gm\'s road map to automated plants a proliferation of smart machines, unable to speak a common lingo, has been blocking the way to computerized factories. so general motors, leading a buyers\' uprising, has imposed a new standard that lets all the equipme

by:Rocket PCB

2019-09-19

(

Fortune magazine)

-Complex new technologies can be daunting, especially when they break out in a variety of incompatible manufacturing and designs.

Customers rarely step in to impose orders, prefer to wait until the manufacturer does so collectively, or more often, wait until the successful product line of the competitor sets the standard for everyone. Yet in a full-

The scale of customer resistance, big companies have taken action to force compatibility on the whole of the electronic brain, robots and machine tools that make up the future factory.

GM, with its huge purchasing power, led the uprising, which helped it.

By the end of 1970, GM\'s manufacturing executives saw a surge in computer systems and \"smart\" production machines, each of which could only communicate with a limited number of other devices, resulting in a piecemeal automation. -

Babel of Electronic Languages--

On the floor of the factory

This hinders the realization of \"computer-

Integrated manufacturing in which each part of the production process is connected together by a central nervous system.

In hope

Because the benefit of this system is unprecedented coordination of the entire plant: excessive production or defects of any part or sub-assembly can be detected immediately, and the machine can be switched in a few minutes, produce different products.

As GM and its ally\'s factories have used standardized new communication systems on a limited scale, including Deere, Boeing, and Eastman KodakKnown as MAP --

Protocol for manufacturing automation-

The network connects machines with multiple languages, allowing them to talk in Esperanto.

In early November, MAP will be unveiled at the Autofact auto-manufacturing exhibition in the Cobo Hall in Detroit.

To demonstrate the flexibility of computer manufacturing, television will be broadcast to Europe via satellite, unlike

Computer machines and robots from various manufacturers will assemble colorful versions of plastic toys.

To select the color, visitors simply stand up and press a button.

It\'s not easy to go there.

GM initially encountered resistance from big companies such as digital devices and Hewlett-Packard in terms of factory computerisation.

Packard has a stake in proprietary networks that will provide customers with limited products, mainly their own.

These companies have reason to worry about a network that can accommodate any competitor\'s products.

But now, with enthusiasm for a system that promises to benefit all by expanding its overall business, the old parochialism has been swallowed up.

Alan Selli, general manager of Hewlett, said: \"American companies and European companies lag behind the map

The network department of Packard

Although Japanese companies started late, they started to cause a stir.

Fanuc, GM\'s partner in the robotics enterprise GMF, announced that it will use MAP at its own factory and will make the equipment it sells compatible with the new network.

Recently, delegates from 200 Japanese companies attended GM\'s briefing on the map.

It is widely believed that this will speed up the day of the push --

Where The Button Factory is used.

The authority on this issue is Dennis E.

Wisnosky, group vice president of industrial systems at GCA.

A manufacturer of automation equipment that produces semiconductor chips.

Smart Sky said: \"The map will bring about the realization of real computers --

Integrated manufacturing may be five to ten years earlier than the original situation.

