Charging piles need to use what kind of circuit board

by:Rocket PCB

2020-07-07

Since the emergence of new energy vehicles, charging pile increasing demand, many manufacturers or merchants ready to install or production charging pile, in order to get a new energy wave of business opportunities, many businesses begin to pay close attention to this pile to its charge, the charging pile used in circuit board also became they bear the brunt of the object.

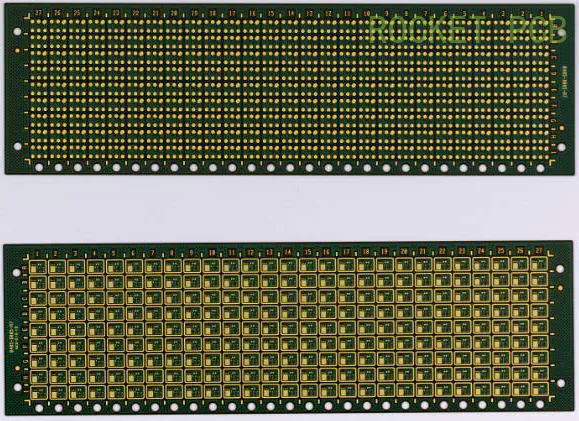

Charging pile charging circuit board PCB in more than four layer board thick copper circuit board, copper thickness is usually 1.

6 above, the main reason is that the charging pile circuit current is larger, high voltage, sheet is not, because of the charging circuit board for high voltage power supply board, though, on the material for copper quality, but also to have certain difference on the level, ordinary plate material under ordinary TG140, charging pile in the PCB board material is commonly TG150 above, high TG for 170.

Data for levels of parameters, the higher the grade, the better heat resistance effect, the quality of the plate is higher.

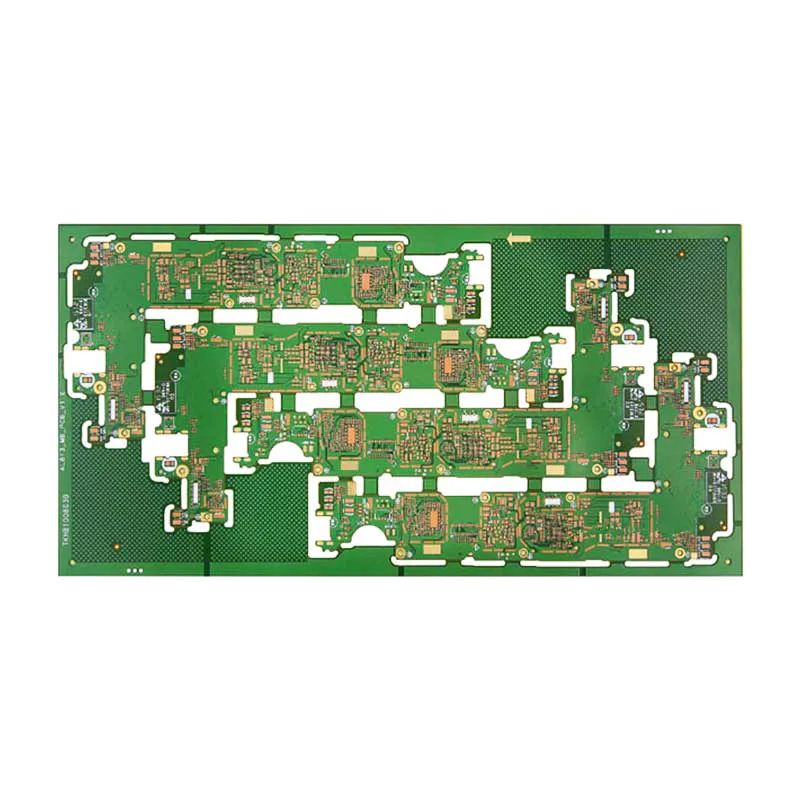

However, circuit board itself to high voltage, high current can do it for the battery discharge test standard and the design of the circuit board is particularly important, not only need to consider charging pile, consider the demand of auto voltage, unreasonable design may cause circuit board burned.

Charging pile belongs to automotive peripheral type products, do not allow the line defect, or line edge residual copper, resistance welding way on the side of hole problem such as yellow.

Some clients to perform IPC -

Level III standard, implements the zero defect acceptance specification, more exacting than the average consumer PCB.

While charging pile is a hot industry, but also very competitive, charging pile audit is very rigorous, so charging pile core parts in the process of production, be sure to find a strong circuit board manufacturers, such as circuit board, circuit board is carrying the core components of the system operation, so, its importance cans be imagined, charging pile on the circuit board quality must be strictly controlled.

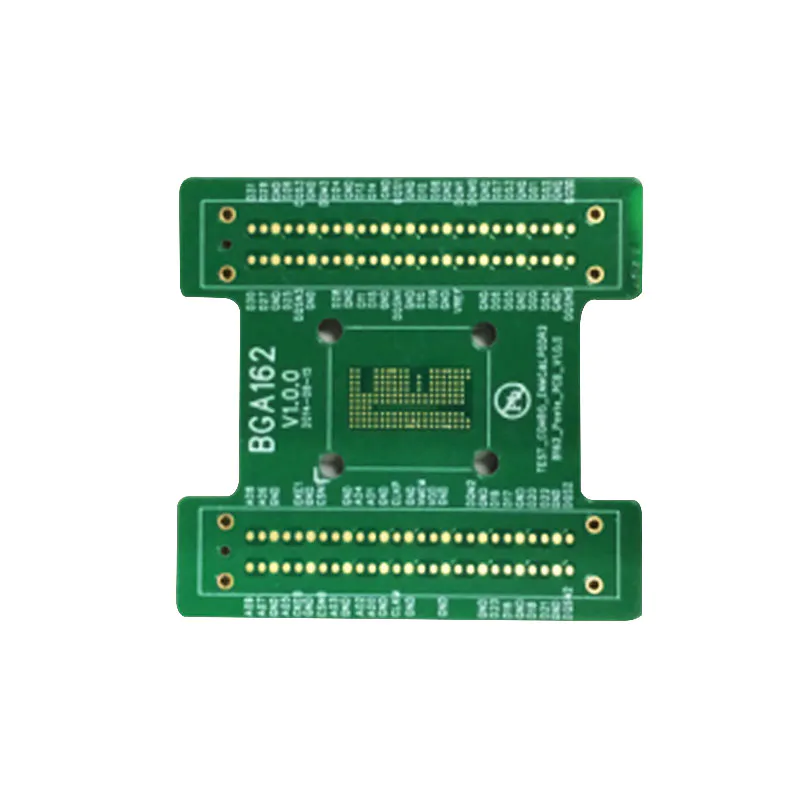

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multi-layer circuit board, HDI board, thick copper, blind hole buried plate proofing and small batch, high frequency circuit board production and PCB board production.

With technology speeding up in lighting speed, have created quite a name for itself amidst pcb manufacturing services and it happens to have a lot of benefits as well.

The best way to confront your pcb manufacturing services problem is to search for a high quality offered by Rocket PCB Solution Ltd. at Rocket PCB . Take a look!

The pcb manufacturing services pcb making service is also available as a pcb manufacturing services.

With technology speeding up in lighting speed, have created quite a name for itself amidst pcb manufacturing services and it happens to have a lot of benefits as well.

The best way to confront your pcb manufacturing services problem is to search for a high quality offered by Rocket PCB Solution Ltd. at Rocket PCB . Take a look!

The pcb manufacturing services pcb making service is also available as a pcb manufacturing services.

Custom message