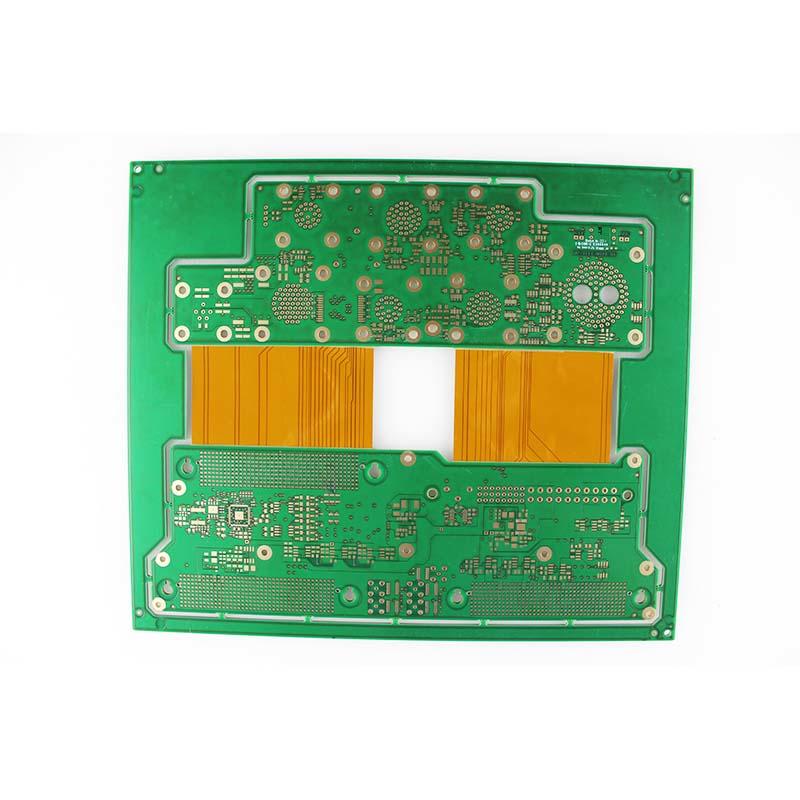

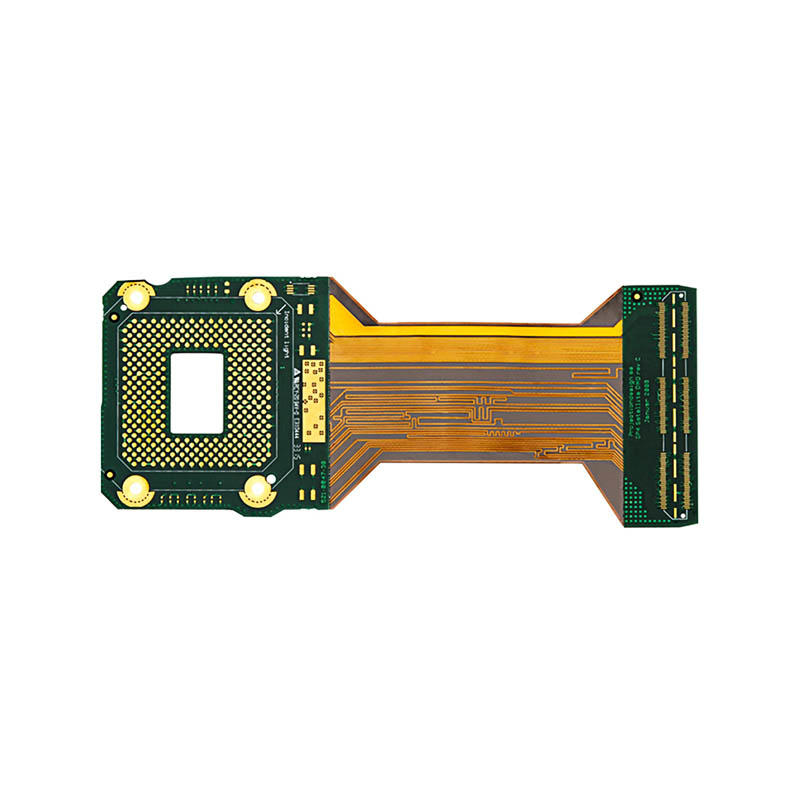

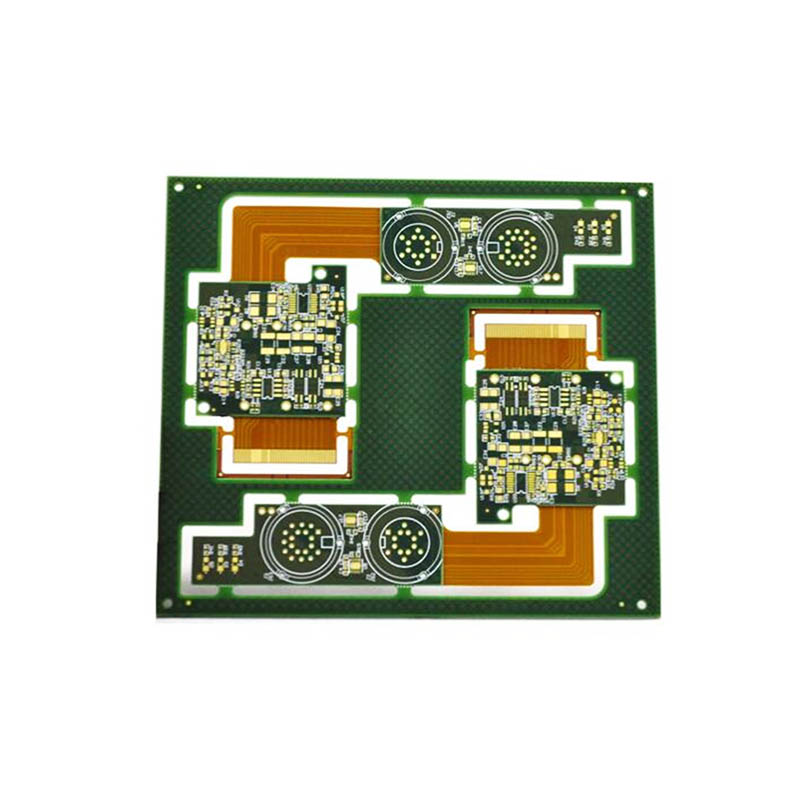

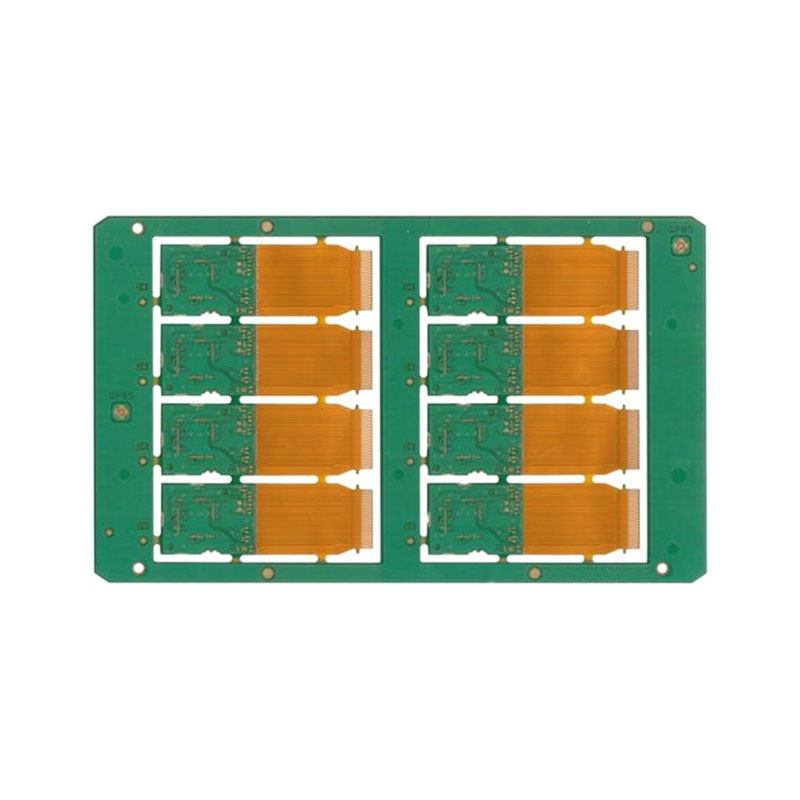

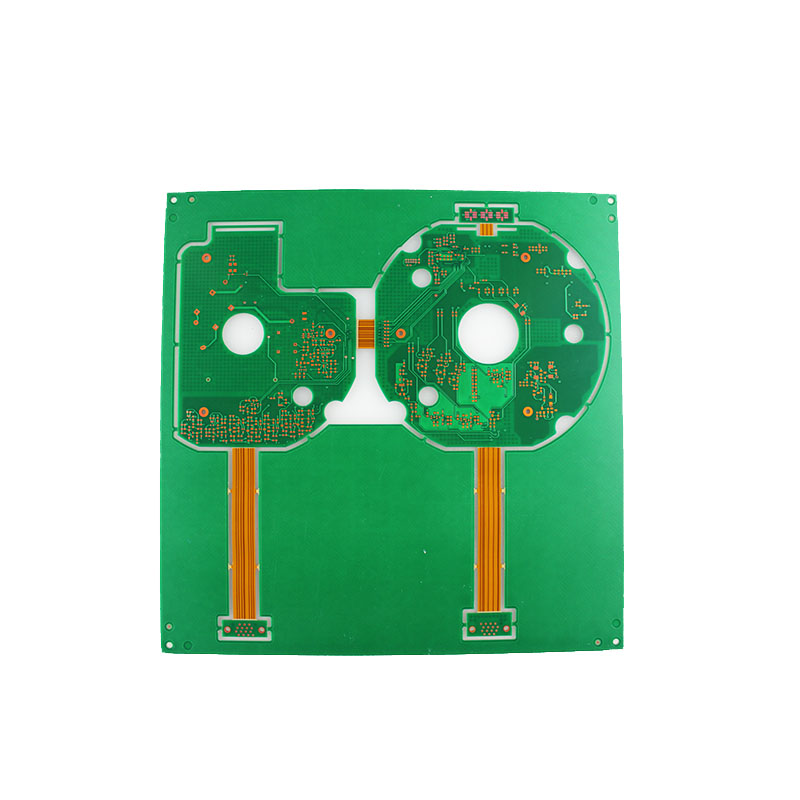

Rigid-flex board is a new type of printed circuit board with both durability of rigid PCB and adaptability of flexible PCB. In all types of PCB, rigid-flex board is the most resistant to harsh application environment, so it is favored by medical and military equipment manufacturers. Our country's enterprises are also gradually increasing the proportion of rigid-flex board in the total output.

