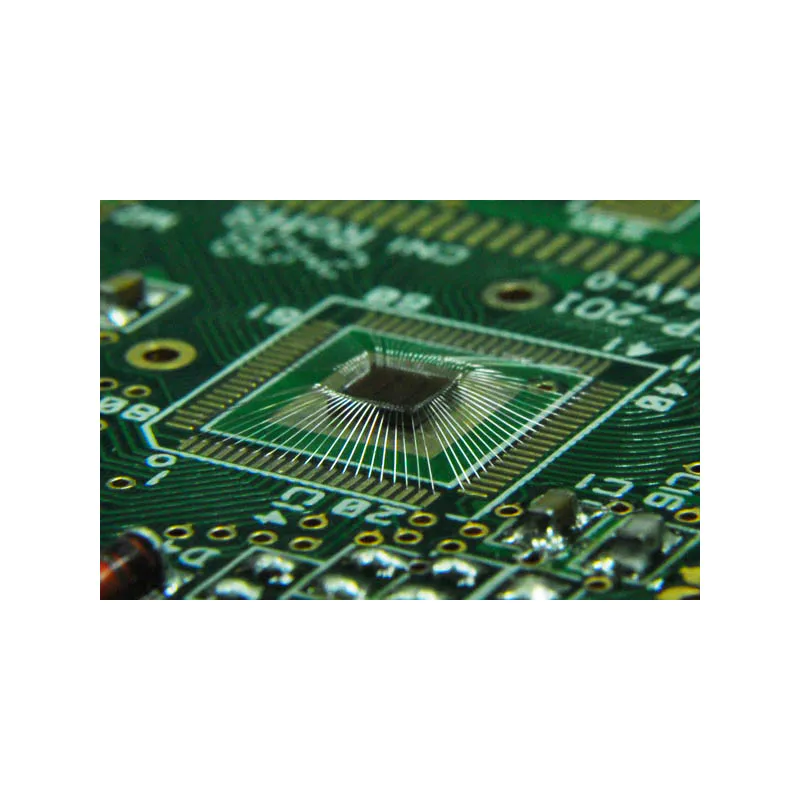

Circuit board under the PCB after automatic tin furnace line insulation green paint peeling off

by:Rocket PCB

2020-06-13

After boards in automatic tin stove, beneath the plate line insulation green paint peeling off.

I don't know are the reasons?

After the king S/M Peeling and because what reason?

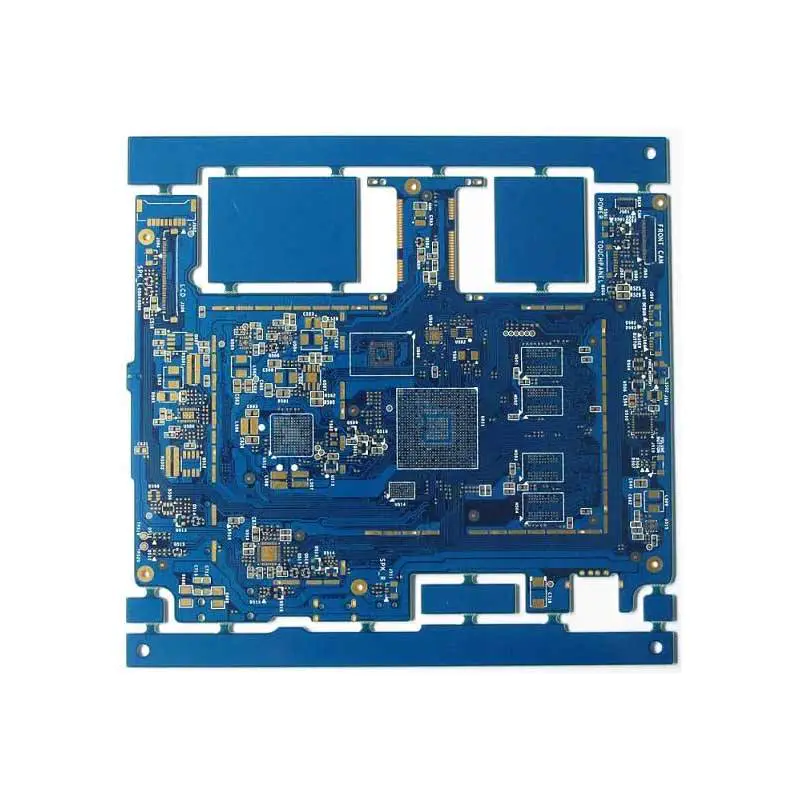

Circuit board (

PCB board)

Green paint falls off has the following three larger possibility 1, circuit boards,

PCB board)

Nature is green paint itself is not enough to withstand test of the stove, it might be green paint is expired or bad operation nature.

Almost all companies use the green paint to heat, such as reliability test program, so problems should not be the norm, this aspect should review the material itself to see if there is change or process change.

2, may be because of the influence of the external force, including flux supply and mechanical collision etc. , especially under the condition of high temperature no longer green paint features like environment with high hardness under normal temperature, the circuit board of the green paint by any external shocks are easy to produce scrape peeling off.

3, the larger possibility is that the circuit board (

PCB board)

Or in front of the green paint coating caused by moisture when stored in blowout, vapour when heated vaporization volume expanding is nearly three hundred times, instant heating with green paint to soften, very easy to produce green paint peeling off.

This kind of problem in the tin of PCB production process will appear, may also occur in wave soldering, welding assembly process, such as back.

