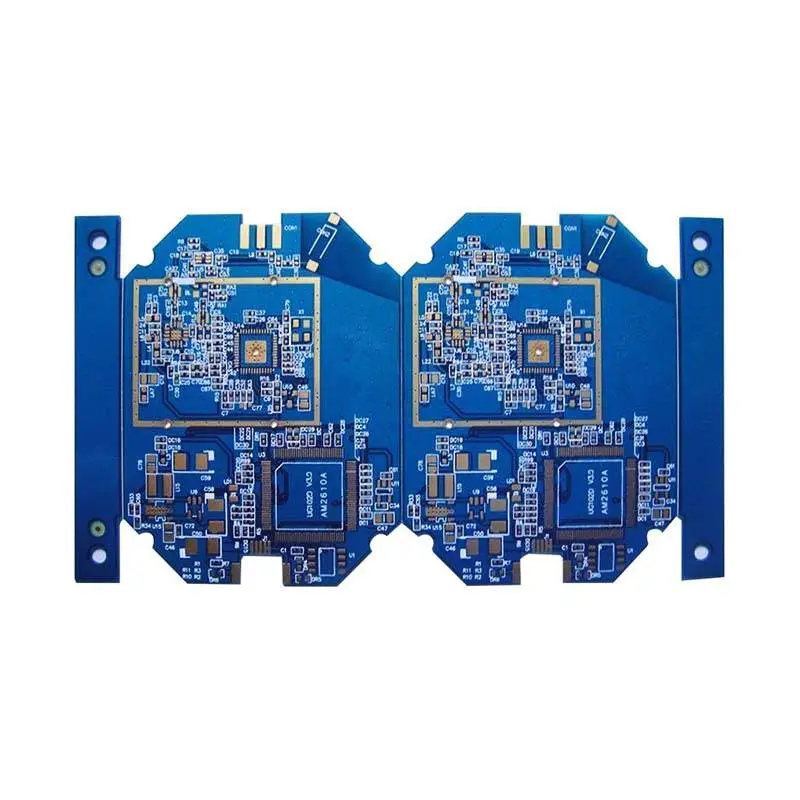

Introduction to circuit boards of several common quality problems

by:Rocket PCB

2020-06-22

For circuit board quality problems generally has a short circuit, open circuit, sparkling green oil, green oil, words red, base material layer, plate bend, welding plate, tin on bad and circuit boards such as open circuit after aging problem.

These common PCB quality problem, the root cause lies in the circuit board factory production process does not pass, backward production equipment, the inferior raw materials selection, management confusion caused by these aspects.

PCB reason one: PCB choose cheap inferior raw materials.

The quality of raw materials is the foundation of circuit board quality, the material of itself does not pass, the circuit can appear bubbles, layered, craze, board become warped, the thickness is not equal.

Now more concealed is some circuit board factory is the mixed material used, part quality goods sheet, is part of the edge material, in order to diluted costs, the hidden trouble is that I don't know which batch.

Due to circuit boards using features is different, some circuit board request is not high, so some edge material use in this performance is the key to the obvious problem, which makes a lot of circuit board factory such practices muddle through, at the same time because of the low price to win the customer's preference.

More encouraged the circuit board factory to continue this adventure.

The long run, if the base material problems lead to finished product quality problems, tend to be costly, and sometimes is irrevocable corporate reputation and brand.

This is a little formal circuit board manufacturers didn't do this.