Physical properties

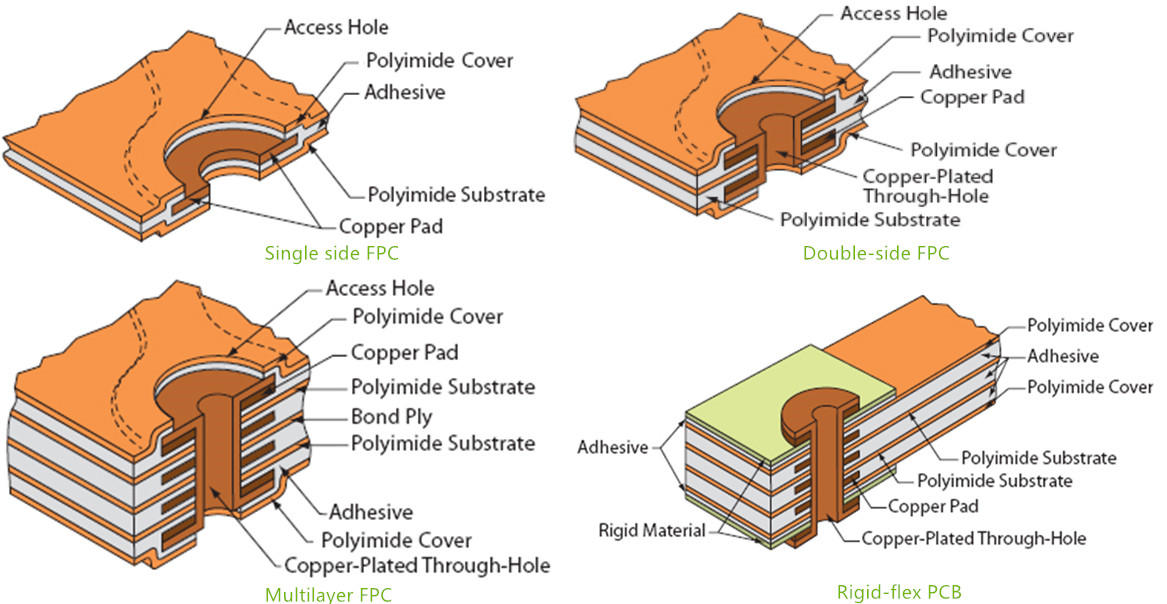

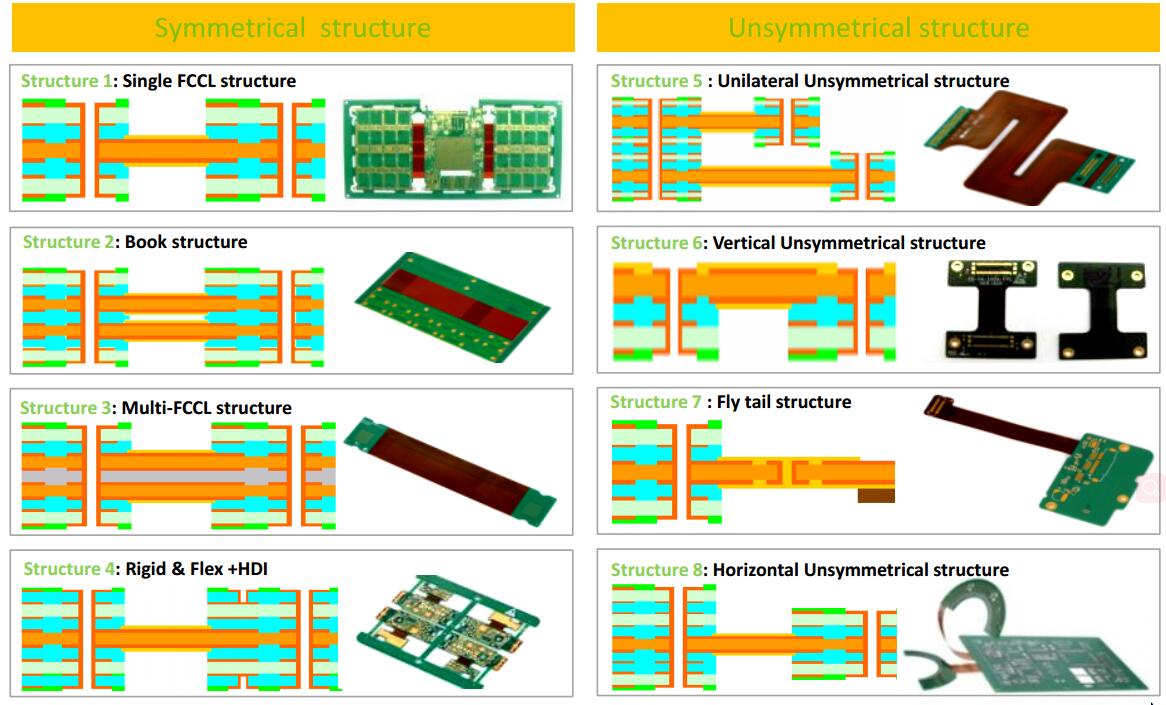

Rigid-flex PCB differs from rigid boards or flexible boards in material, equipment and process.

In terms of material, the material of rigid board is FR4 of PCB, and the material of flexible board is PI or PET. There are some problems between the two materials, such as joint, different shrinkage rate of hot pressing, etc. It is difficult for the stability of the product. Moreover, due to the characteristics of three-dimensional space configuration, besides the consideration of XY axis direction stress, Z axis direction stress bearing is also an important consideration. At present, material suppliers provide rigid-flex PCB manufacturers with improved materials suitable for rigid-flex board, such as epoxy or Resin, to meet the joint problem between PCB rigid board or flexible board.

