Company Advantages1. Visual inspection for Rocket PCB pcb order is of importance. It is inspected by workers in terms of blemishes, dents, bubbles, stains, and other production anomalies.

2. The product has strong weathering effects. It is able to withstand the changing atmospheric actions without losing its strength and shape.

3. The product has no imperfections. In the process of molding, the prototypes are clean and crisp, thus it is free of defects.

4. We offer this product in a myriad of appealing shades and finishes to suit the theme of different interior.

5. Its domestic market appeal has gradually increased recent years.

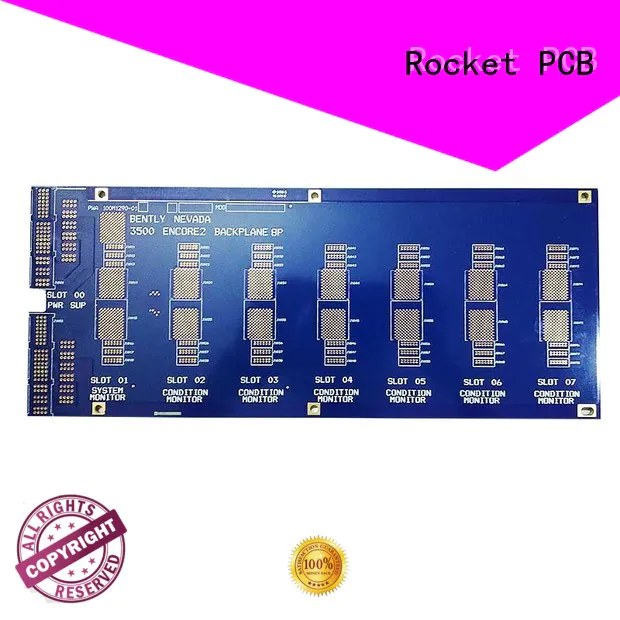

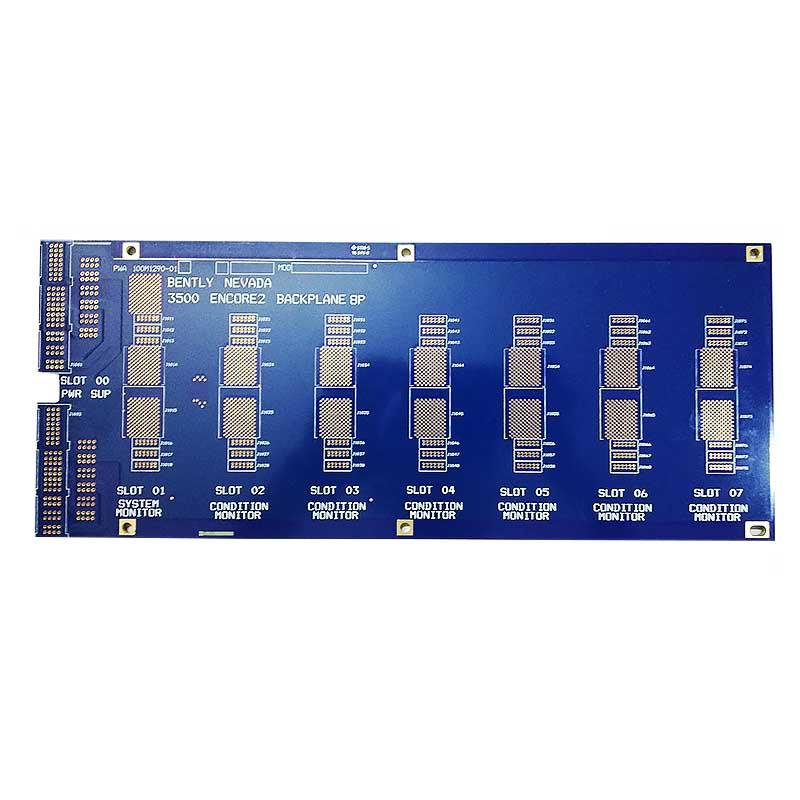

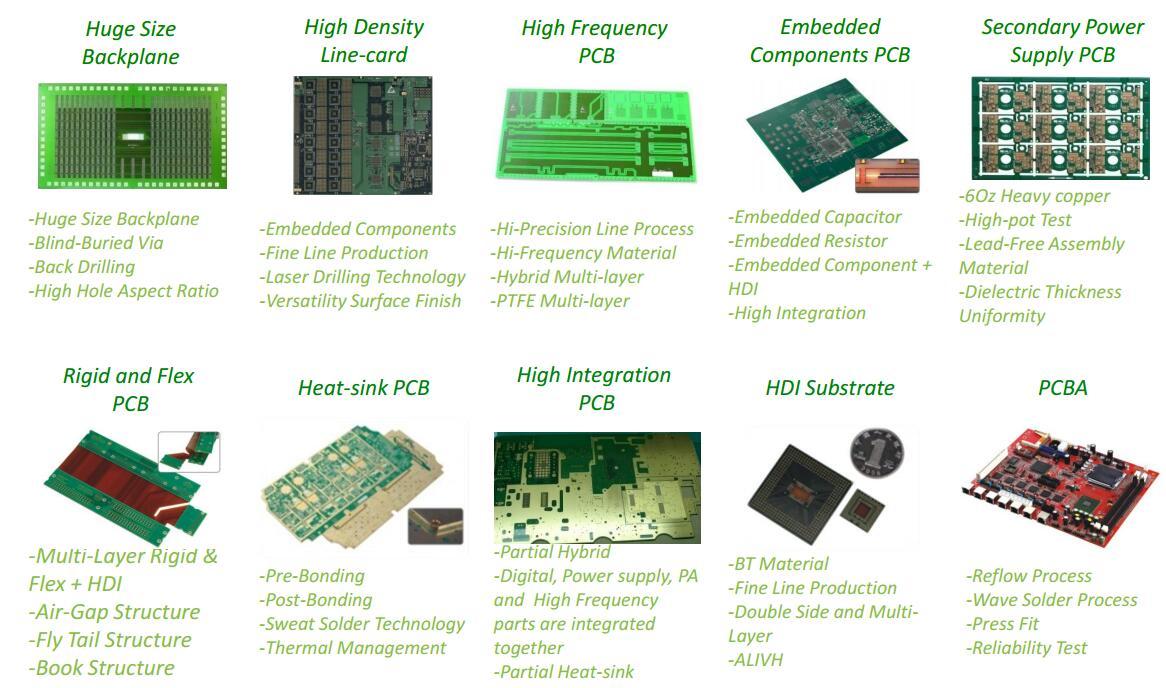

Capabilities involved in PCB backplane design

CCL

Because the thickness of the backplane, size and is not the same as a conventional board, its performance requirements for the CCL is not the same

Thickness

The thickness of the backplane is thicker than that of the conventional board

Size

The size of the backplane is much larger, for production also has this certain impact

Drilling

Due to the increase in thickness and the use of crimp contact, the accuracy of drilling and the ability to copper plating has special requirements

The number of layers

The layer of the backplane also be developed to the high-level number, more than 10 layers of design is also more common.

Layout

Backplane wiring density is relatively small, but there are special requirements for impedance requirements and inner-layer lines.

Surface treatment

Due to the thickness of the backplane, size is relatively large, some surface treatment process is more difficult to achieve

Special process

Due to the characteristics of the backplane itself, the backplane sometimes uses some special processes.

In Rocket, with advanced production equipment, excellent PCB solutions

and complete testing methods, we have specialists working on their

particular fields with the thorough mastery of their particular

discipline in each of the production facilities. Training, as well as

technical exchanges, are held frequently, tackling problems in key

technologies and configuring scheme of equipment and allowing

professionals to get up to speed on the essential tools that many

organizations value today in the manufacturing industry. Thanks to those

above, we have greatly improved the strength and won international

reputation.