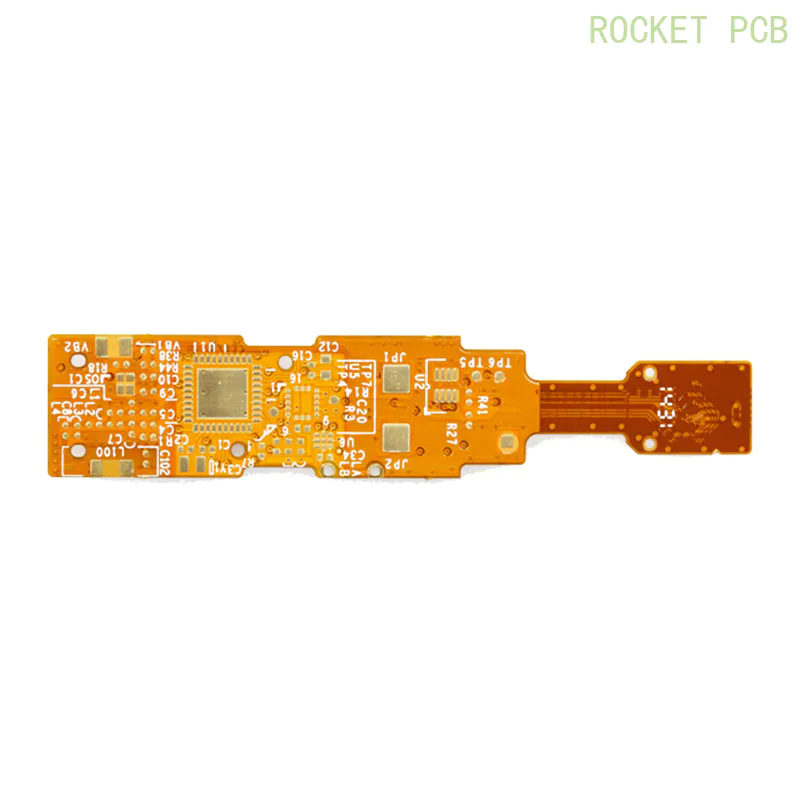

Essentially, MAP is a highly complex version of the LAN that connects office and factory electronics.

But most local area networks, such as Decnet or Allen for digital devices-

Bradley\'s data highway is proprietary.

They only connect a limited range of devices without a lot of customization--

Mainly do Lan

MAP has no patents and can be copied for free by all, it connects almost any equipment needed for the automation plant, including imported machines now and in the future.

In the physical appearance, MAP replaces an isolated wiring that is usually just as pleasant and ugly with a multi-channel coaxial cable

Inches in diameter, can be buried in the ceiling or on the floor.

Similar to cable TV that offers TV programs to homes, it can transmit impressive ten megabits of data per second-

It is equivalent to 1,250 typing pages.

This is enough for the cable to perform additional duties such as carrying the sound and turning off-

Communication of circuit TV and operation of factory safety system. Hewlett-

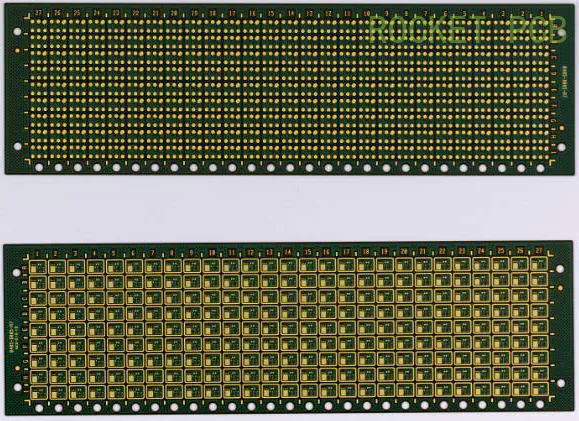

Packard puts the map into two factories in Roseville, California that produce printed circuit boards and will use it to send training movie highlights to workers\' benches.

