Introduction to single-ended impedance control on PCB circuit boards 50 ohm

by:Rocket PCB

2020-05-28

Many engineers at the time of PCB circuit board design, for people new to PCB impedance will have the question, why common single-ended walk line within the circuit board is the default requirements according to 50 ohm to control rather than 40 ohms or 60 ohms?

This is a seemingly simple, but not good answer.

Before writing this article, we also find a lot of information on the impedance of the circuit board, is one of the most famous HowardJohnson, PhD reply about this problem, believe that a lot of people have seen.

Why not answer?

Signal integrity problems itself is a question of trade-offs, so in the industry's most famous sentence is: the & # 8221;

Itdepends…

”

This is no standard answer, has seen and heard as well as a problem.

Today is Mr High-speed integrated various answer to simple summary on this issue, in this is also a topic, hope more people can be from the perspective of their respective summed up the more related factors.

A, 50 ohm is has certain historical origin, it from the standard cable, we all know that a large part of modern electronic technology is from the army, the military to civilian use, slowly in the early stages of the application of microwave, the second world war, the selection of impedance depends entirely on the need of using.

With the progress of technology, it is necessary to give the impedance standards, in order to strike a balance on the efficiency and convenience.

In the United States, using catheter is most by the existing rod rod and the pipe connection, 51.

5 ohms is common, but see and use the adapter/converter is 50 ohm to 51.

5 ohm.

For joint army and navy to solve these problems, founded a group called JAN, the later DESC, by MIL special development, finally chose 50 ohm after comprehensive consideration, and special catheter were made, and thus into various cable standard.

European standard is 60 ohms, not long after, as Hewlett -

Packard that are under the influence of the dominant company in the industry, the people of Europe were changed, so 50 ohm inherited from the eventually become a standard in the industry, has become established, and a variety of cable connection of PCB, for the sake of impedance matching, finally also is according to 50 ohm impedance standards requirements.

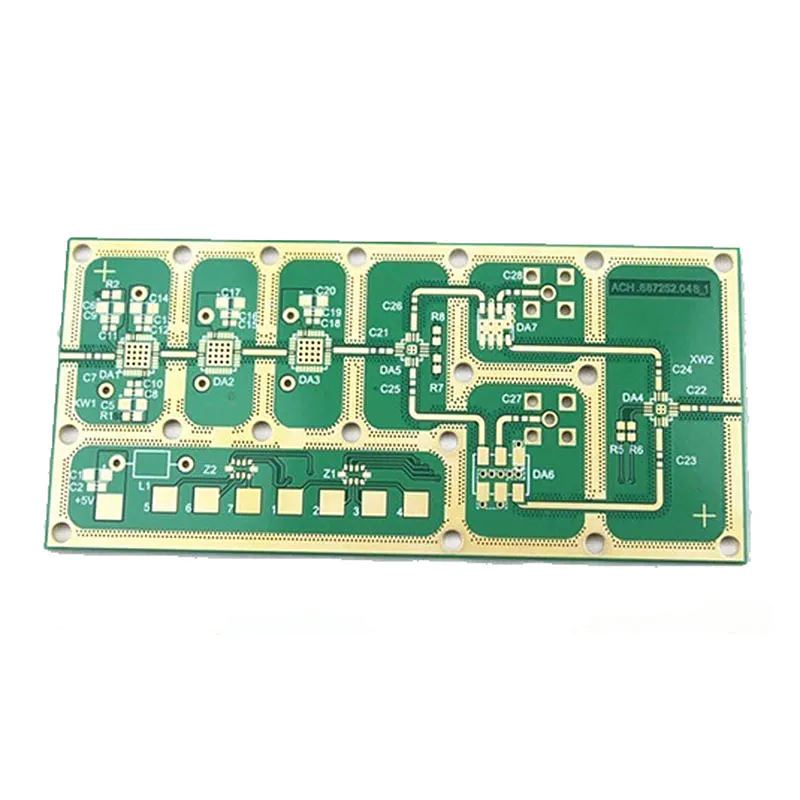

Second, from the perspective of PCB production can be realized, 50 ohm to implement more convenient.

