know the reason and application of prototype pcb assembly

by:Rocket PCB

2019-08-31

Recently, there has been a significant surge in the use and manufacture of electronic instruments.

By the way, the use of printed circuit boards is now common in almost all types of devices.

As a paying customer, it is your privilege to choose the product that will give you the best output and the lowest cost.

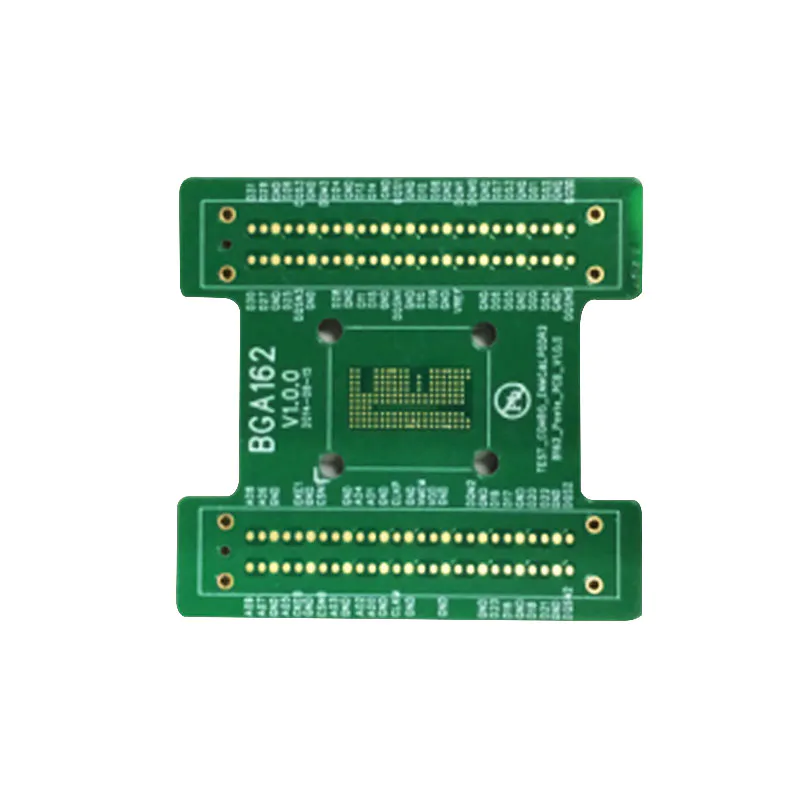

The pcb manufacturing company of your choice must be proficient in designing and developing special customized pcb according to customer\'s requirements, as well as general purpose and good pcbknown ones.

So if your project requires a pcb or any related modules, please contact the top companies in the business.

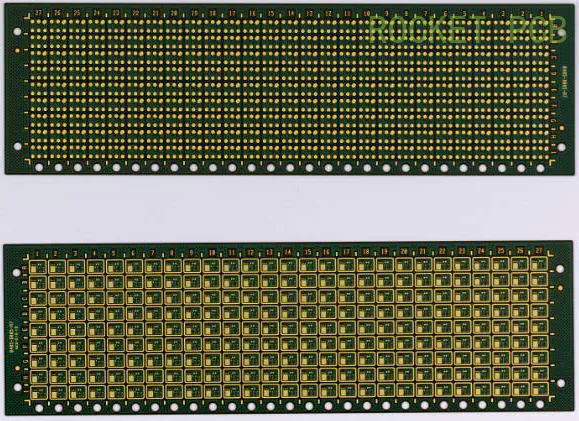

The purpose of the prototype circuit is usually that the manufacturing materials of the pcb are developed using a chemical that gives the pcb an indomitable fixed structure.

When the profile covered by your machine is not straight, you need the PCB to arrange yourself according to the space, and then, this is your way to make a prototype PCB assembly for your instrument.

In addition, when the functional requirements of the related equipment need more than the general equipment, the best choice is to use a special PCB.

Discussing with the company you choose will be a prudent job.

Determining the best aspects of the company that manufactures state-of-the-art mechanical products will be proficient in producing dynamic pcb according to the requirements specified by the buyer.

Make sure the top position-

Quality products within the economic price range must be purchased from the best quality products

Known prototype PCB assembly manufacturer according to customer specifications.

The perception that needs to be used for the highest performance can be grouped; 1.