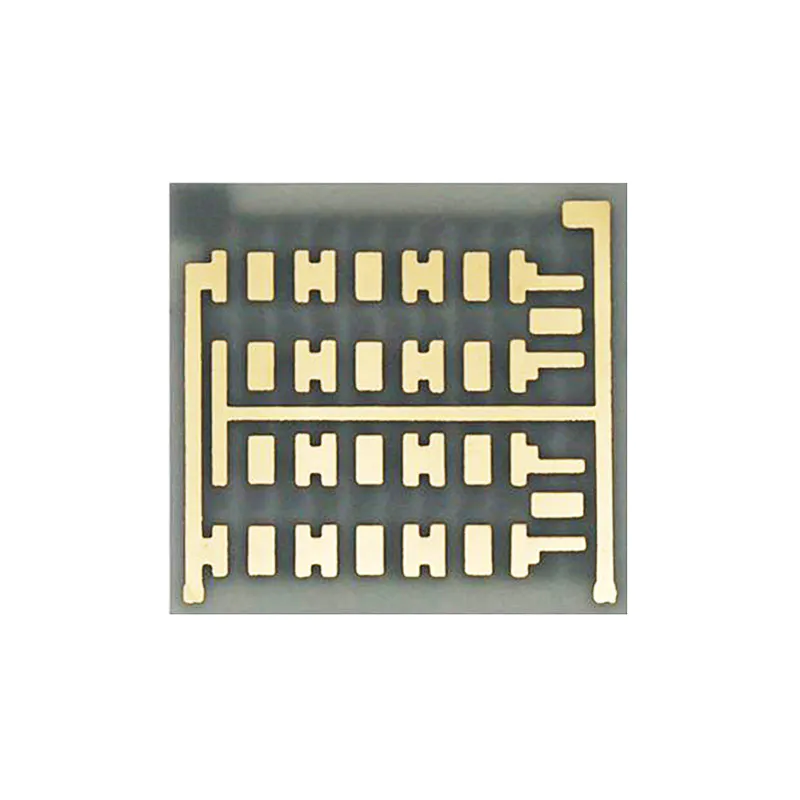

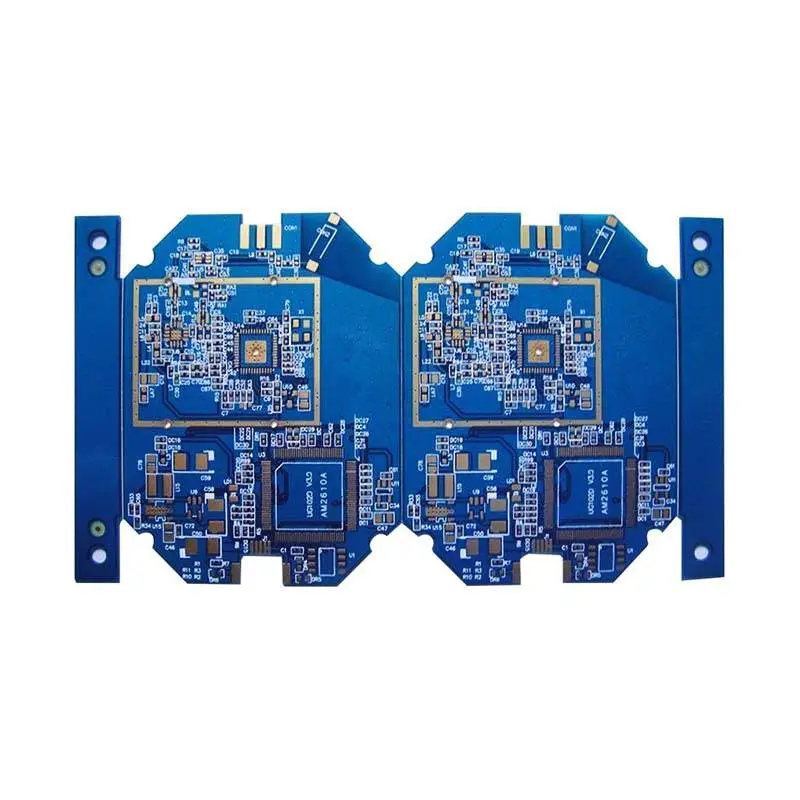

Computers, robots and machine tools mechanically plug cables through electronic black boxes and printed circuit board arrays.

The software combines complex software as an \"interface\" to convert the signals of each machine into a common language \".

While proprietary networks may be replaced by maps, they can also be equipped with translation equipment and connected to the system.

One of the greatest advantages of the map is the eyes of the engineers.

In most local area networks, information between individual electronic devices must compete in order to use a central channel.

When two or more machines try to \"shout down\" the internet, this can cause delay and loss of data transmission.

Maps will usher in the first widespread use of \"tokens\" or baton

Through the system that ensures that each machine quickly rotates into the production line.

Shouting no data disappear in the game-

In computer chemical plants, speed can prevent production fluctuations, which is very important. -

The message passed quickly.

The map saves time and money by simply connecting all the machines in the factory together.

Spread in Deere, 96-

Acre combine harvester and Harvester factory in East Morin, Illinois, individual program for CNC machine tools, punching holes on tape in central computer room, must be handmade

Carried to the floor of the factory.

If an error is found in the program, it must be re-punched, a process that can leave the machine idle for half a day or more.

Now, the instructions go from so-through a network compatible with MAP-

In the computer room is called distributed numerical control system.

If there is an error due to any other reason or the program of the machine needs to be changed, the new instructions can be sent in a few minutes and production can be restored quickly.

MAP\'s most influential champion was GM Chairman Roger Smith, who said, \"Without it, the factory of the future will never be a reality.

The concept actually penetrated into the top level from manufacturing executives and engineers who saw half of it

More than a decade ago, GM built a \"communication monster\" in its factory \".

The company is building automated silos controlled by up to a dozen independent networks rather than unified production systems.

Each group of computers-

For example, stamping machines with robots and inspection devices--

Operate on your own.

