Circuit board vertical two copper wire what are the main reason

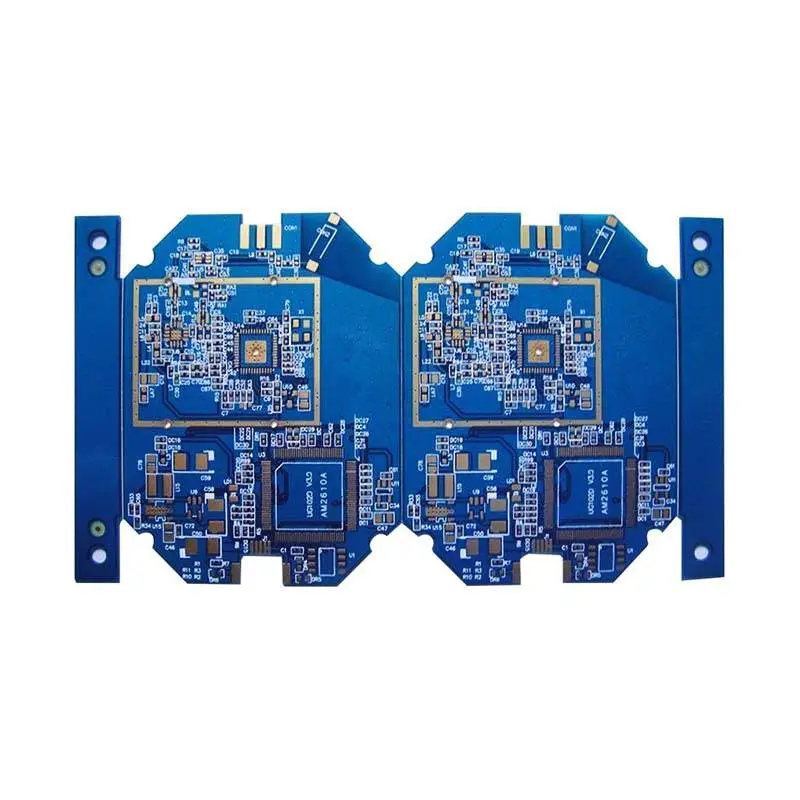

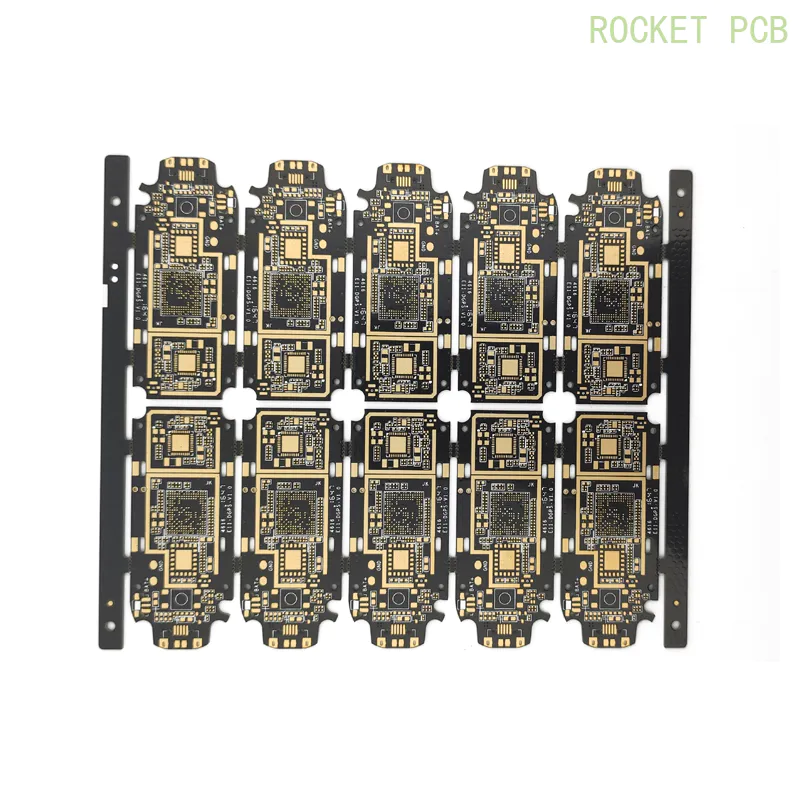

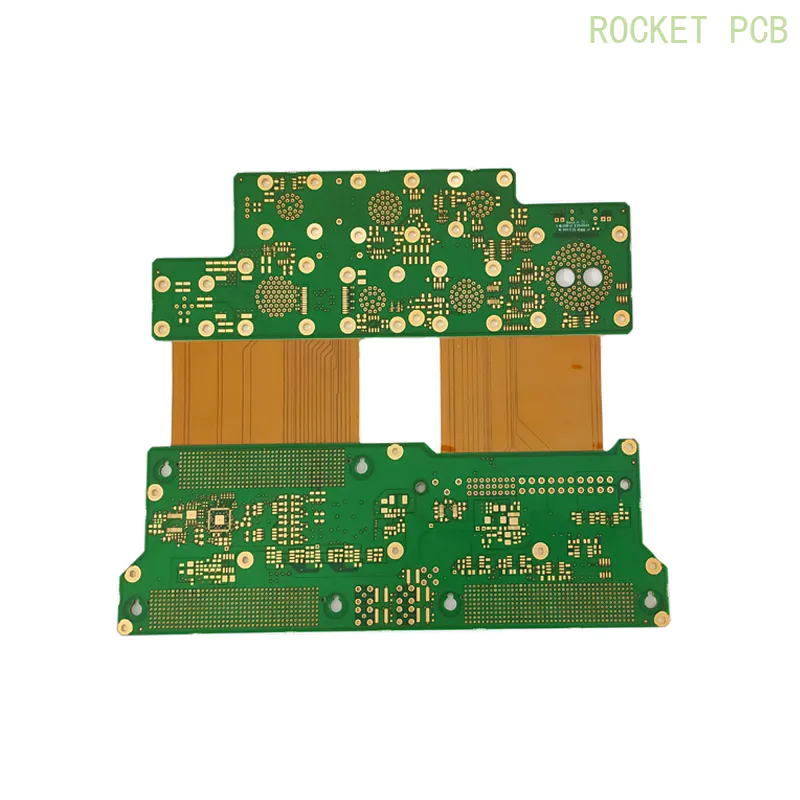

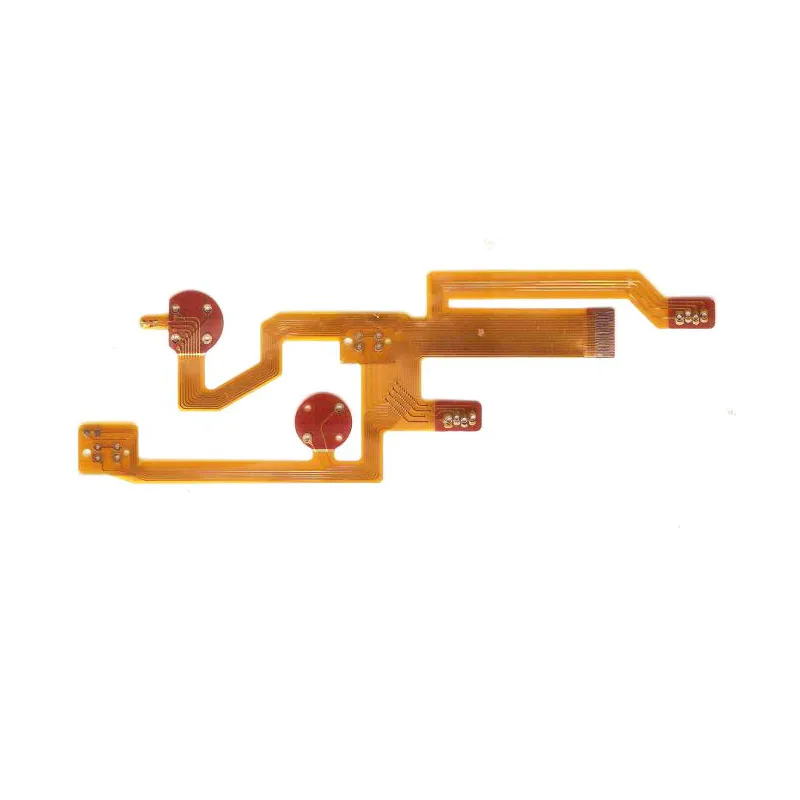

by:Rocket PCB

2020-06-13

Q: can you tell me the circuit board vertical two copper wire of primary and secondary reasons why?

Toward what can be done to improve?

A: circuit board --

A secondary copper wire in the electroplating mostly additive abnormalities or copper tank pollution, as to why pollution sources or yao liquid whether there is a problem, must be your tracking is discussed in detail.

Based on past experience, the secondary circuit board copper plating vertical two copper wire of copper wire together what are the main reason for coating soaked in the liquid, so the dissolution matter more.

Especially from outside, as long as you use a new yao liquid short-term ask quickly becomes angry, this is the result of a light-sensitive membrane stripping phenomenon problem because these substances from the photosensitive material, so easy before and after the dissolution of pleurodesis tank wall is not easy to remove.

If some of these substances polar polymer, are more likely to occur between line jumper plating phenomenon.

