Introduction of single sided pcb

Single Sided PCB contain only one layer of conductive material and are best suited for low density designs. Single sided PCB’S have been around since the late 1950s and still dominate the world market in sheer piece volume. Single-sided printed circuit boards are easily designed and quickly manufactured. They serve as the most cost effective platform in the industry.

How Are Single Sided PCBs Made?

One thin layer of thermally conductive but electrically insulating dielectric is laminated with copper. Soldermask is usually applied on top of the copper.

Benefits of Single Sided PCBs

Ideal for simple low-density designs

Lower cost, especially for high volume orders

Lower probability of manufacturing issues

Popular, common, and easily understood by most PCB manufacturers

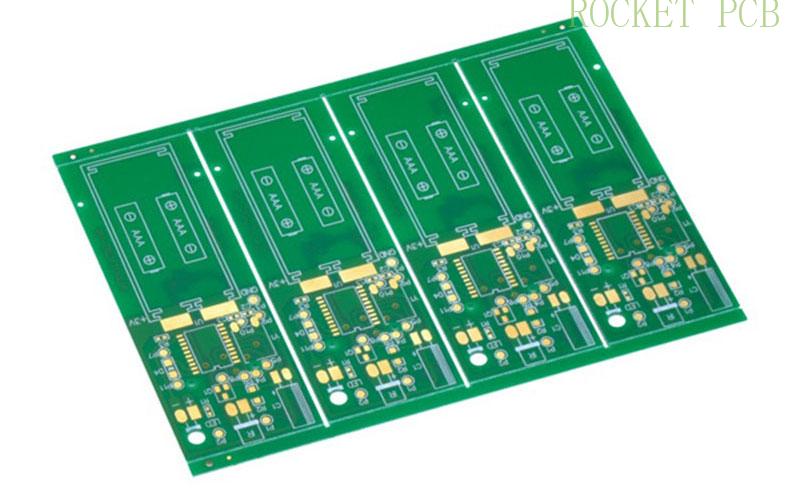

Rocket PCB produces prototype, midrange and high volume Single Sided circuit boards, with a copper thickness from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C. Single sided boards are available with surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Tin, and Gold plating along with both leaded or lead-free Hot Air Solder Level (HASL).

ALTHOUGH SINGLE SIDED PCBS ARE RELATIVELY SIMPLE, THEY CAN STILL BE USED IN VERY COMPLEX DEVICES:

Power supplies

Relays (automotive and industrial)

Timing circuits

Sensor products

LED lighting

Radio and stereo equipment

Packaging equipment

Surveillance

Calculators

Printers

Coffee makers

Vending machines

Solid state drives

Camera systems

At Rocket PCB,we've been using A-class FR4 materials, never scrimp, our technique is small profits but quick turnover, so within the premise of quality assurance, our PCB cost is extremely competitive.

Single sided pcb from Rocket is very common in both PCB production and PCB prototype circuits allowing a higher density between components and it makes the layering of tracks an easier process. Compared to the multilayer PCB, single sided pcb do not need laminating but need plating in order to realize the function of vias. If you are looking for custom pcb board, Rocket is capable and will give you full countenance in the format of one-stop PCB solution.