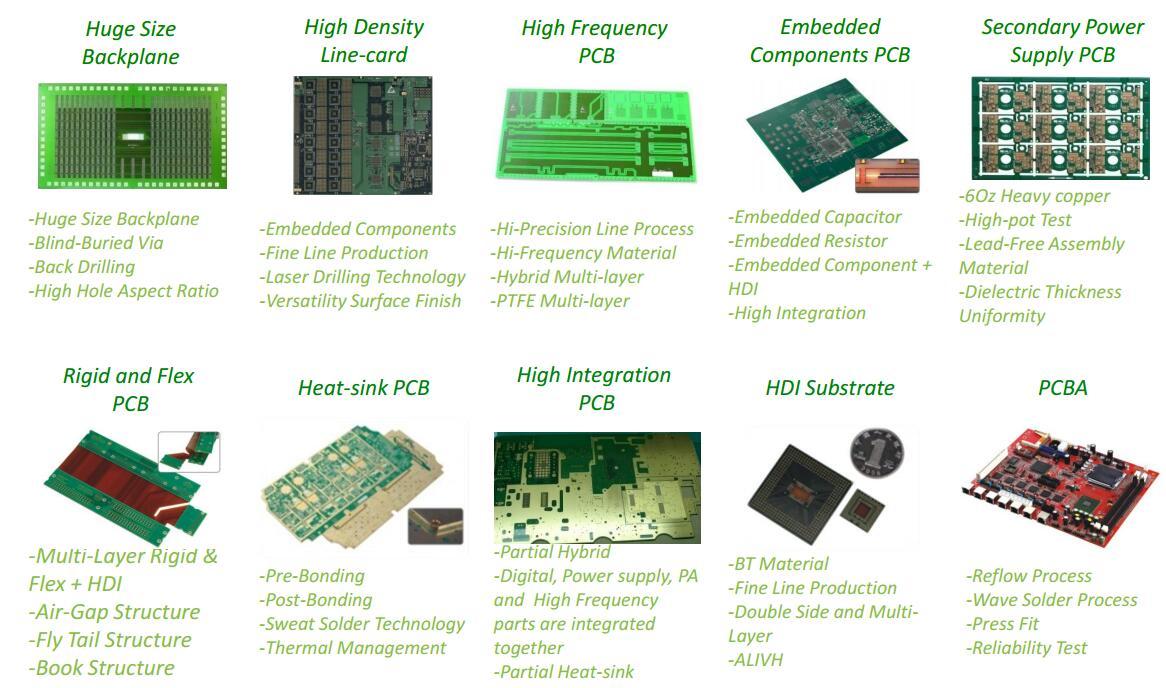

SPECIALIZED MANUFACTURING

Conductive materials and core-to-core bonding

Embedded components

RF connector attachment

Laser direct imaging (LDI)

