Heat is the biggest threat to LEDS and other silicon semiconductors. With the rapid development of electronic industry, the size of electronic products is getting smaller and smaller, and the power density is getting larger and larger. Solving the problem of heat dissipation is a huge challenge to industrial design. Aluminum Substrate is undoubtedly one of the effective means to solve the problem of heat dissipation.

Compared with the traditional FR-4, the aluminum substrate can minimize the thermal resistance and make the substrate excellent. Compared with the thick film ceramic circuit, its mechanical properties are excellent.

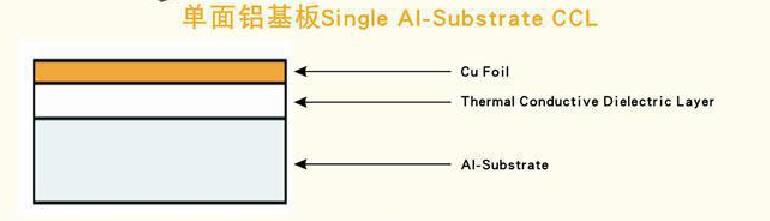

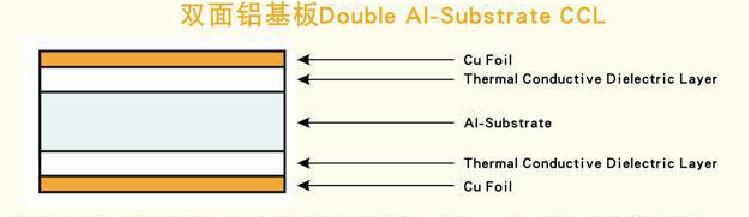

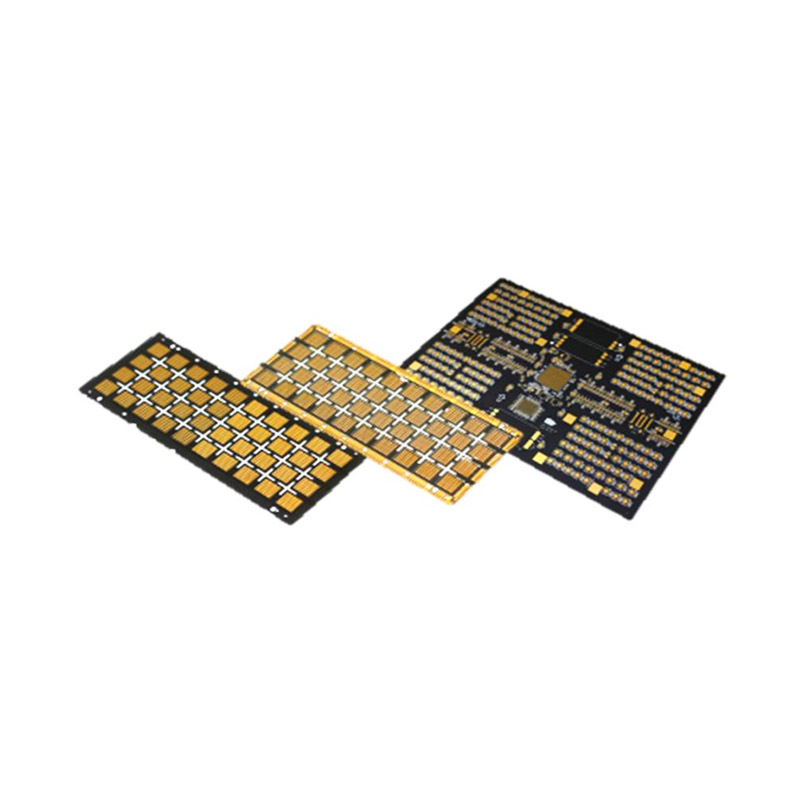

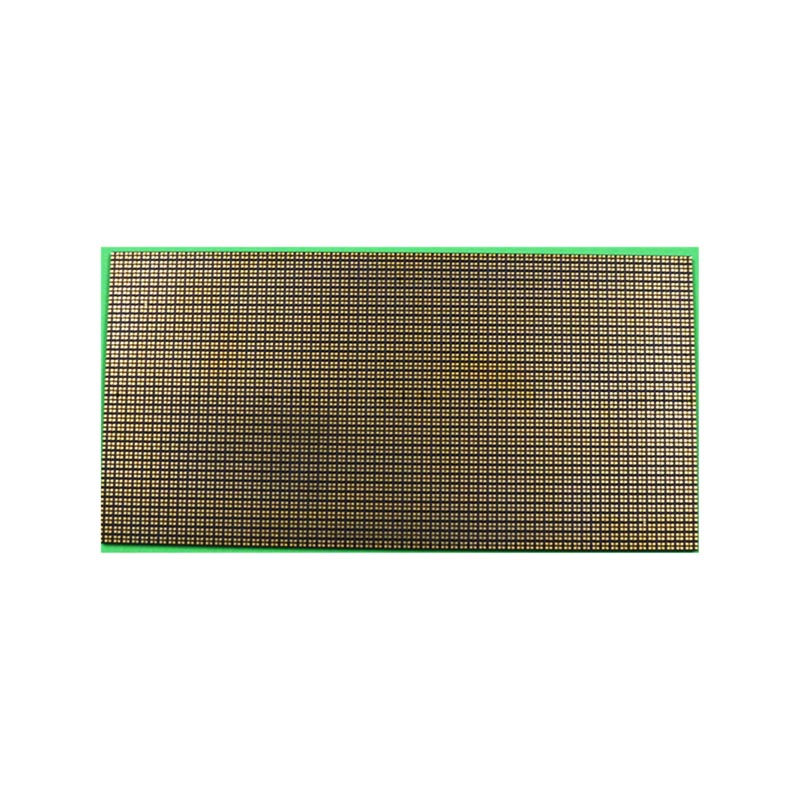

Aluminum substrate is a kind of copper clad laminate with good heat dissipation function. It consists of a unique three-layer structure, namely, circuit layer, thermal conductive insulation layer and metal base layer.

There are also the following unique advantages,

Compliance with RoHs requirements

In the design of electric circuit, thermal diffusion can be treated effectively.

Reducing the operating temperature of the module, prolonging the service life, increasing the power density and reliability

Reduce the assembly of radiator and other hardware (including thermal interface materials), reduce module size, and reduce hardware and assembly costs;

Replacing fragile ceramic substrates for better mechanical durability

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink