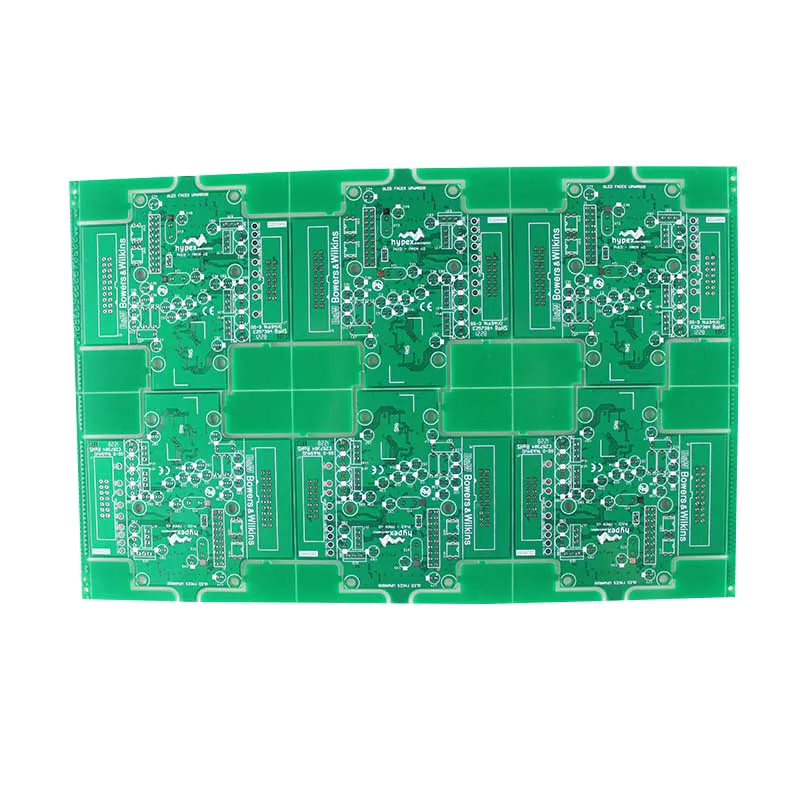

Circuit board factory quality inspection, let the customer trust of inspection standard

by:Rocket PCB

2020-06-14

Mention the product quality inspection, believe that we almost always think (

Printed circuit board)

Processing and manufacturing, Rocket PCB small make up today to share is about dongguan circuit board factory some related issues of PCB quality inspection, interested friends can have a look.

Poor quality available, good, master adjectives modify.

Features may be inherent or, given by the qualitative or quantitative;

Category has the characteristic of physical

Such as mechanical, electrical, chemical, or biological characteristics)

, sensory,

Such as the sense of smell, touch, taste, vision, hearing)

, behavior (

Such as politeness, honesty, integrity)

That time,

Such as punctuality, reliability, service life)

, the function of (

As the aircraft's flight altitude, flight speed)

, so the quality of our circuit board factory to how to handle?

What are the function and meaning?

PCB circuit board manufacturers of quality management of the development process has experienced three stages, namely the quality inspection management stage, stage of statistical quality management, total quality management stage.

Quality inspection is by means of early in quality management, and in the future continue to apply in a variety of quality management and continuous completely.

In the current quality management system still need to quality inspection.