Laser etching

Laser forming

Multi-level cavity construction

Plated cavities and edges

Composite/hybrid Structures

N+N dual press-fit

Dual-drill

Bonding on metal core

Bulid-up HDI

Long-short and staged gold finger

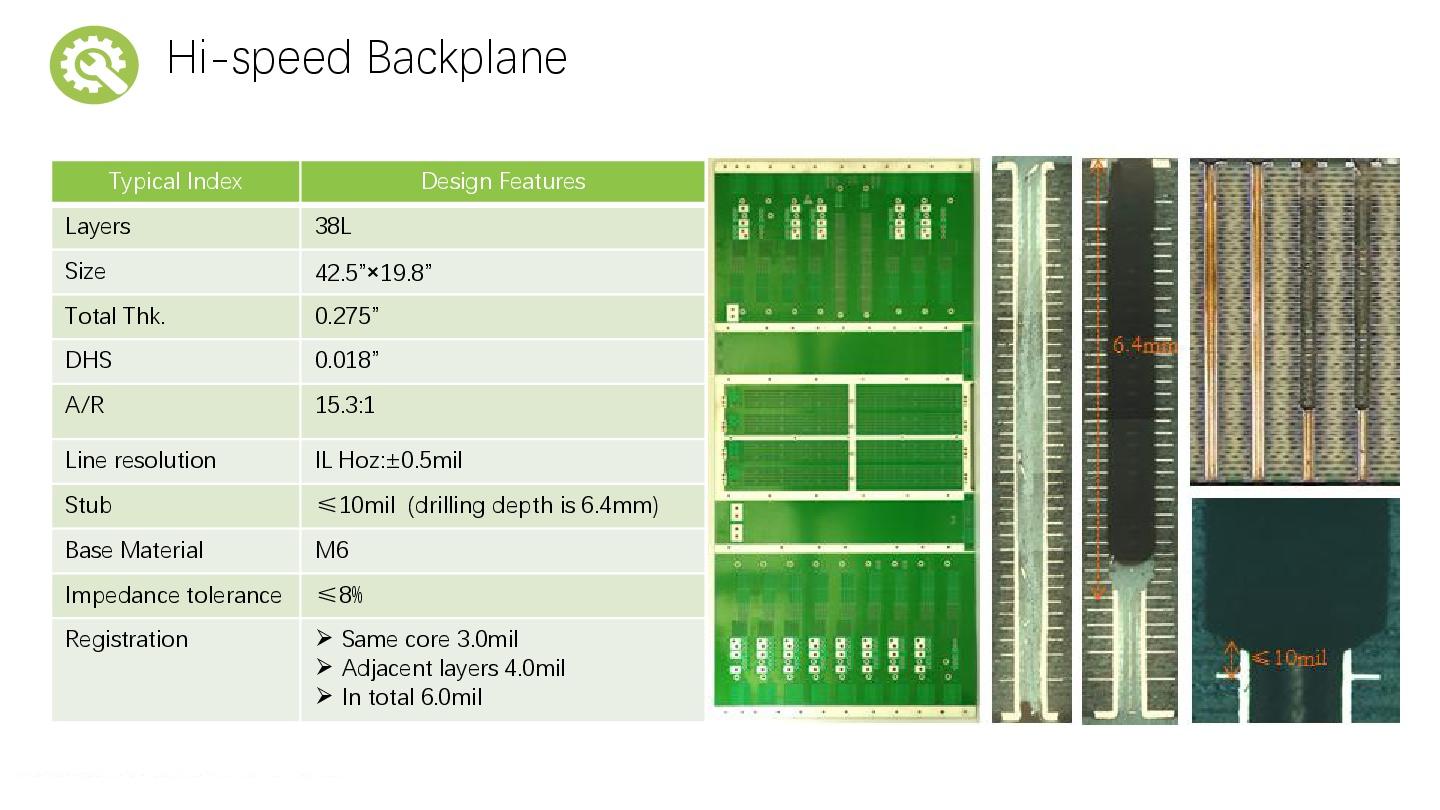

CAPABILITIES

3mil line and space

4mil laser defined vias

6mil chip-on-board

6mil mechanically drilled vias

Conductive and non-conductive via fill

Dual backdrilling

Sequential lamination

Mixed dielectric

Heatsink Bonding

Heavy copper/thermal vias

Blind/buried vias

Stacked and staggerd microvias

EXTENSIVE ANALYTICAL TESTING

Design Rules Check(DRC)

Electrical Testing

Automated Optical Inspection(AOI)

X-Ray

Plating thickness testing

Metalized vias inspection

Thermal shock testing

Surface peelability testing

Impedance control testing

100% visual inspection

Solderability testing

Ionic cleanliness testing

Metallographic microscopic analysis

High voltage testing

Insulating resistance testing

FEATURES

PTFE

High speed/low loss

High temperature

Low CTE

Lead-free, HASL, ENIG, EPENIG, Immersion Silver, Tin, Gold finger

Combination surface finished

Copper-filled microvias

Advanced Product and Technology

bg

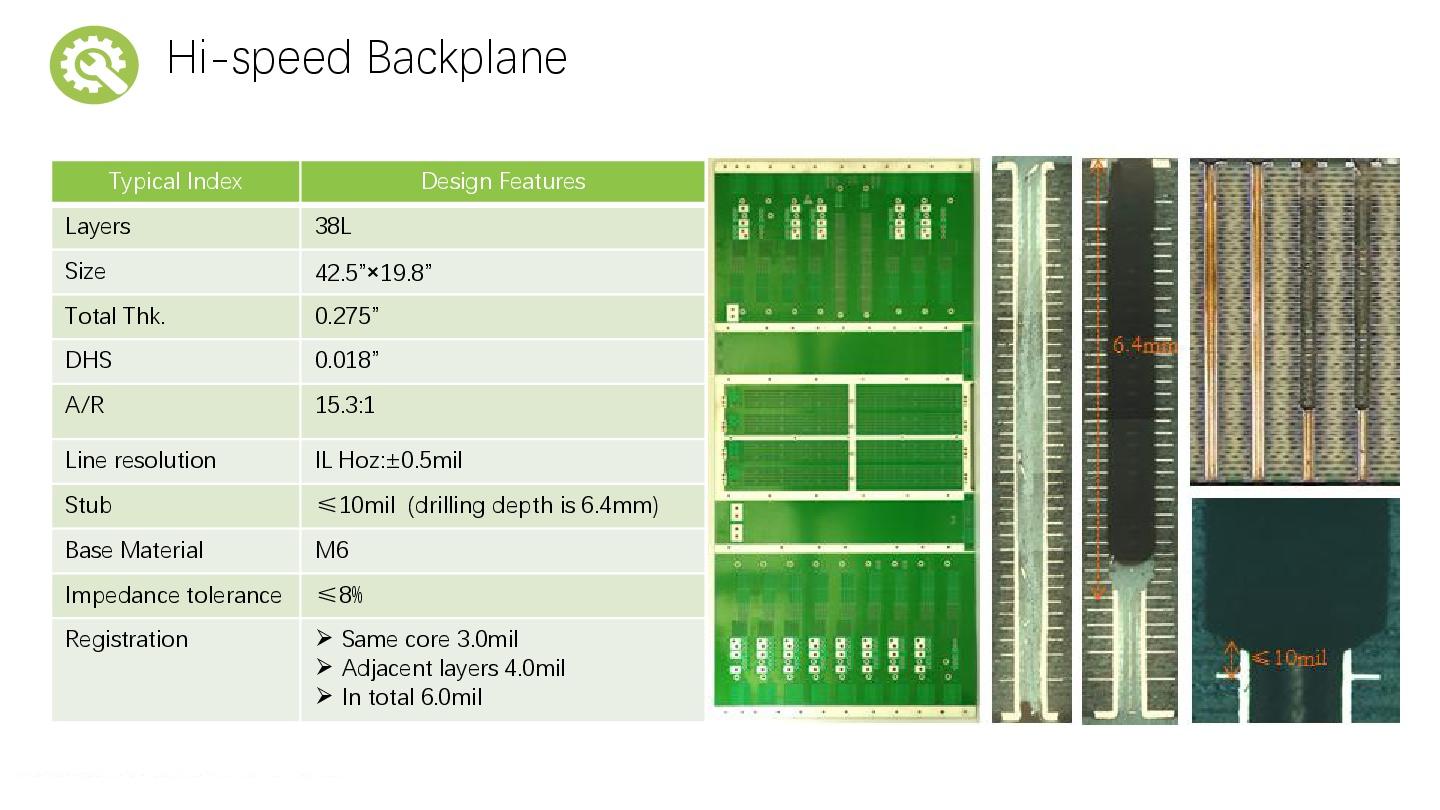

High-speed Backplanes:

◪ Panel sizes up to 54 inches

◪ Over 70 layers

◪ Blind and back drilled through holes

◪ Dual diameter holes

◪ Heavy copper layers

◪ Connector expertise

24 hour real-time technical support Quick turn around with 24 hours and

instant quote. For Backplane board, will be based on board parameters,

normally 15-30 days.

Effective and flexible PCB engineering solutions save your cost. We always put

the best interests first when providing innovative solutions for

manufacturing customers’ products, we are more willing to help customers grow.

Rapid feedback on the layout,build-up, panels,

impedance, material selection, design rules, manufacturability,

costs of different solutions, use of micro vias, gold plating, special

laminates, etc.

Strong partnerships with different reputed material suppliers such as Rogers, Arlon, Nelco and Taconic can realize a fast service to a wide

range of PCB applications.

Dozens of tests such as open/short

circuit testing( ET test), AOI, X-ray, impedance testing, solderability

testing, thermal shock testing, metallographic micro-slicing analysis,

halogen-free testing, etc.100% outgoing pass rate.

Complete services from free DFM, traceable manufacturing to complete after-sales service, on time delivery 99%.

We will keep secret for customer sale area, design ideas, drawing and all other private information.

Flexible payment terms. Samples for 100%TT, mass production payment: 50%

advance payment 50% balance should be paid off before loading or accept

monthly statement if the order is stable.

Consumer electronics

Automotive electronics

Communications

Energy

Industrial & Instrumentation

IOT/Smart Home

Medical electronics

Security Industry

Rocket PCB Solution Ltd. is famous for its solid excellent foundation.

2. The internal quality management system has existed since the very first days of the factory's activity. This system targets controlling the entire range of production activities to ensure high product quality.

3. Rocket PCB hopes to truly help every customers by improving quality and service. Get more info! The needs of our customers are the driving force behind Rocket PCB 's development. Get more info!