Circuit board factory: PCB JiaGongDian gold-plated layer were black

by:Rocket PCB

2020-06-17

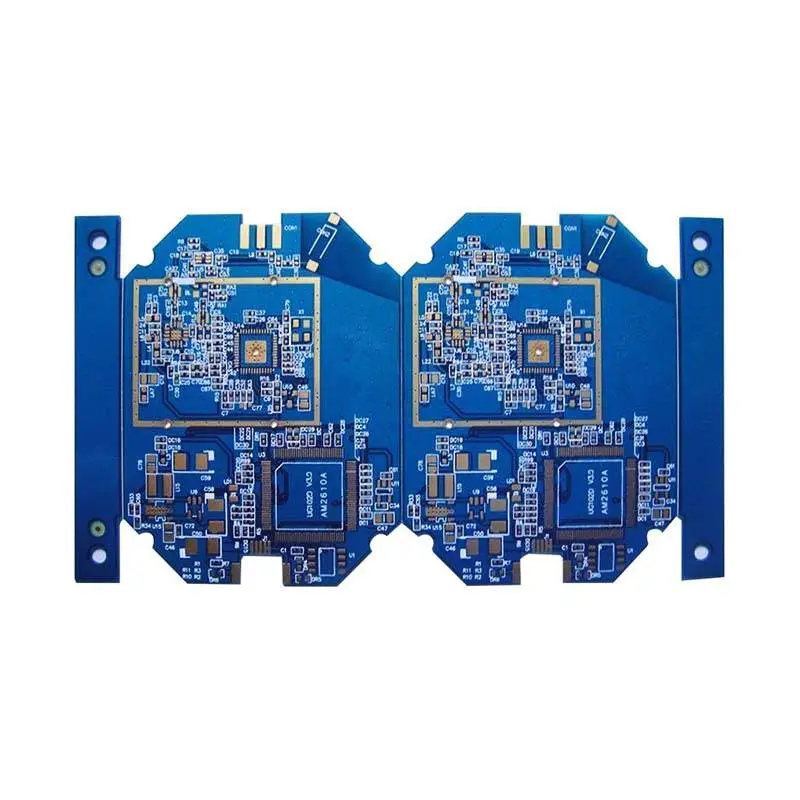

Recently received peer E - dongguan circuit board factory

Mail contact QQ, when it comes to the problem of electric plating layer black reason and solution.

Due to the actual PCB factory production line, equipment used, the potion system is not the same.

Therefore need to analysis and disposal of products and the actual situation to solve.

Here is only about three general common cause problems for your reference.

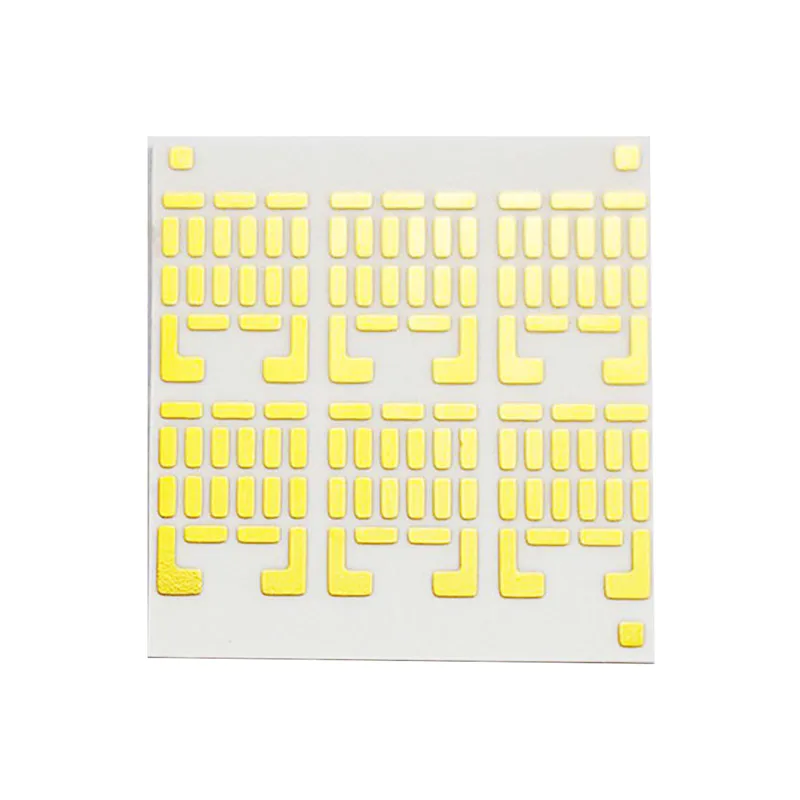

1, PCB plating nickel layer thickness control everyone must think small make up dizzy, said electric plating layer black problem, how can say to the nickel plating layer thickness.

