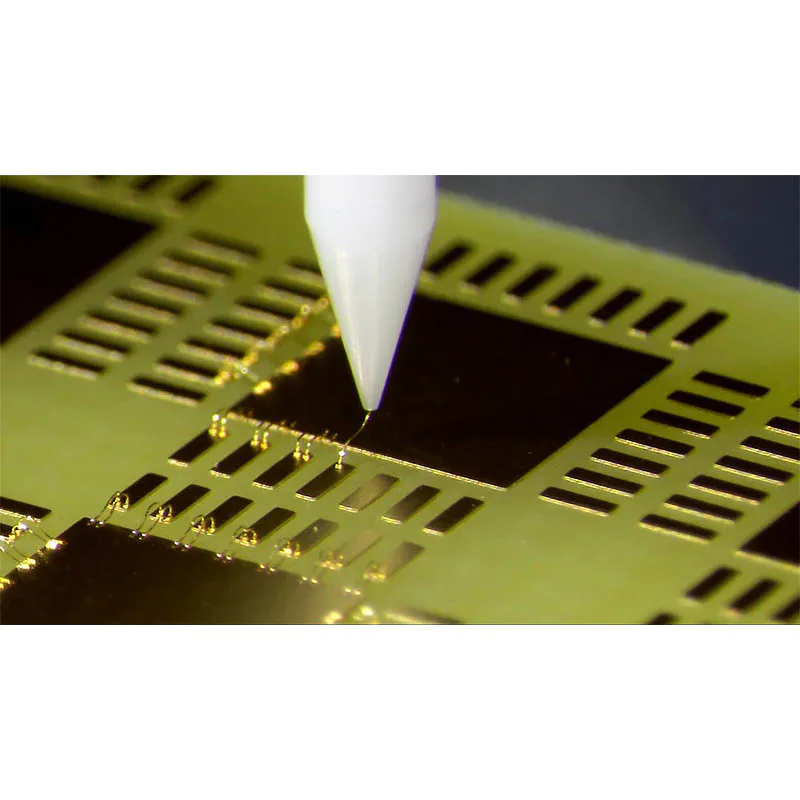

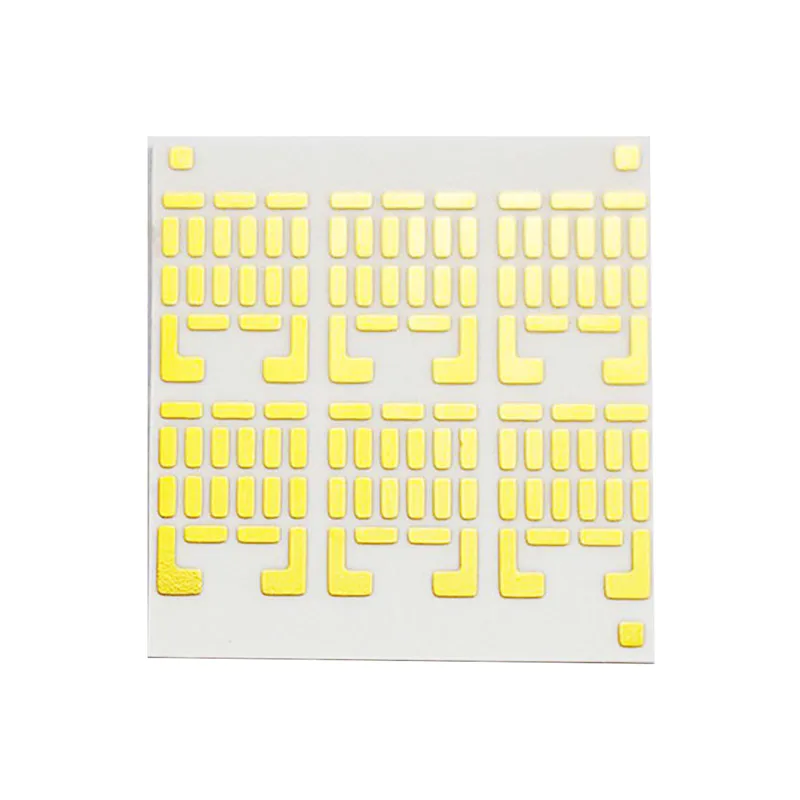

Electronic Design services can broadly be broken up into four stages: System Architecture, Design, Prototype and Production. System Architecture is the first phase, wherein various parameters like the specifications you want for your device (memory, speed of operation, size etc.) will be determined. Other factors like the selection of components and software specification are also decided. In the next stage, namely Design, a layout is drawn with a fully schematic arrangement of your device. Once this is satisfactory, the next stage commences. In the Prototype phase, a working model of the device is made and the board is fabricated and checked for errors. These errors are then corrected (debugging in IT parlance) and then the final step, i.e. Production for market, is put into place.

EMS is an acronym for Electronic Manufacturing services. This means that the company has a team of members that will make the entire manufacturing process happen right from the start. This includes procedures like PCB assembly, PCB testing and turnkey manufacturing. There are a number of processes by which the manufacturing is effected, namely injection molding, extrusion and other such mechanical processes. The company will ensure quality and efficiency from first to last.

Apart from EMS and EDS, there are a number of intangible advantages in enlisting the help of a company for manufacturing, rather than attempting it as an individual. For one, getting the help of a supplier in China will be very difficult. This is because suppliers tend to think twice when it comes to giving parts to an individual. On the other hand if it is carried out by a company, the transaction will be in bulk and hence there is no reluctance. Also, a company will find it much easier to develop a good business relationship with a reliable supplier, to ensure a continuous inflow of the necessary parts. With the right company, that device which you have in your head can become a tangible product.

Custom message