Later, a study by Eastman Kodak showed that compatibility was a heavy price.

Many independent networks need to be customized

The software written, written only these software consumes the third part of the installation time.

Install and connect computer clusters--

Specially customized cabling and software and training--

Half their cost.

Once heterogeneous systems are in operation, it takes a lot of power to maintain them.

Even so, not all machines of the same manufacturer can communicate with each other.

Most of the time, a team called \"sports shoe network --

Humans with feet must bridge this gap.

Like Deere\'s peers, they transfer data from one machine to another.

In 1980, the GM set up a task force of delegates from seven divisions to develop maps.

Two years later, the company\'s top management persuaded the MAP to become a highway to tomorrow\'s factory, and GM announced that it would use the network in all factories and asked equipment manufacturers to follow MAP\'s interconnected standards.

In a world where standards are usually determined by leading suppliers such as IBM or AT&T, it is a considerable shift for leading customers to make rules.

Some suppliers are angry.

What was initially strongly resisted was the digital device, whose widely used Decnet system has been in development for 15 years and has stimulated the company\'s sales of computers used in factories.

In an effort to make these boycotts a reality, GM has tricked and tricked other online suppliers.

Michael A is an important persuasion.

Carminsky, 52, is the company\'s map project manager, and his bulldog\'s tenacity makes up for his lack of shape.

He\'s only five years old.

Four people said, \"my fist is very big.

Carminsky sometimes tells lies of kindness.

He recalled that in Alan Brad, the leader close to the field of factory automation, \"I would say, \'We got Gould, \'and then Alan --

Bradley will say, well, we will attend if you have Gould.

Then I will go back to Gould and say, we have Alan.

Bradley, it\'s best to join you.

I\'m not saying we\'re not fair or we\'re playing dirty pool games.

We can see that the map is in the right direction and we just point out to the supplier the opportunity they can\'t see.

When the conversation failed, carminsky exercised the muscles of GM.

He suggested to the company that if their devices are not compatible with the map network, it may be difficult to sell to GM in the future.

Since then, in fact, compatibility with MAP has become part of the car manufacturer\'s purchase policy.

When carminsky discovered that some network suppliers responded in a half-hearted way ---

Plans to accommodate GM but continue selling their proprietary systems elsewhere ---

He decided that suppliers could only get on track if concerted action was taken between customers.

So with the help of some of McDonald Douglas\'s federations, GM organized a map user organization.

To make the map attractive, carminsky recruited not only Ford and Chrysler, but also a large number of companies outside the automotive industry.

The membership of the organization increased rapidly.

About 60 participants representing 45 companies attended the group in St. Louis in 1984.

The recent secret conference in Anaheim, California, attracted more than 500 people from 240 companies.

The GM technology center conference held in Warren, Michigan in 1984 was an important turning point.

Prior to this, despite the great influence of GM, the supplier made users a little scared and the atmosphere was cold.

Recalling an AT&T engineer who acted as a user on behalf of his company: \"I found Hewlett --

My side is Packard and IBM on the other side, behind me is a digital device.

You hardly dare to say it at first.

But a strange thing happened 15 to 20 minutes later. -

The whole room was open.

It\'s like people throw away their company name tags.

In a changing atmosphere, once reluctant equipment manufacturers were quickly pressured by their peers.

When a speaker from digital devices went up to extoll Decnet after everyone else had a good review of the map, he was booed.

The numbers defend its long feet. Drag on map

Kevin O\'Neill, who is in charge of the company\'s manufacturing network marketing, said the company is concerned about the high cost of introducing a new system.

He said his company also pulled out of MAP because it didn\'t like the way GM didn\'t keep changing specs until last year.

Now Digital is a supporter of the map.

At a recent user conference, Gould announced that he would abandon his proprietary network, Modway, and instead support maps.

There are about 100 suppliers of equipment and components, starting in small Silicon Valley-

The map has been signed. There is IBM.

Compared with some competitors, Dalan has a relatively small stake in factory automation, no proprietary network, and never shows too much resistance.

Motorola estimates that the supply of cables, mechanical connectors, circuit boards and black boxes will grow to $1 billion a year by 1988.

Cable suppliers include Belden and time fiber communications from Cooper Industries.

Due to the complexity of the map, it is more expensive than a proprietary network.

