Getting a Prototype Printed Circuit Board (PCB):

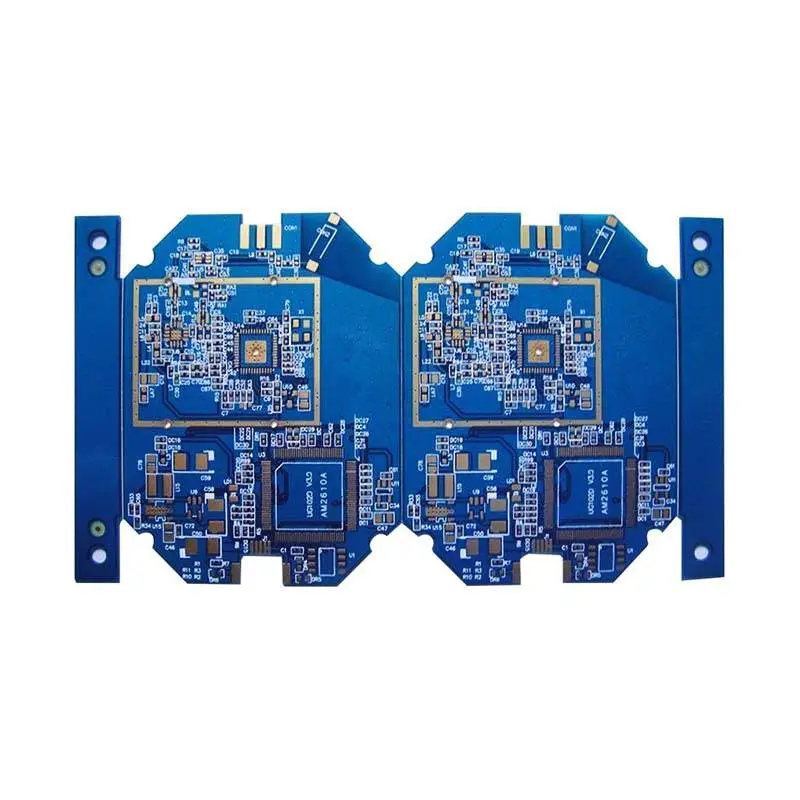

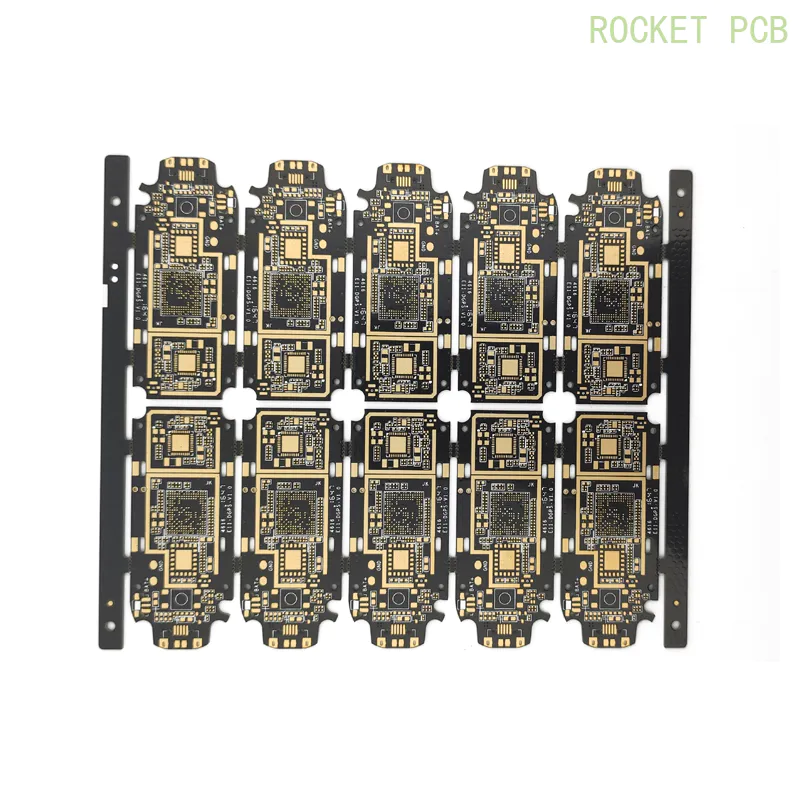

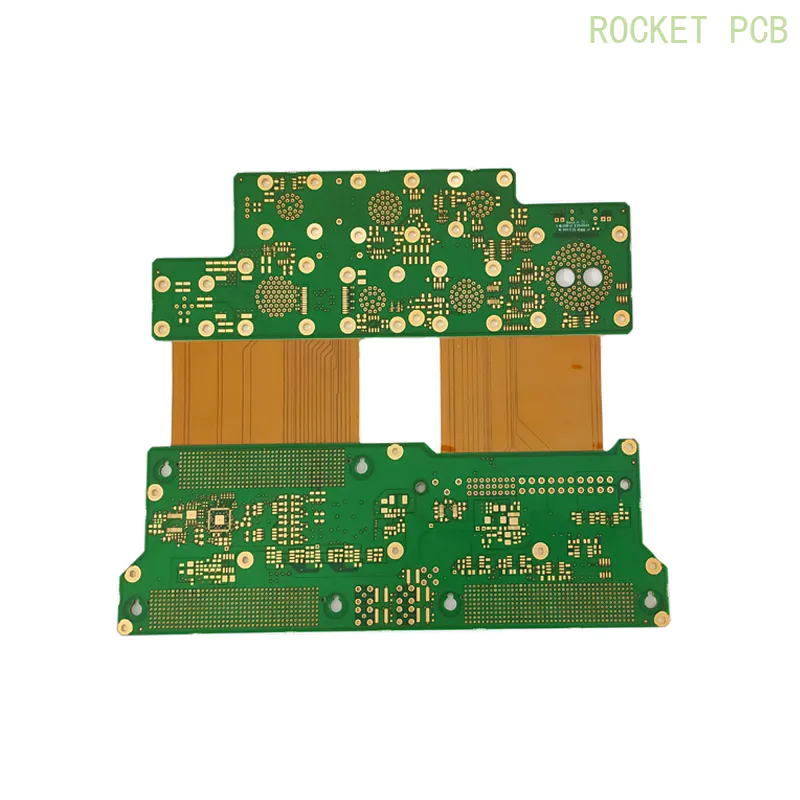

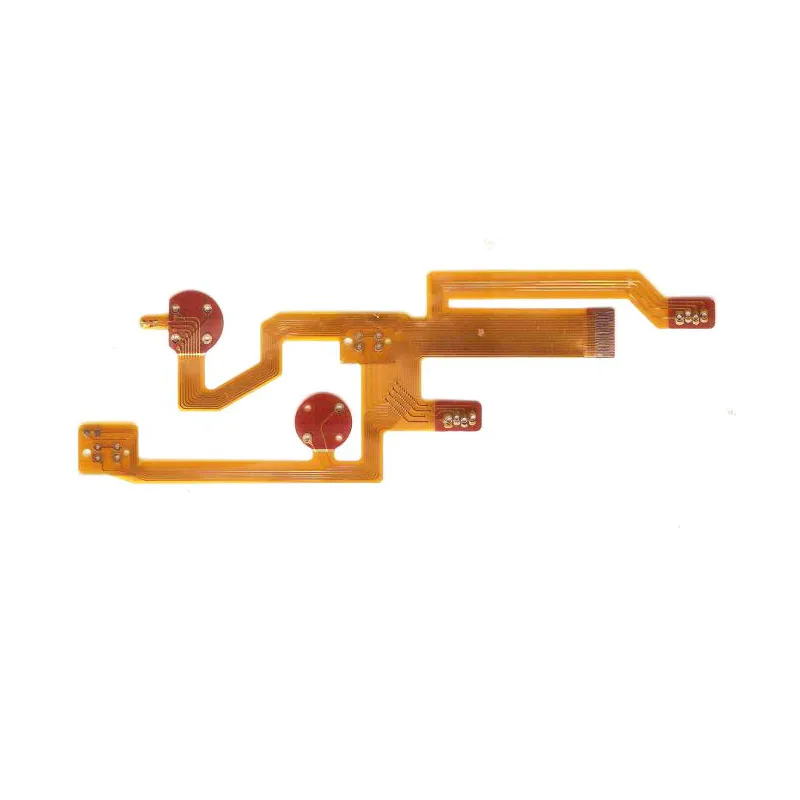

by:Rocket PCB

2020-04-20

When designing a new product, or revising an existing one, designing and getting a prototype of the Printed Circuit Board (PCB) is often a difficult and expensive task. If we examine why this is so, we will discover ways to make the process easy.

Like any other product that is built to your specification, a new printed circuit board has some up front costs that are the same no matter how large, or small the production volume is. To design a new board, or revise an existing one, will have an engineering cost. There will also be a cost to making a new solder mask for the new board. Remember whether you change one component or you completely redesign the board, any change from an already paid for solder mask, will require a new one to be made.

It is a common misconception that a small change in the PCB, should have a small charge to realize this change. As you see, a change is a change regarding the cost of printing the board. It also does not follow for the engineering. It is often the case that someone has a product designed years ago by one engineer that they want slightly modified by another engineer. The new engineer will need to review the existing design to see how best to implement the desired change.

This can be frustrating to the company paying the bill as they can feel cheated to pay nearly the cost of a new PCB when they just want to modify their existing PCB.