From the previous formula of impedance, low PCB circuit board impedance need wide line width and thin medium (

Or the larger dielectric constant)

For the current density board is difficult to satisfy the space;

High impedance and a narrow line width and thick medium (

Or a smaller dielectric constant)

To the detriment of EMI and crosstalk suppression, at the same time for a multilayer and in terms of production and processing of reliability will be poor;

And 50 ohm materials under the environment of commonly used in ordinary line width, and the medium thickness (

4mil-

6mil)

Comply with the design requirements (

The diagram below a impedance calculation)

, and convenient processing, slowly become a default choice it is not surprising.

PCB circuit boards impedance calculation of three, from the perspective of loss, according to the basic physics of 50 ohm impedance skin effect minimum loss (

Reply from HowardJohnson, PhD)

。

Usually the skin effect of the cable loss (L

In decibels unit)

And the total skin effect resistance R (

Per unit length)

Divided by the characteristic impedance is proportional Z0.

The total skin effect resistance R is shielding layer and the conductor resistance is the sum of the middle.

Shielding layer of the skin effect of resistance in high frequency, and it is inversely proportional to the diameter of d2.

The coaxial cable of the inner conductor skin effect resistance in high frequency, and he is inversely proportional to the diameter of d1.

A total of series resistance R, and therefore (

1 / d2 + 1 / d1)

Is proportional to the.

Integrated these factors, d2 and given the corresponding isolation material dielectric constant Er, can use the following formula to make skin effect minimum loss.

Formula of circuit boards isolated from constant formula 3 items (

/ 60)

*(

1/d2)

, the effective items (

(

1 + d2 / d1)

/ln(

d2 / d1)

)

To determine the minimum point.

Take a closer look at formula 3 minimum point only controlled by/d1, d2, and Er, and fixed value d2 has nothing to do.

D1 / d2 as the parameter, as L do figure, display/d1, d2 = 3.

In 5911, to obtain the minimum value.

Assume that solid polyethylene dielectric constant of 2.

25日,d2 / d1 = 3。

5911 it is concluded that the characteristic impedance of 51.

One ohm.

Radio engineers for convenient use, long time before, the approximate value of 50 ohm coaxial cable of the as the optimal value.

This proved that the near 50 ohm, L is the smallest.

Finally, from the perspective of the electrical properties of the advantage of 50 ohm is after comprehensive consideration of compromise.

Simply walk from PCB line, the performance of low impedance is better, for a given line width of transmission line, and plane the closer distance, the corresponding EMI shrink, crosstalk will therefore decreases, and at the same time not easily affected by the capacitive load.

But from the perspective of the full path, also need to consider one of the key factors, that is the ability to drive chip, most early don't chip driver PCB circuit board less than 50 ohm impedance transmission lines, and achieving higher impedance of the transmission lines due to the inconvenience, so compromise adopted 50 ohm impedance.

Above all: 50 ohm as the default value of the industry has its inherent advantages, but also after the comprehensive consideration of compromise, but is not to say that they must use 50 ohm impedance, and a lot of times still depends on the matching of interface, such as 75 ohms is still a remote communication standards, some cable and antenna are using 75 ohms, PCB line impedance matching is required at this time.

There are some special drive ability, by improving the chip to reduce the impedance of the transmission line, in order to get a better suppression of EMI and the effect of crosstalk, as most of Intel chip request impedance control in 37 ohms, 42 even lower ohm, go here.

With new and upcoming social commerce technologies, the biggest change for pcb making service marketers will be a shift in focus from branding to lead generation and conversion.

Serving others for customers a better life with pcb making service for employees respect and opportunity.

The key to pcb making service is understanding where there is a problem or need in certain markets and knowing how to solve it.

With new and upcoming social commerce technologies, the biggest change for pcb making service marketers will be a shift in focus from branding to lead generation and conversion.

Serving others for customers a better life with pcb making service for employees respect and opportunity.

The key to pcb making service is understanding where there is a problem or need in certain markets and knowing how to solve it.

Custom message