Actually PCB circuit board electric plating layer is generally thin, reflect a lot on the surface of electric plating problem is caused due to the poor performance of plating nickel.

Common electroplating nickel layer slants thin cause product appearance will be white and black.

So this is the preferred plant engineering and technical personnel to check the project.

Generally need to about 5 um nickel plating layer thickness is enough.

Dongguan circuit board factory 2, the condition of the potion of electroplating nickel cylinder or cylinder to nickel.

If the potion of nickel cylinder can not get good maintenance for a long time, not in a timely manner carbon processing, plating of nickel layer would be prone to flaky crystal, increase the coating hardness and brittleness.

Serious will produce black coating problems.

This is a lot of people are easy to overlook the control point.

Also often is the important reason of the problem.

So please check carefully your potion status of PCB factory production lines and comparative analysis, and a thorough carbon treatment in time, to restore the potion activity and clean of the plating solution.

(

If not a carbon that is more big)

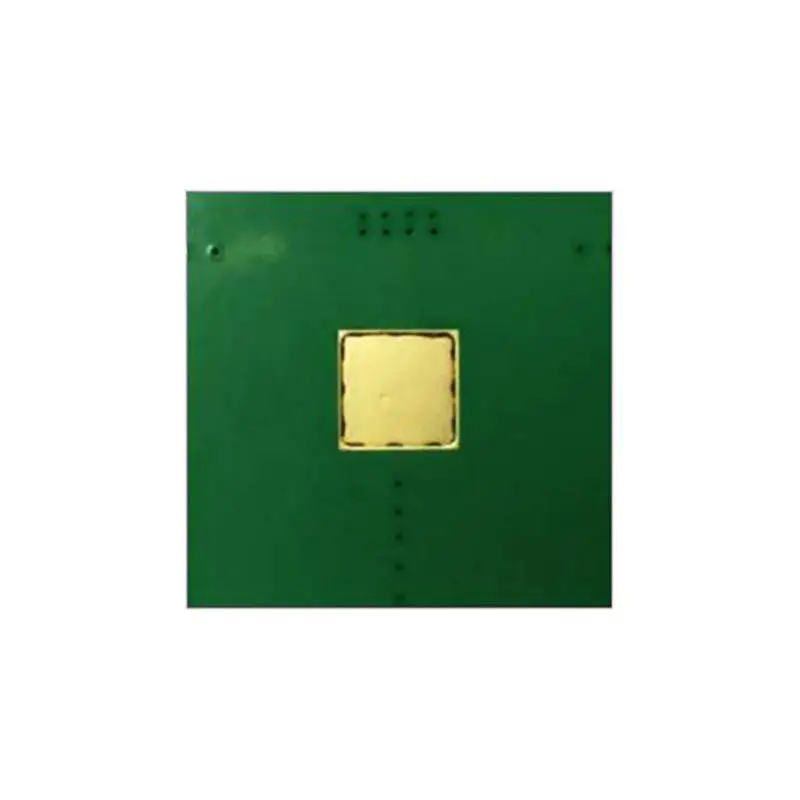

3 control now is the gold, gold cylinder cylinder control.

Generally if keep good potions filtering and complement, as long as the contaminated degree of gold cylinder and stability than the nickel cylinder will be better.

But need to pay attention to check whether the following several aspects: (

1)

Gold cylinder supplements to add enough and too much?

(

2)

PCB processing liquid PH control situation how?

(

3)

Conductive salt?

If the result is no problem, and then use the AA machine analysis analysis of impurities in the solution.

Margin cylinder of liquid state.

Finally, don't forget to check the gold cylinder filter cotton core is haven't change for a long time.

If it is, but you can't control strictly.

Still not quick to change.

Rocket PCB Solution Ltd. is one of the most-trusted manufacturing suppliers to the domestic markets.

Rocket PCB Solution Ltd.’s sole aim is to provide exquisite and unheard of features to the concept of producing technology.

It's the consistent experience that builds trust and loyalty. Creating a personality and platform that is scalable will allow you to evolve pcb making service with your consumers.

Rocket PCB Solution Ltd. is one of the most-trusted manufacturing suppliers to the domestic markets.

Rocket PCB Solution Ltd.’s sole aim is to provide exquisite and unheard of features to the concept of producing technology.

It's the consistent experience that builds trust and loyalty. Creating a personality and platform that is scalable will allow you to evolve pcb making service with your consumers.

Custom message