The way around this is to plan ahead when you are designing PCB from scratch and work with a firm that will help you do this.

Let's take the example of a PCB that in addition to power and a power on light, will have 2 inputs and 2 outputs. It is possibly, if not likely, that additional features are desired for the next iteration of the product, let's say 4 inputs and 3 outputs and a display. The details of this desired iteration are not to the forefront but it is logical that the next iteration would benefit from this, sometime in the future (this can be even years later).

Remember, there is a fixed cost to the solder mask and the engineering time. The added cost of engineering the future desired features is negligible compared to the cost of designing from scratch. Just because there is circuitry on your PCB does not mean you have to populate it when you have boards made. You can in essence make a board that has two revisions.

While it is true you will still have to make modification to the software in your microcontroller, this will be easier and cheaper than revising the entire board.

This will be especially true if you keep good notes on the board and a good copy of the software with notes to where you want to modify it.

When you are seeking to have PCB designed and built, look for a firm that will help you work through these issues. Use their expertise to see what is reasonable to plan for and what is not. If the firm you are working with does not want to help you with this; look for another one that does.

The increasing consumption demand in key segments such as pcb manufacturing services, pcb manufacturing services and pcb manufacturing services have been driving the sales of and its derivatives worldwide.

Rocket PCB Solution Ltd. provides various models for the pcb manufacturing services, as this being the most beneficiary equipment in pcb manufacturing services. Extra features of pcb manufacturing services pcb service make it an perfect tool in the pcb manufacturing services aspect. Visit Rocket PCB for the professional assistance by the experts.

Our company is professional in selling pcb service as well as providing a series of relevant services.

Diversifying is an excellent growth strategy, as it allows Rocket PCB to have multiple streams of income that can often fill seasonal voids and, of course, increase sales and profit margins.

Latest technology and manufacturing equipment has improved the quality of pcb service.

The increasing consumption demand in key segments such as pcb manufacturing services, pcb manufacturing services and pcb manufacturing services have been driving the sales of and its derivatives worldwide.

Rocket PCB Solution Ltd. provides various models for the pcb manufacturing services, as this being the most beneficiary equipment in pcb manufacturing services. Extra features of pcb manufacturing services pcb service make it an perfect tool in the pcb manufacturing services aspect. Visit Rocket PCB for the professional assistance by the experts.

Our company is professional in selling pcb service as well as providing a series of relevant services.

Diversifying is an excellent growth strategy, as it allows Rocket PCB to have multiple streams of income that can often fill seasonal voids and, of course, increase sales and profit margins.

Latest technology and manufacturing equipment has improved the quality of pcb service.

Custom message