In terms of equipment, due to the difference of material characteristics and product specifications, the equipment of lamination and copper plating parts must be modified. The applicability of equipment will affect the yield and stability of products. Therefore, the applicability of equipment should be considered before entering the production of rigid-flex PCB.

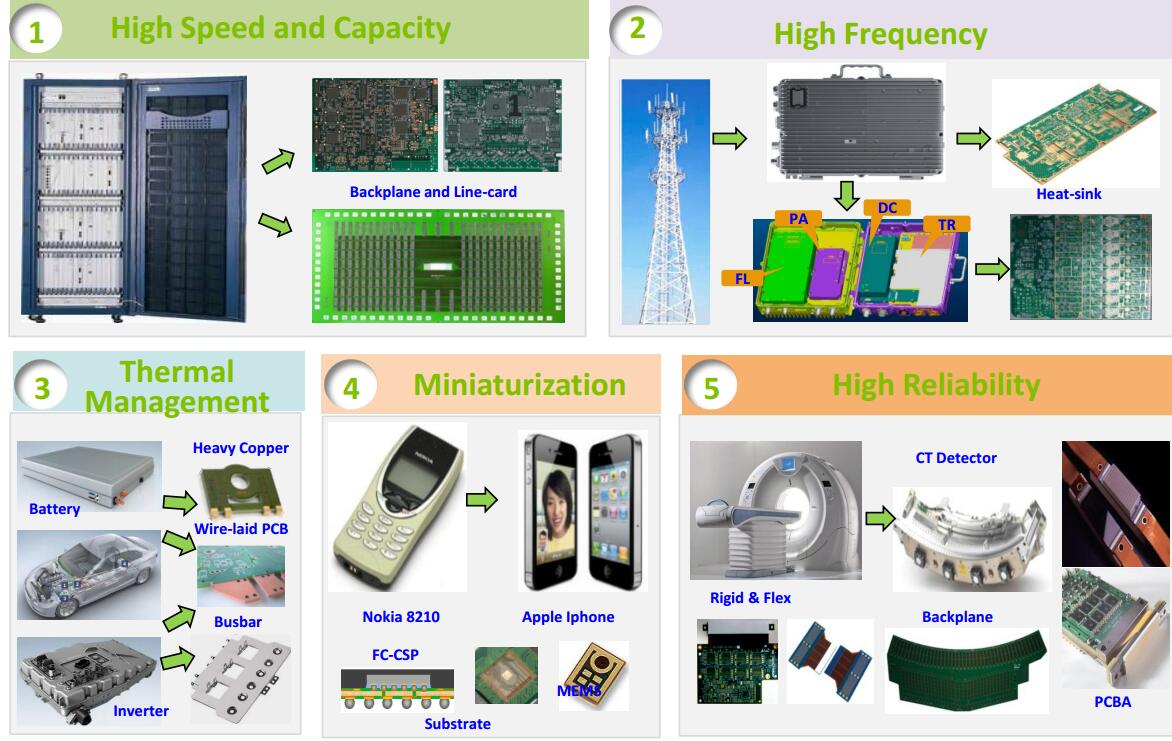

Comparing with general PCB, the advantages of rigid-flex PCB are as follows

Three‐dimensional assembly

Enables optimized packaging, can be bent or folded to fit into small device enclosures.

Increase system reliability

Improves reliability by eliminating separate boards, cables and connectors.

Reduce assembly error

Reduces the errors common in hand wired assemblies.

Reduce packaging complexity

Substantial weight & packaging size reduction is a benefit over wires an wire harnesses.

Better signal transfer

Minimal geometry changes to cause impedance discontinuities

Reduce assembly cost

Cost reduction in purchasing, logistics and assembling because of economisation of extra cables, connectors and soldering processes.

Rocket PCB is an innovative manufacturer focusing on electronic manufacturing. Rocket PCB is dedicated to spending 10 years of efforts advancing itself. We develop, produce and sell numerous successful high-quality products, including rigid, rigid-flex, HDI, any layer, Flex, large-size, embedded, RF, LED, backplane, metal substrate, ceramic substrate, IC structure, high-frequency, heavy copper. High quality and high reliability.