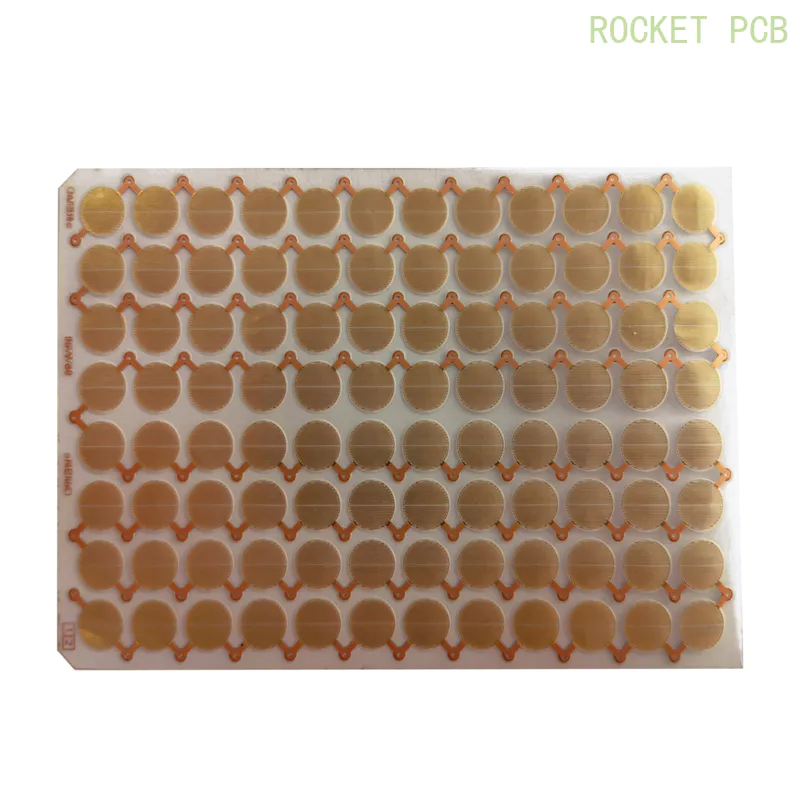

Circuit board under the PCB after automatic tin furnace line insulation green paint peeling off board (

PCB board)

SMPEELING after the gold has the following six before May 1, may be copper processing not ideal 2, may be out of S/M before coating drying 3, may be stagnant time is too long to produce oxide layer 4, may be the material of green paint itself is not suitable for the poor gold cheng 5, may be green paint polymerization degree is less than 6, if you do too much in the high temperature of more than one process, such as: gold and gold-plated or two gold leaching, is also likely to occur.

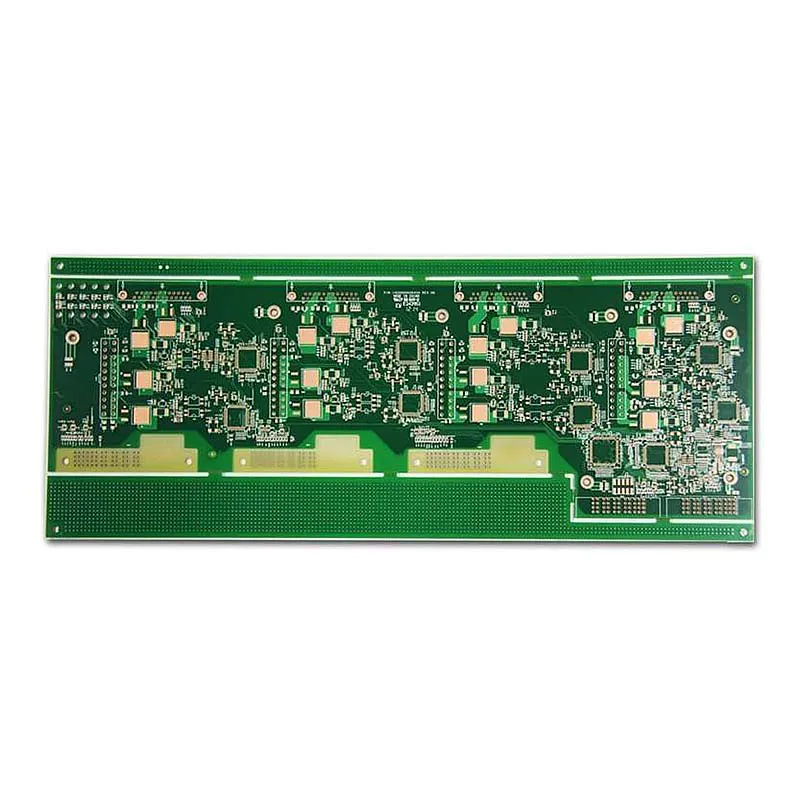

Detailed analysis possibility because of the many you must do the item by item, to clarify, but in general use for S/M type is quite important.

Some special green paint, responses to UV light slow, anaerobic and relatively high exposure energy is needed to achieve a high degree of polymerization.

If the exposure degree of polymerization is insufficient, the follow-up baking, there is no way to completely achieve aggregation intensity.

If you use this kind of material, the correct processing method, the operator should be clearly informed otherwise problem constantly, the above for your reference.

Rocket PCB Solution Ltd. as one who also teaches operations about how we use our whole operating system as a way to gain advantage and create considerable value and capture value in a sector where, in essence, the environment is quite hostile from a competitive point of view.

All of the experts Rocket PCB Solution Ltd. consulted stressed that the best recovery plans are the ones made before you need them, not afterward.

Increasing consumer awareness and rising concern about improving pcb manufacturing services are driving the market of products.

Rocket PCB Solution Ltd. as one who also teaches operations about how we use our whole operating system as a way to gain advantage and create considerable value and capture value in a sector where, in essence, the environment is quite hostile from a competitive point of view.

All of the experts Rocket PCB Solution Ltd. consulted stressed that the best recovery plans are the ones made before you need them, not afterward.

Increasing consumer awareness and rising concern about improving pcb manufacturing services are driving the market of products.

Custom message