According to previous predecessors, points out that this kind of copper wire by slicing inside will not find any foreign body, this is the representative of a copper wire to generate temporary conductive material should be guided, causing subsequent copper grow and connect a line presents the phenomenon, so regular 淸 reason yao liquid at the same time do the wash tank wall residues is necessary to work, I'm afraid.

On a regular basis to make bath, become one of the important methods to prevent this kind of problem.

Unfortunately, so far, no maintenance frequency experience for reference.

Ever have a circuit board factory had suffered a great loss because of this problem, after a period of time to improve will disappear naturally but don't know what to change the problem solved.

Activated carbon treatment was not completely solve the problem, is scrubbing the tank wall, match again there is a significant change, this means that there should be a foreign pollutants interfere with the process.

Now many PCB manufacturers have FTIR analysis equipment with high quality. Suggestions can be yao, water pollution degree, monitoring of organic matter content changes.

Believe that there will still be differences, different yao water system in the past experience or only as a model, the above information is Rocket PCB manufacturer are for reference only.

However, with the increased prevalence of pcb making service, it has become far more affordable.

If you are thinking of having a , then you must be first clear about the purpose, which is driving you to buy this device. Rocket PCB Solution Ltd. offer quality for your needs with complete assurance of ability to serve your purpose.

Rocket PCB Solution Ltd. will give you a suitable price for purchasing pcb making service.

Rewards and discount programs give customers more reason to come back for pcb making service again, especially in the competitive retail and services markets.

Rocket PCB clearly and succinctly expresses what our company is all about. Strong brands cut through the noise to grab the audience and immediately shed light on the character of the product or service.

However, with the increased prevalence of pcb making service, it has become far more affordable.

If you are thinking of having a , then you must be first clear about the purpose, which is driving you to buy this device. Rocket PCB Solution Ltd. offer quality for your needs with complete assurance of ability to serve your purpose.

Rocket PCB Solution Ltd. will give you a suitable price for purchasing pcb making service.

Rewards and discount programs give customers more reason to come back for pcb making service again, especially in the competitive retail and services markets.

Rocket PCB clearly and succinctly expresses what our company is all about. Strong brands cut through the noise to grab the audience and immediately shed light on the character of the product or service.

Custom message