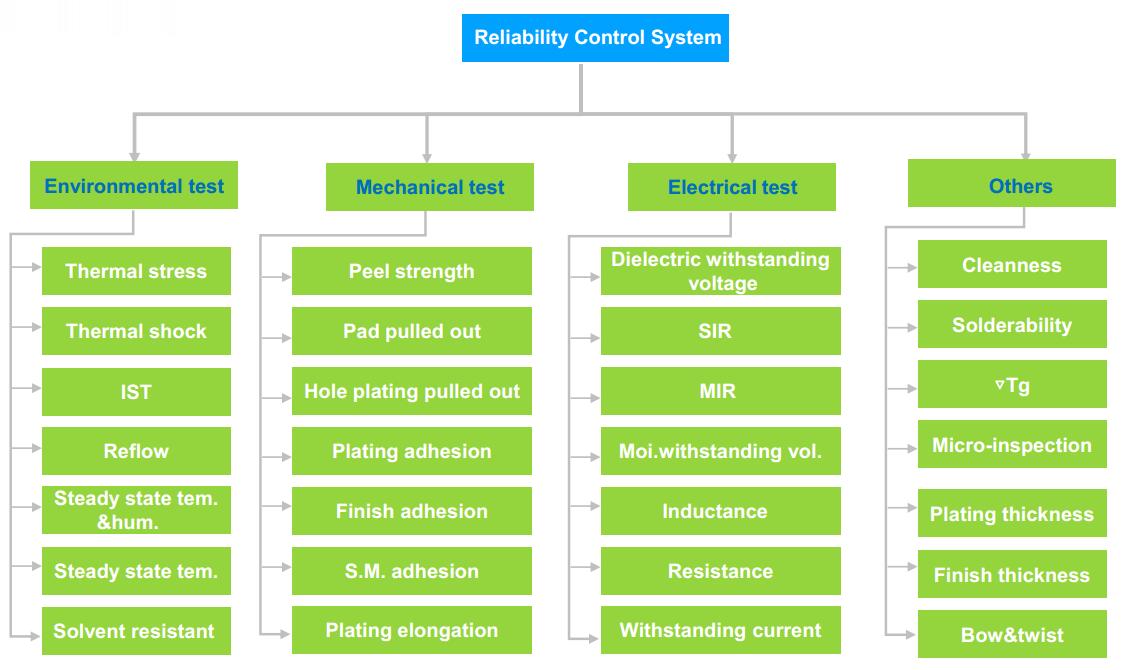

Quality management system is the brain center of quality control, strictly carry out quality inspection from incoming to outgoing and control every checkpoint is what we must fulfill every day. The supervision of rocket PCB has gone far beyond the normal level of the industry and national and international standards.

◪ 24

hour real-time technical support. Fast turn around with 24 hours and

fast quote in 2 hours for standard board.

◪ Effective and flexible PCB engineering solutions save your cost. We always focus on customer first when providing innovative solutions for manufacturing clients' products,we are more than pleased to help customers grow.

◪ Rapid suggestions on the layout, build-up, panels, impedance, material selection, design rules, manufacturability, costs of different solutions, use of micro vias, gold plating, special laminates, etc.

◪ Strong partnerships with different reputed A-class material suppliers such as Rogers, Arlon, Nelco and Taconic can realize a fast service to a wide range of high frequency PCB applications.

◪ Dozens of tests such as open/short circuit testing( ET test), AOI, X-ray, impedance testing, solderability testing, thermal shock testing, metallographic micro-slicing analysis, halogen-free testing, etc. 100% OQC inspection.

◪ Complete services like free Design Rule Check (DRC), free DFM, traceable manufacturing to complete after-sales service, on time delivery 99%.

◪ We will keep secret for customer sale area, design ideas, drawing and all other private information.

◪ Flexible payment terms. Samples for 100%TT, mass production payment: 50% advance payment 50% balance should be paid off before loading or accept monthly statement based on the order volumes.

Copyright © 2026 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink