And the types of the short circuit PCB circuit boards common inspection method

by:Rocket PCB

2020-07-23

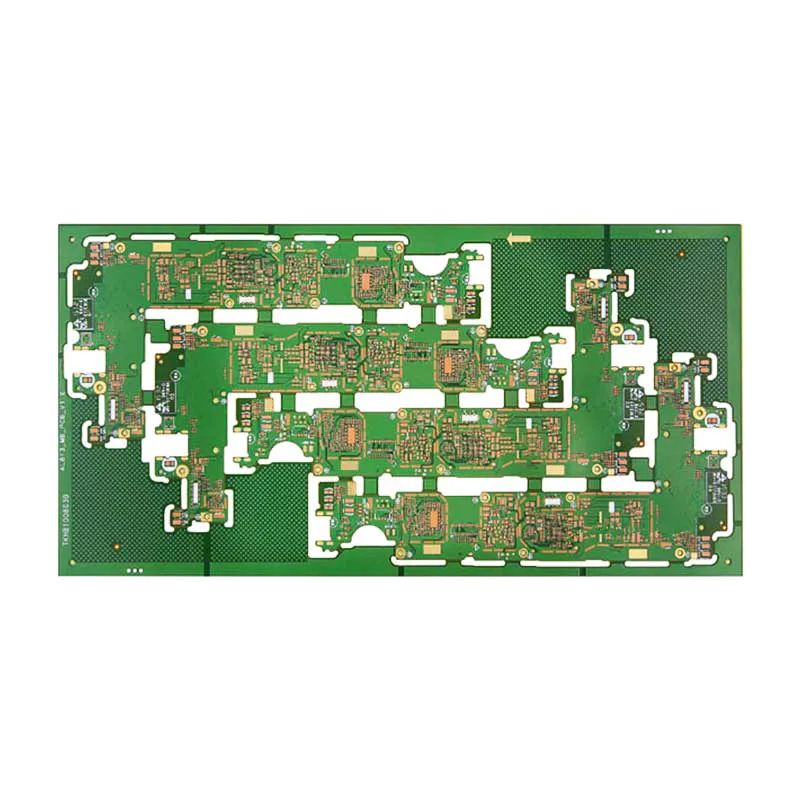

PCB circuit board short circuit is very common in the production of circuit boards.

A short circuit there are generally two kinds of circumstances, one kind is the use of the PCB board has reached a certain fixed number of year.

The second case is in the production of PCB circuit board inspection work does not reach the designated position, etc.

But these small errors in the circuit board production, may cause components to burn out, is very big to the harm of the PCB, is likely to cause scrap.

Therefore in the process of production for inspection and control becomes more important.

So what are the types of short circuit common PCB?

PCB circuit boards production circuit board short circuit check the place where we need to pay attention to what?

A circuit board, common short-circuit the type 1, short circuit according to the functional can be divided into: welding short circuit (

Such as: tin)

, PCB circuit board short circuit (

Such as: copper residue, hole deviation, etc. )

Inner micro short circuit, circuit boards, device breakdown and short circuit, short circuit assembly, ESD/EOS electrochemical short circuit (

Such as chemical residues, electromigration)

, other causes of short circuit.

2, a short circuit can be classified as: according to the wiring characteristics across the line to line short circuit, line (

Layer)

Short circuit, face to face,

Layer on layer)

Short circuit.

Need to pay attention to these points, circuit board short circuit inspection 1, computer open the PCB design, light the short circuit of the network, and see where is the nearest and the most easy to connect to a piece.

Special attention should be paid to IC internal short circuit.

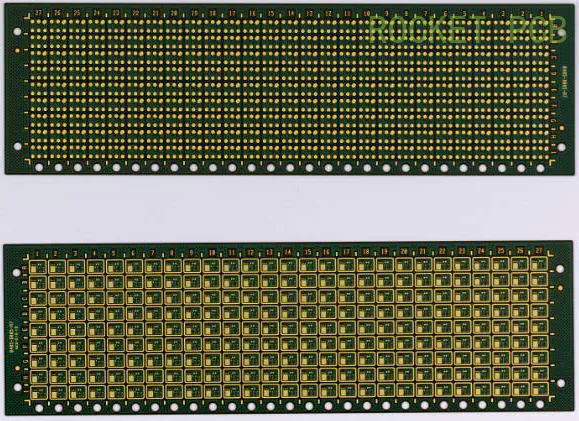

PCB circuit boards,

Double panel)

2, if it is a manual welding, to develop good habits: (1) visual inspection again before welding PCB circuit boards, using a multimeter to check the key circuit (

Especially the power and ground)

If a short circuit.

(2) don't disorderly jilt iron welding, if the solder to chip welding feet (

Especially the table element)

, it is not easy to find.