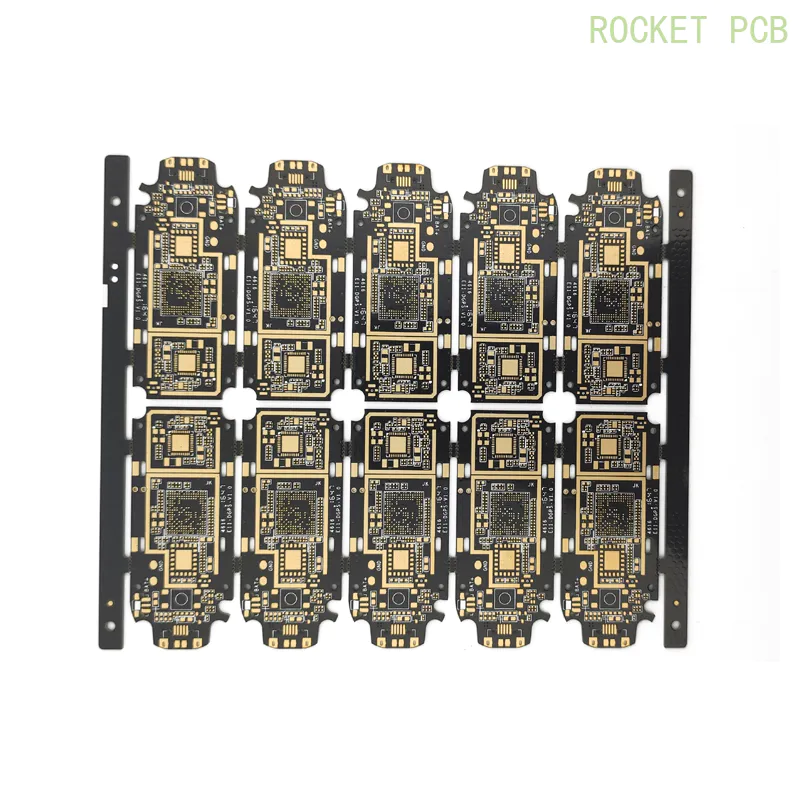

Reason two: circuit board production equipment behind.

Equipment from the hardware to ensure quality, increase spending on equipment, to achieve efficient equipment, stable is basic way of improving the quality of circuit board.

With the progress of science and technology, circuit equipment upgrading more and more fast, more and more advanced equipment, of course the price also is more and more expensive.

This leads to a small circuit board factory are not capable of adding more expensive equipment, resulting in the dependence of the employees.

Now human cost is high, once formed for skilled skilled employees depend on formation, circuit board factory management will greatly increase the difficulty, once appear, mobility, circuit board quality will fluctuate.

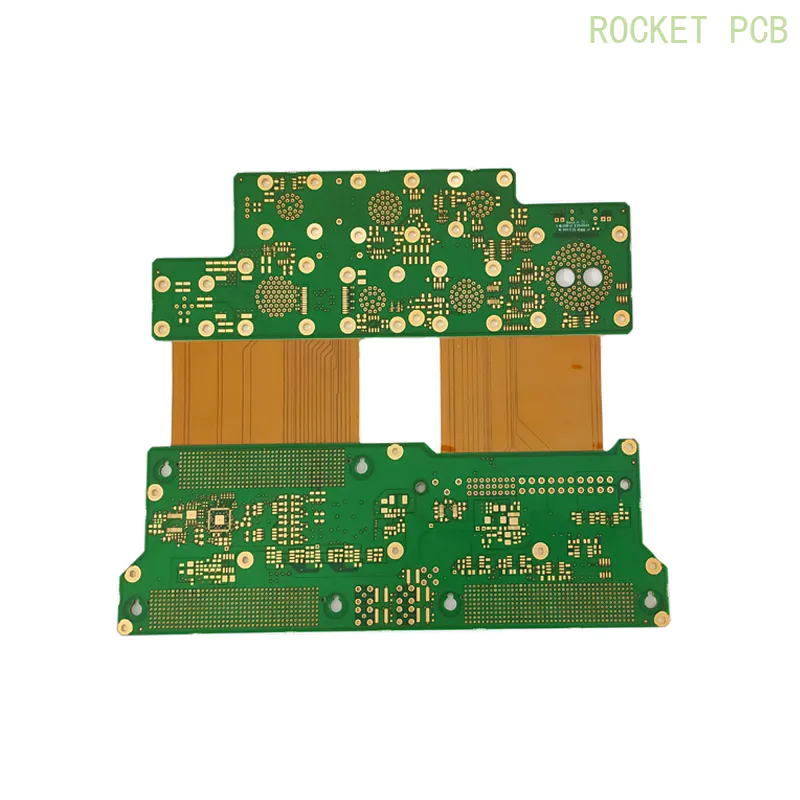

Reason 3: PCB production process does not pass.

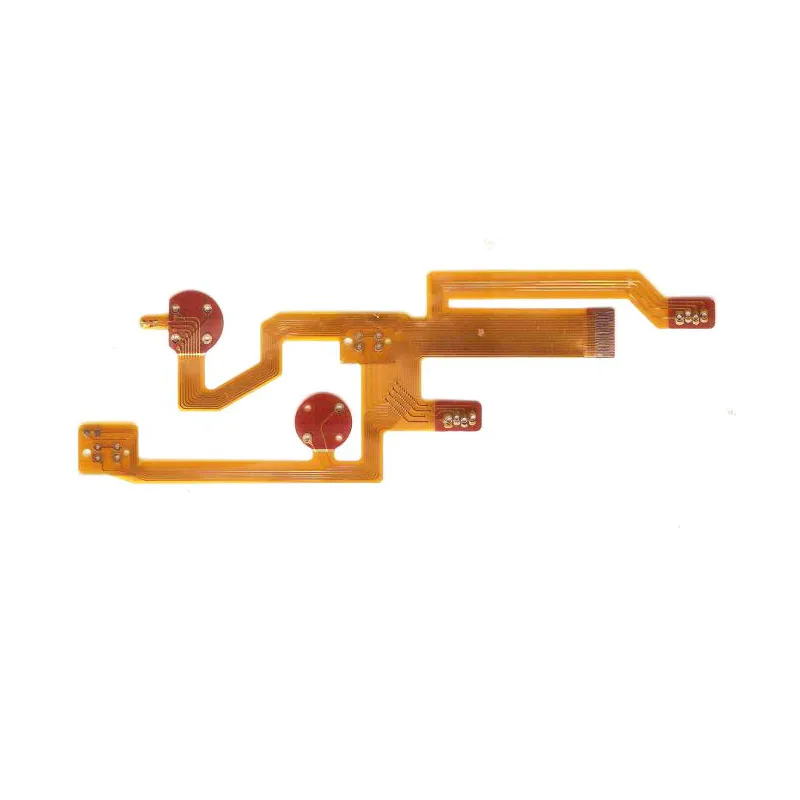

Circuit board production is a high technology content industry, involving electroplating, chemical industry, machinery, and a series of cross subject.

Each working procedure of PCB production must, in accordance with strict production process to implement production, at the same time, each working procedure must be equipped with corresponding detection and laboratory equipment, the process parameters and equipment to ensure the stability of the circuit board quality.

There is no denying the fact that circuit board industry and is a polluting industries, entering the industry's many workers, and even the boss is quite a lot of mid-career, so lead to many small circuit board factory only care about the price, as long as you can hold down costs, on the production process and circuit board quality completely don't care.

Potions concentration in electroplating process is a time change parameters, different types of circuit boards, the plating process of the current size and time are also different, these parameters are together affects the quality of circuit board.

Only strict production process guidance, according to the production process parameters, and laboratory tests, to ensure the quality of production of circuit boards in a steady state.

If it is manufactured by experience, appear quality problem, add potion by feeling, this is a direct result of the quality of the circuit board is always in volatility, customers to use will appear this kind of circuit board repair rate is high, the yield is low, the surface looks PCB procurement cost is reduced, in fact maintenance, repair maintenance cost greatly increase at the same time, the customer brand is affected, it is not economical to long term.

Reason 4: management confusion.

Production process of PCB factory, cycle is long, how to realize the scientific and orderly management, it is a difficult problem at the same time also can reduce the management cost, is well tube, tube to live, too cheap, this need long-term accumulation of PCB manufacturer.

With the progress of science and technology, especially the development of the network, by means of network information technology to the traditional circuit board factory management possible.

A breakthrough in this aspect to form the core competitiveness.

Bad management of factory, circuit board quality will naturally often fluctuation, all sorts of problems emerge in endlessly, appeared again and again.

In conclusion: PCB quality problem is a serious problem, also need PCB factory long-term effort, in the management, good faith, devotion and absorb new technology on the result of the continuous efforts.

Rocket PCB Solution Ltd. specializes in undertaking corporate offers to cater the needs of different companies.

Dazzle your next event with pcb manufacturing services pcb making service and to buy best product, only trust Rocket PCB Solution Ltd..

We utilize our expertise to develop services that add value at each phase of thepcb making service development cycle. We evaluate and implement new strategies in response to changing customer profiles and market conditions.

Rocket PCB Solution Ltd. is an online resource for today's modern woman to live a green, healthy, and happy life. We offer pcb making service, pcb manufacturing services and more! Pls visit our site at Rocket PCB to know more.

Rocket PCB Solution Ltd. specializes in undertaking corporate offers to cater the needs of different companies.

Dazzle your next event with pcb manufacturing services pcb making service and to buy best product, only trust Rocket PCB Solution Ltd..

We utilize our expertise to develop services that add value at each phase of thepcb making service development cycle. We evaluate and implement new strategies in response to changing customer profiles and market conditions.

Rocket PCB Solution Ltd. is an online resource for today's modern woman to live a green, healthy, and happy life. We offer pcb making service, pcb manufacturing services and more! Pls visit our site at Rocket PCB to know more.

Custom message