However, the increase in compatibility exceeds the increased cost, and as semiconductor manufacturers enter the game, the cost will inevitably drop, reducing the cost of components by executing components on dedicated silicon chips.

Leading this electronic contraction is industrial network companies. (INI)

The only company in Santa Clara, California, does nothing but map network components.

Founded by Ungermann last year

Bass that provides chips and other components for Xerox\'s Ethernet LAN, and INI also gets $6

GE owns a 40% stake.

INI beat larger rivals with the first complete set of map products, including chips for two shunt signals as well as software and printed circuit boards. Joseph P.

Schoendorf, president of INI, believes sales will reach $100 million in five years.

When the big semiconductor companies start to spit out the map chips, there will be a lot of companies in INI.

Motorola and Intel have already offered several products, and more will be launched soon.

Nevertheless, the MAP is still in the stage of development and stability.

Different engineers have slightly different explanations for detailed standards and specifications.

In a small bump on the map, it was recently discovered that the modems of three different companies could not talk to each other.

As a temporary solution, Alan and other suppliers

To ensure compatibility, Bradley had to equip their process controllers with three printed circuit boards instead of one.

However, these problems seem to be overcome.

To ensure that \"smart\" machines speak map languages, the Institute of Industrial Technology in Ann Arbor, Michigan, an independent research organization, has begun testing them.

Its imprimatur will be somewhat similar to the underwriter lab label on electrical equipment.

While GM is more committed to maps than any other company, it is still careful to install the network.

The Electronic Data Systems subsidiary of the automaker acquired in 1984 will purchase all equipment and oversee the installation.

In some genetically modified plants, due to the aversion of many plant managers to change, MAP received a cold reception and even encountered some resistance.

So there is a lot of education and training to be done in the future.

GM has already launched pilot projects in several factories, including limited map networks.

The wider network will be operational next year, including a network of a factory in Saginaw, Michigan that will make axles for forward carswheel drive.

There will be 50 \"cells\" or computer clusters in the factory

Running the machine, each machine contains equipment such as robots and CNC machine tools.

With MAP, the manager of the factory will be able to order the switch to produce different types of axles ---

All tool changes--

Just press the button.

It will take three days to convert now;

The map will be shortened to ten minutes.

Elsewhere in Saginaw and GM, machines that automatically check if the newly manufactured parts are defective will be able to issue a timely warning to the machines that make them through maps.

This will avoid the accumulation of defective parts, which is a common headache problem in automation factories.

GM plans to make Maps popular at the factory by 1990.

Through early embrace maps, GM and other US companiesS.

So far, manufacturers want to surpass Japan as a pacesetter for factory automation.

The wisdom sky of GCA

Think there are three American companies. to five-

Map of Japan begins a year.

He allowed Japan and other countries to try to catch up.

\"If our machine controllers and robots are the first to be compatible with maps, then the rest of the world will have to follow us,\" said Smart sky . \".

\"If maps become common, the work of computer chemical plants can be effectively distributed among countries as never before.

Map network can be extended beyond a single factory for a long time

Telephone lines and communication satellites.

Assuming Italians are considered the best person to design a new car, the Japanese seem to be the best person to produce a power train, as well as factories close to major U. S. cities, Wisnosky saidS.

As a meeting point, the market is the most meaningful.

Design and tools can be choreographed across borders-

Instant communication--through MAP.

This will not only allow new cars to enter the exhibition hall faster, but also bring a new dimension to the global division of labor.

Box: General Motors sales of investors snapshot (

Last four quarters$88.

Net profit of $6 billion increased by 7% year on year.

5 billion return on equity of common shareholders decreased by 33% 5-8%

Average annual 14% recent stock price $67 P/E 6 total return to investors (

12 months to 9/30)-

Fortune magazine)

-Complex new technologies can be daunting, especially when they break out in a variety of incompatible manufacturing and designs.

Customers rarely step in to impose orders, prefer to wait until the manufacturer does so collectively, or more often, wait until the successful product line of the competitor sets the standard for everyone. Yet in a full-

The scale of customer resistance, big companies have taken action to force compatibility on the whole of the electronic brain, robots and machine tools that make up the future factory.

GM, with its huge purchasing power, led the uprising, which helped it.

By the end of 1970, GM\'s manufacturing executives saw a surge in computer systems and \"smart\" production machines, each of which could only communicate with a limited number of other devices, resulting in a piecemeal automation. -

Babel of Electronic Languages--

On the floor of the factory

This hinders the realization of \"computer-

Integrated manufacturing in which each part of the production process is connected together by a central nervous system.

In hope

Because the benefit of this system is unprecedented coordination of the entire plant: excessive production or defects of any part or sub-assembly can be detected immediately, and the machine can be switched in a few minutes, produce different products.

As GM and its ally\'s factories have used standardized new communication systems on a limited scale, including Deere, Boeing, and Eastman KodakKnown as MAP --

Protocol for manufacturing automation-

The network connects machines with multiple languages, allowing them to talk in Esperanto.

In early November, MAP will be unveiled at the Autofact auto-manufacturing exhibition in the Cobo Hall in Detroit.

To demonstrate the flexibility of computer manufacturing, television will be broadcast to Europe via satellite, unlike

Computer machines and robots from various manufacturers will assemble colorful versions of plastic toys.

To select the color, visitors simply stand up and press a button.

It\'s not easy to go there.

GM initially encountered resistance from big companies such as digital devices and Hewlett-Packard in terms of factory computerisation.

Packard has a stake in proprietary networks that will provide customers with limited products, mainly their own.

These companies have reason to worry about a network that can accommodate any competitor\'s products.

But now, with enthusiasm for a system that promises to benefit all by expanding its overall business, the old parochialism has been swallowed up.

Alan Selli, general manager of Hewlett, said: \"American companies and European companies lag behind the map

The network department of Packard

Although Japanese companies started late, they started to cause a stir.

Fanuc, GM\'s partner in the robotics enterprise GMF, announced that it will use MAP at its own factory and will make the equipment it sells compatible with the new network.

Recently, delegates from 200 Japanese companies attended GM\'s briefing on the map.

It is widely believed that this will speed up the day of the push --

Where The Button Factory is used.

The authority on this issue is Dennis E.

Wisnosky, group vice president of industrial systems at GCA.

A manufacturer of automation equipment that produces semiconductor chips.

Smart Sky said: \"The map will bring about the realization of real computers --

Integrated manufacturing may be five to ten years earlier than the original situation.

Essentially, MAP is a highly complex version of the LAN that connects office and factory electronics.

But most local area networks, such as Decnet or Allen for digital devices-

Bradley\'s data highway is proprietary.

They only connect a limited range of devices without a lot of customization--

Mainly do Lan

MAP has no patents and can be copied for free by all, it connects almost any equipment needed for the automation plant, including imported machines now and in the future.

In the physical appearance, MAP replaces an isolated wiring that is usually just as pleasant and ugly with a multi-channel coaxial cable

Inches in diameter, can be buried in the ceiling or on the floor.

Similar to cable TV that offers TV programs to homes, it can transmit impressive ten megabits of data per second-

It is equivalent to 1,250 typing pages.

This is enough for the cable to perform additional duties such as carrying the sound and turning off-

Communication of circuit TV and operation of factory safety system. Hewlett-

Packard puts the map into two factories in Roseville, California that produce printed circuit boards and will use it to send training movie highlights to workers\' benches.

Computers, robots and machine tools mechanically plug cables through electronic black boxes and printed circuit board arrays.

The software combines complex software as an \"interface\" to convert the signals of each machine into a common language \".

While proprietary networks may be replaced by maps, they can also be equipped with translation equipment and connected to the system.

One of the greatest advantages of the map is the eyes of the engineers.

In most local area networks, information between individual electronic devices must compete in order to use a central channel.

When two or more machines try to \"shout down\" the internet, this can cause delay and loss of data transmission.

Maps will usher in the first widespread use of \"tokens\" or baton

Through the system that ensures that each machine quickly rotates into the production line.

Shouting no data disappear in the game-

In computer chemical plants, speed can prevent production fluctuations, which is very important. -

The message passed quickly.

The map saves time and money by simply connecting all the machines in the factory together.

Spread in Deere, 96-

Acre combine harvester and Harvester factory in East Morin, Illinois, individual program for CNC machine tools, punching holes on tape in central computer room, must be handmade

Carried to the floor of the factory.

If an error is found in the program, it must be re-punched, a process that can leave the machine idle for half a day or more.

Now, the instructions go from so-through a network compatible with MAP-

In the computer room is called distributed numerical control system.