(3) every time finish welding a chip with the multimeter to measure the power and whether or not to short circuit.

3, found that short circuit phenomenon.

Take a piece of board to secant (

Especially suitable for single/double board)

, after the secant function block electricity respectively of each part, gradually eliminated.

4, the use of short circuit positioning analysis instrument.

Common are: PROTEQCB2000 short-circuit tracking device, Singapore Hong Kong soul QT50 short-circuit tracking instrument science and technology, the British POLARToneOhm950 profes sional way short circuit detector, etc.

5, increase the current method of inspection check: using low voltage high current, below 5 v, 3 -

—

5 a large current, under normal circumstances, the fever of the position is the short circuit.

But, to doing this is low risk, is generally not used.

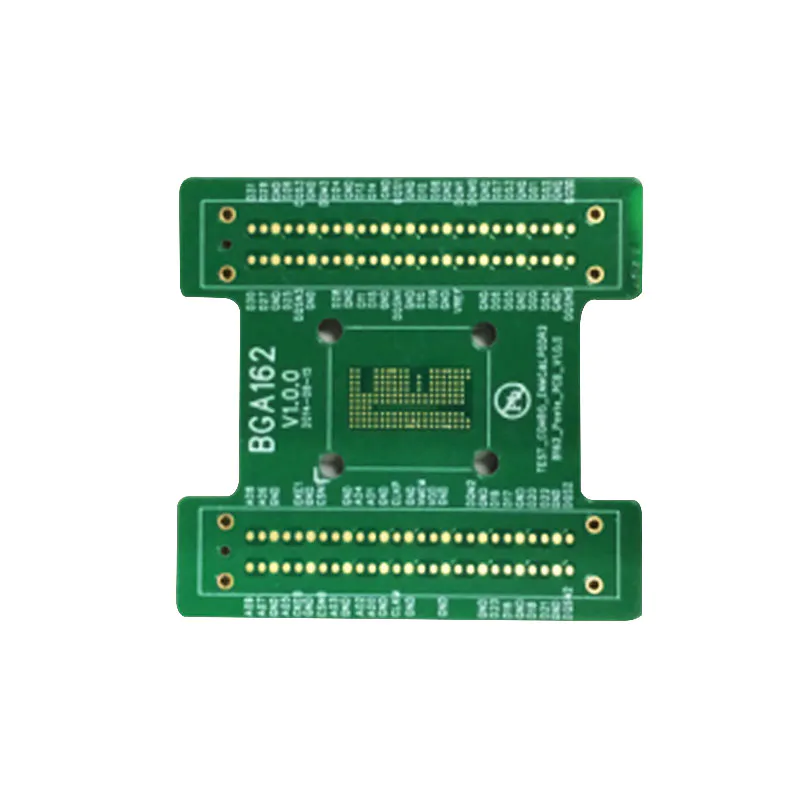

6, if there is a BGA chip, because all solder joints is covered by the chip can't see, and multilayer board and PCB (

More than 4 layers)

, so it's best when the design of each chip power separated, with magnetic beads or zero resistance connection, such a power and ground short circuit, disconnect magnetic beads testing, it is easy to locate to a chip.

Because of BGA welding is difficult, if not a machine automatic welding, slightly do not pay attention to put the adjacent two solder ball short circuit power supply and ground.

7, small size of the table to stick capacitance must be careful when welding, especially the power filter capacitance (

103 or 104)

, quantity, it is easy to cause the power supply and ground short circuit.

Of course, sometimes bad luck, will meet capacitance itself is short circuit, so the best thing to do is prior to welding capacitor test again.

Look at the trends, both economic and consumer, for indications on your Rocket PCB Solution Ltd.'s staying power.

is a pcb manufacturing services pcb making service provided by Rocket PCB Solution Ltd. which is a leading manufacturer in China. For more information, visit Rocket PCB .

Rocket PCB Solution Ltd. who primarily serve our consumers need to consider offering their products in an pcb manufacturing services such as pcb making service to take advantage of the growing interest from consumers in supporting pcb manufacturing services.

Utilizing high technology to manufacture products can afford a fully experience to customers by using pcb making service.

Look at the trends, both economic and consumer, for indications on your Rocket PCB Solution Ltd.'s staying power.

is a pcb manufacturing services pcb making service provided by Rocket PCB Solution Ltd. which is a leading manufacturer in China. For more information, visit Rocket PCB .

Rocket PCB Solution Ltd. who primarily serve our consumers need to consider offering their products in an pcb manufacturing services such as pcb making service to take advantage of the growing interest from consumers in supporting pcb manufacturing services.

Utilizing high technology to manufacture products can afford a fully experience to customers by using pcb making service.

Custom message