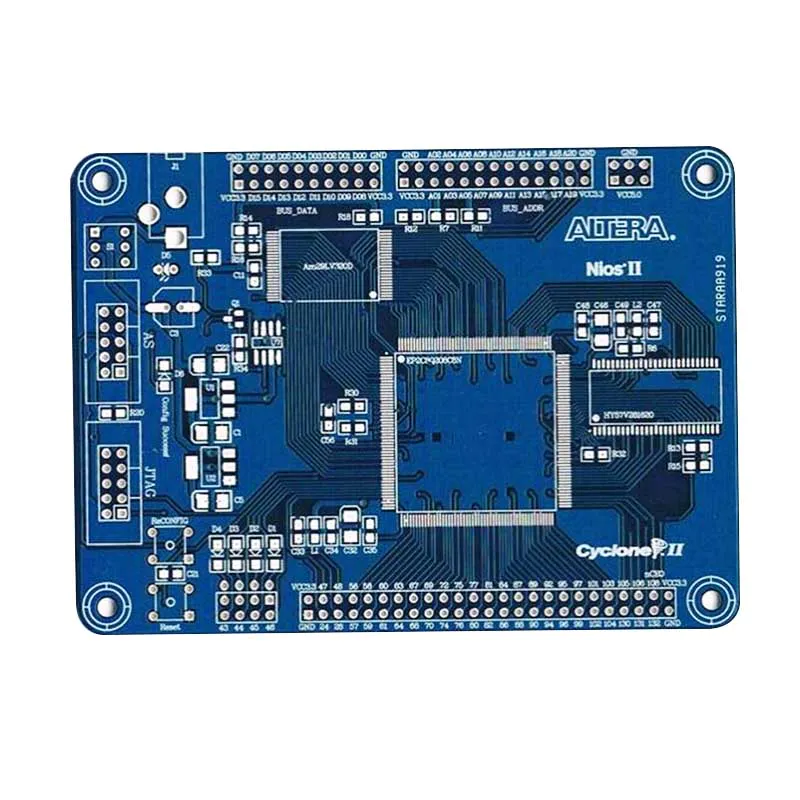

Printed circuit board/circuit board production is designed and manufactured product quality, is not a test, but the quality inspection is an important factor of the quality system, in the modern quality management, quality inspection also plays a very important role.

The formation of the product quality due to the staff, machine, material, method, environment and other subjective and objective factors, is a complex process fluctuation process of contact, the quality of the product change is inevitable.

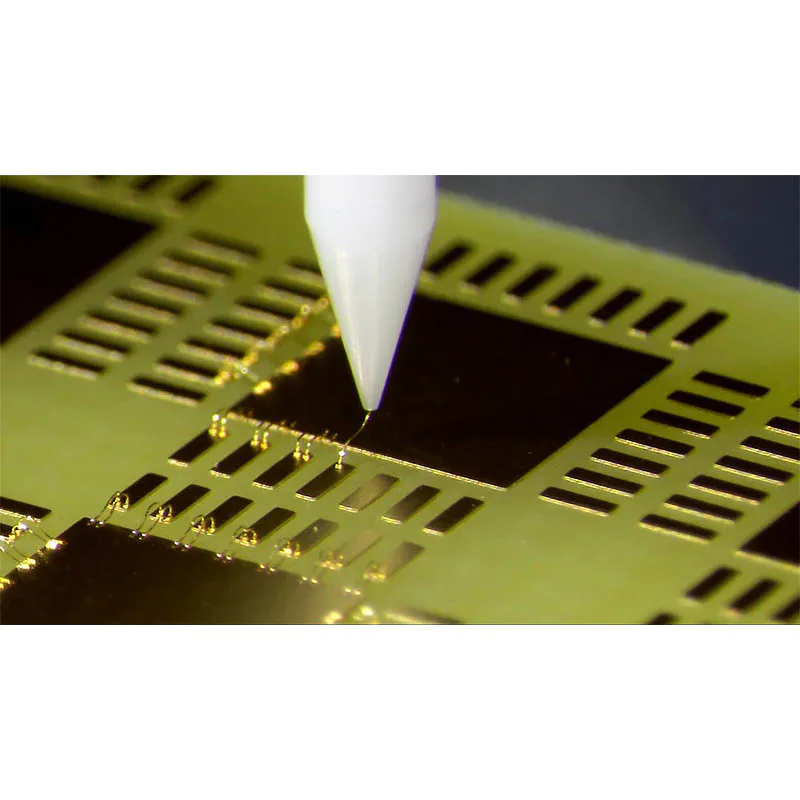

So in the production process of each link or each working procedure, must be the quality inspection.

According to the different stages of product realization process, quality inspection is divided into three basic types: incoming inspection, process inspection and final inspection, of course we have a final inspection PCB circuit board manufacturers.

(

1)

Incoming inspection for raw materials, auxiliary materials, outsourcing parts and purchased parts into the plant receiving inspection before storage.

Do not put in storage, do not use unqualified material.

(

2)

Process inspection: also calls the process inspection, the production site in products inspection in the process of production.

Avoid unqualified products into the next working procedure, and prevent abnormal mass failure in production process.

(

3)

Final inspection: also known as the finished product inspection, finished product in the storage and delivery of completed before test.

The inspection is completely according to the customer's contract and relevant standards, to ensure that customers receive.

Above about PCB/PCB factory the quality inspection of some introduced here, and control system is according to the process of PCB factory, if want to know more information or need to do for PCB circuit board customers friends please consult dongguan Rocket PCB manufacturers

The importance of pcb making service has increased as pcb manufacturing services have become a must in our daily life.

Exceed customers' expectations in the procedures of manufacturing pcb making service.

It is never too late to have a new mindset and to get things moving in the right direction. Choose Rocket PCB Solution Ltd. to be your quality provider.

pcb making service can also provide a new, productive option for business owners, if you're willing to use it.

The importance of pcb making service has increased as pcb manufacturing services have become a must in our daily life.

Exceed customers' expectations in the procedures of manufacturing pcb making service.

It is never too late to have a new mindset and to get things moving in the right direction. Choose Rocket PCB Solution Ltd. to be your quality provider.

pcb making service can also provide a new, productive option for business owners, if you're willing to use it.

Custom message