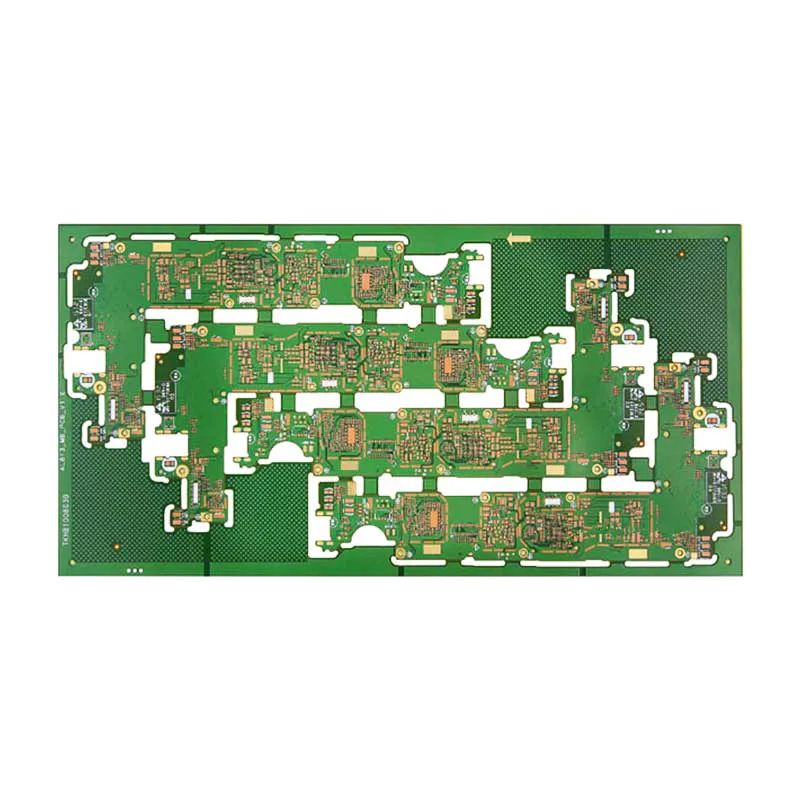

Companies with the best mobility restrictions will always ensure the position of the necessary and components that need to be placed on the board.

It must be remembered that the appropriate spacing must always be maintained to ensure the best functionality of the PCB.

The integrated circuit should be placed within the allowed distance.

After the manufacturing is completed, it is best to store the circuit board so that QC inspection can be carried out later. 2.

The correct balance of the PCB assembly in order to obtain consistent welding, the parts must be arranged in the same way as each other.

In addition, the most skilled companies should allow the least intersection between conductive paths to occur in order to make wiring easier.

In order to get the best results, it is best to connect the edge parts first and start the manufacturing process.

In addition, the intersection of the connection must be kept near zero to reduce the probability of a short circuit, and the live component must remain in the same direction as the PCB.

Call for action is best to interact with the most talented industry to meet all your PCB needs.

Use their facilities to get help at the top

PCB and similar products. Read more-

By the way, the use of printed circuit boards is now common in almost all types of devices.

As a paying customer, it is your privilege to choose the product that will give you the best output and the lowest cost.

The pcb manufacturing company of your choice must be proficient in designing and developing special customized pcb according to customer\'s requirements, as well as general purpose and good pcbknown ones.

So if your project requires a pcb or any related modules, please contact the top companies in the business.

The purpose of the prototype circuit is usually that the manufacturing materials of the pcb are developed using a chemical that gives the pcb an indomitable fixed structure.

When the profile covered by your machine is not straight, you need the PCB to arrange yourself according to the space, and then, this is your way to make a prototype PCB assembly for your instrument.

In addition, when the functional requirements of the related equipment need more than the general equipment, the best choice is to use a special PCB.

Discussing with the company you choose will be a prudent job.

Determining the best aspects of the company that manufactures state-of-the-art mechanical products will be proficient in producing dynamic pcb according to the requirements specified by the buyer.

Make sure the top position-

Quality products within the economic price range must be purchased from the best quality products

Known prototype PCB assembly manufacturer according to customer specifications.

The perception that needs to be used for the highest performance can be grouped; 1.

Companies with the best mobility restrictions will always ensure the position of the necessary and components that need to be placed on the board.

It must be remembered that the appropriate spacing must always be maintained to ensure the best functionality of the PCB.

The integrated circuit should be placed within the allowed distance.

After the manufacturing is completed, it is best to store the circuit board so that QC inspection can be carried out later. 2.

The correct balance of the PCB assembly in order to obtain consistent welding, the parts must be arranged in the same way as each other.

In addition, the most skilled companies should allow the least intersection between conductive paths to occur in order to make wiring easier.

In order to get the best results, it is best to connect the edge parts first and start the manufacturing process.

In addition, the intersection of the connection must be kept near zero to reduce the probability of a short circuit, and the live component must remain in the same direction as the PCB.

Call for action is best to interact with the most talented industry to meet all your PCB needs.

Use their facilities to get help at the top

PCB and similar products. Read more-

Custom message