If there is an error due to any other reason or the program of the machine needs to be changed, the new instructions can be sent in a few minutes and production can be restored quickly.

MAP\'s most influential champion was GM Chairman Roger Smith, who said, \"Without it, the factory of the future will never be a reality.

The concept actually penetrated into the top level from manufacturing executives and engineers who saw half of it

More than a decade ago, GM built a \"communication monster\" in its factory \".

The company is building automated silos controlled by up to a dozen independent networks rather than unified production systems.

Each group of computers-

For example, stamping machines with robots and inspection devices--

Operate on your own.

Later, a study by Eastman Kodak showed that compatibility was a heavy price.

Many independent networks need to be customized

The software written, written only these software consumes the third part of the installation time.

Install and connect computer clusters--

Specially customized cabling and software and training--

Half their cost.

Once heterogeneous systems are in operation, it takes a lot of power to maintain them.

Even so, not all machines of the same manufacturer can communicate with each other.

Most of the time, a team called \"sports shoe network --

Humans with feet must bridge this gap.

Like Deere\'s peers, they transfer data from one machine to another.

In 1980, the GM set up a task force of delegates from seven divisions to develop maps.

Two years later, the company\'s top management persuaded the MAP to become a highway to tomorrow\'s factory, and GM announced that it would use the network in all factories and asked equipment manufacturers to follow MAP\'s interconnected standards.

In a world where standards are usually determined by leading suppliers such as IBM or AT&T, it is a considerable shift for leading customers to make rules.

Some suppliers are angry.

What was initially strongly resisted was the digital device, whose widely used Decnet system has been in development for 15 years and has stimulated the company\'s sales of computers used in factories.

In an effort to make these boycotts a reality, GM has tricked and tricked other online suppliers.

Michael A is an important persuasion.

Carminsky, 52, is the company\'s map project manager, and his bulldog\'s tenacity makes up for his lack of shape.

He\'s only five years old.

Four people said, \"my fist is very big.

Carminsky sometimes tells lies of kindness.

He recalled that in Alan Brad, the leader close to the field of factory automation, \"I would say, \'We got Gould, \'and then Alan --

Bradley will say, well, we will attend if you have Gould.

Then I will go back to Gould and say, we have Alan.

Bradley, it\'s best to join you.

I\'m not saying we\'re not fair or we\'re playing dirty pool games.

We can see that the map is in the right direction and we just point out to the supplier the opportunity they can\'t see.

When the conversation failed, carminsky exercised the muscles of GM.

He suggested to the company that if their devices are not compatible with the map network, it may be difficult to sell to GM in the future.

Since then, in fact, compatibility with MAP has become part of the car manufacturer\'s purchase policy.

When carminsky discovered that some network suppliers responded in a half-hearted way ---

Plans to accommodate GM but continue selling their proprietary systems elsewhere ---

He decided that suppliers could only get on track if concerted action was taken between customers.

So with the help of some of McDonald Douglas\'s federations, GM organized a map user organization.

To make the map attractive, carminsky recruited not only Ford and Chrysler, but also a large number of companies outside the automotive industry.

The membership of the organization increased rapidly.

About 60 participants representing 45 companies attended the group in St. Louis in 1984.

The recent secret conference in Anaheim, California, attracted more than 500 people from 240 companies.

The GM technology center conference held in Warren, Michigan in 1984 was an important turning point.

Prior to this, despite the great influence of GM, the supplier made users a little scared and the atmosphere was cold.

Recalling an AT&T engineer who acted as a user on behalf of his company: \"I found Hewlett --

My side is Packard and IBM on the other side, behind me is a digital device.

You hardly dare to say it at first.

But a strange thing happened 15 to 20 minutes later. -

The whole room was open.

It\'s like people throw away their company name tags.

In a changing atmosphere, once reluctant equipment manufacturers were quickly pressured by their peers.

When a speaker from digital devices went up to extoll Decnet after everyone else had a good review of the map, he was booed.

The numbers defend its long feet. Drag on map

Kevin O\'Neill, who is in charge of the company\'s manufacturing network marketing, said the company is concerned about the high cost of introducing a new system.

He said his company also pulled out of MAP because it didn\'t like the way GM didn\'t keep changing specs until last year.

Now Digital is a supporter of the map.

At a recent user conference, Gould announced that he would abandon his proprietary network, Modway, and instead support maps.

There are about 100 suppliers of equipment and components, starting in small Silicon Valley-

The map has been signed. There is IBM.

Compared with some competitors, Dalan has a relatively small stake in factory automation, no proprietary network, and never shows too much resistance.

Motorola estimates that the supply of cables, mechanical connectors, circuit boards and black boxes will grow to $1 billion a year by 1988.

Cable suppliers include Belden and time fiber communications from Cooper Industries.

Due to the complexity of the map, it is more expensive than a proprietary network.

However, the increase in compatibility exceeds the increased cost, and as semiconductor manufacturers enter the game, the cost will inevitably drop, reducing the cost of components by executing components on dedicated silicon chips.

Leading this electronic contraction is industrial network companies. (INI)

The only company in Santa Clara, California, does nothing but map network components.

Founded by Ungermann last year

Bass that provides chips and other components for Xerox\'s Ethernet LAN, and INI also gets $6

GE owns a 40% stake.

INI beat larger rivals with the first complete set of map products, including chips for two shunt signals as well as software and printed circuit boards. Joseph P.

Schoendorf, president of INI, believes sales will reach $100 million in five years.

When the big semiconductor companies start to spit out the map chips, there will be a lot of companies in INI.

Motorola and Intel have already offered several products, and more will be launched soon.

Nevertheless, the MAP is still in the stage of development and stability.

Different engineers have slightly different explanations for detailed standards and specifications.

In a small bump on the map, it was recently discovered that the modems of three different companies could not talk to each other.

As a temporary solution, Alan and other suppliers

To ensure compatibility, Bradley had to equip their process controllers with three printed circuit boards instead of one.

However, these problems seem to be overcome.

To ensure that \"smart\" machines speak map languages, the Institute of Industrial Technology in Ann Arbor, Michigan, an independent research organization, has begun testing them.

Its imprimatur will be somewhat similar to the underwriter lab label on electrical equipment.

While GM is more committed to maps than any other company, it is still careful to install the network.

The Electronic Data Systems subsidiary of the automaker acquired in 1984 will purchase all equipment and oversee the installation.

In some genetically modified plants, due to the aversion of many plant managers to change, MAP received a cold reception and even encountered some resistance.

So there is a lot of education and training to be done in the future.

GM has already launched pilot projects in several factories, including limited map networks.

The wider network will be operational next year, including a network of a factory in Saginaw, Michigan that will make axles for forward carswheel drive.

There will be 50 \"cells\" or computer clusters in the factory

Running the machine, each machine contains equipment such as robots and CNC machine tools.

With MAP, the manager of the factory will be able to order the switch to produce different types of axles ---

All tool changes--

Just press the button.

It will take three days to convert now;

The map will be shortened to ten minutes.

Elsewhere in Saginaw and GM, machines that automatically check if the newly manufactured parts are defective will be able to issue a timely warning to the machines that make them through maps.

This will avoid the accumulation of defective parts, which is a common headache problem in automation factories.

GM plans to make Maps popular at the factory by 1990.

Through early embrace maps, GM and other US companiesS.

So far, manufacturers want to surpass Japan as a pacesetter for factory automation.

The wisdom sky of GCA

Think there are three American companies. to five-

Map of Japan begins a year.

He allowed Japan and other countries to try to catch up.

\"If our machine controllers and robots are the first to be compatible with maps, then the rest of the world will have to follow us,\" said Smart sky . \".

\"If maps become common, the work of computer chemical plants can be effectively distributed among countries as never before.

Map network can be extended beyond a single factory for a long time

Telephone lines and communication satellites.

Assuming Italians are considered the best person to design a new car, the Japanese seem to be the best person to produce a power train, as well as factories close to major U. S. cities, Wisnosky saidS.

As a meeting point, the market is the most meaningful.

Design and tools can be choreographed across borders-

Instant communication--through MAP.

This will not only allow new cars to enter the exhibition hall faster, but also bring a new dimension to the global division of labor.

Box: General Motors sales of investors snapshot (

Last four quarters$88.

Net profit of $6 billion increased by 7% year on year.

5 billion return on equity of common shareholders decreased by 33% 5-8%

Average annual 14% recent stock price $67 P/E 6 total return to investors (

12 months to 9/30)-

Custom message