Advancements in Ceramic PCB Technology: Enhancing Performance and Reliability

I. Introduction

Ceramic PCBs play a crucial role in electronic devices, offering numerous advantages over traditional PCB materials. Ceramic PCBs are increasingly important in various applications with their unique properties and exceptional performance characteristics. These advanced PCBs provide improved thermal management, enhanced electrical performance, and increased reliability, making them highly sought after in the electronics industry.

This article aims to provide valuable information to potential buyers regarding the latest advancements in Ceramic PCB technology. By exploring the advances in Ceramic PCBs, we aim to assist buyers in making informed decisions and understanding how these advancements can enhance the performance and reliability of their electronic devices. Whether you are a professional engineer or an electronics enthusiast, this article will serve as a comprehensive guide to the advancements in Ceramic PCB technology and their benefits in various applications.

II. Overview of Ceramic PCBs

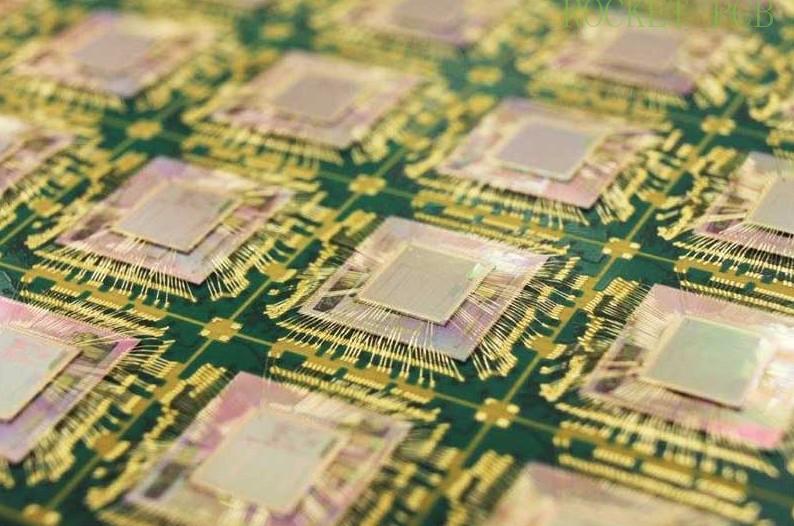

Ceramic PCBs, or Ceramic Printed Circuit Boards, are substrates made from ceramic materials such as aluminium oxide (Al2O3) or aluminium nitride (AlN). These materials possess unique properties that make them highly desirable for electronic applications.

Ceramic PCBs exhibit exceptional characteristics, including high thermal conductivity, excellent electrical insulation properties, and remarkable mechanical strength. These properties make them ideal for applications that require efficient heat dissipation, reliable electrical performance, and durability in harsh environments.

A. Advantages over traditional PCB materials:

Compared to traditional PCB materials like FR4, Ceramic PCBs offer several distinct advantages. Firstly, their high thermal conductivity allows for efficient heat dissipation, crucial for devices operating at high power or in environments with limited heat dissipation capabilities. The superior thermal management of Ceramic PCBs helps prevent overheating, which can degrade component performance and reliability.

Secondly, Ceramic PCBs possess excellent electrical insulation properties, allowing them to withstand high voltages without breakdown. This characteristic is essential for applications that require reliable electrical isolation and safety.

Moreover, Ceramic PCBs exhibit higher mechanical strength than traditional materials, making them more resistant to mechanical stress, vibration, and thermal expansion. This increased durability contributes to the overall reliability and longevity of electronic devices.

B. Common applications of Ceramic PCBs:

The exceptional properties of Ceramic PCBs make them suitable for various applications across industries. Some typical applications include:

1. Power electronics: Ceramic PCBs are widely used in power modules, inverters, and motor drives, where efficient heat dissipation and high electrical insulation are critical.

2. LED lighting: Ceramic PCBs are employed in LED modules and light engines, benefiting from their thermal management capabilities to ensure optimal performance and longevity.

3. Automotive electronics: Ceramic PCBs are utilized in automotive engine control units, transmission control modules, and powertrain systems, where they provide reliability under extreme temperature conditions and high-vibration environments.

4. Aerospace and defence: Ceramic PCBs are preferred in avionics, radar systems, and satellite communication equipment due to their ability to withstand temperature fluctuations, high humidity, and mechanical stress.

The versatility of Ceramic PCBs allows for their application in various other industries, including telecommunications, medical devices, industrial automation, and renewable energy systems.

III. Performance Enhancements in Ceramic PCB Technology

A. Improved thermal management

Advancements in Ceramic PCB technology have revolutionized thermal management in electronic devices. Ceramic materials have excellent heat dissipation properties, making them ideal for enhancing thermal management in PCB designs. The high thermal conductivity of ceramics allows for the efficient transfer of heat generated by electronic components, preventing overheating and ensuring optimal performance.

Furthermore, thermal conductivity advancements have further improved Ceramic PCBs' heat dissipation capabilities. Manufacturers have developed innovative ceramic materials with enhanced thermal conductivity properties, allowing for even better heat dissipation. These advancements enable electronic devices to operate at higher power levels while maintaining lower temperatures, improving overall performance and reliability.

B. Enhanced electrical performance

Ceramic PCBs exhibit superior electrical performance compared to traditional PCB materials, leading to improved functionality and reliability in electronic devices.

1. Higher dielectric strength and reduced signal loss: Ceramic materials offer high dielectric strength, allowing Ceramic PCBs to withstand higher voltages without electrical breakdown. This characteristic is vital in applications that require reliable electrical insulation, such as power electronics and high-voltage systems. Additionally, Ceramic PCBs have a lower signal loss, enabling better signal transmission and minimizing distortion or degradation of electrical signals.

2. Low-loss material options and improved signal integrity: Advancements in Ceramic PCB technology have introduced low-loss ceramic materials, further enhancing signal integrity and reducing signal loss. Low-loss materials have lower electrical impedance, allowing for efficient signal transmission, especially in high-frequency applications. The improved signal integrity ensures accurate and reliable data transmission, benefiting industries such as telecommunications, wireless communication, and high-speed data transfer.

C. Increased reliability and durability

Ceramic PCB technology advancements have significantly improved electronic devices' reliability and durability, even in challenging operating conditions.

1. Resistance to temperature fluctuations and moisture: Ceramic PCBs demonstrate exceptional resistance to temperature variations, making them highly reliable in environments with extreme temperature fluctuations. This property is critical for applications subjected to rapid temperature changes or harsh thermal conditions. Additionally, Ceramic PCBs exhibit excellent resistance to moisture, preventing damage caused by humidity or exposure to water. This moisture resistance ensures the longevity and reliability of electronic devices, even in humid or wet environments.

2. Improved mechanical strength and vibration resistance: Ceramic PCBs offer superior mechanical strength and resistance to vibration and mechanical stress. These properties make them highly suitable for applications where devices may experience mechanical shocks, vibrations, or physical impacts. Industries such as automotive, aerospace, and industrial automation benefit from the robustness of Ceramic PCBs, as they ensure the integrity of the PCB assembly and the overall reliability of the electronic system.

D. Miniaturization and high-density designs

Advancements in Ceramic PCB technology have facilitated the miniaturization of electronic devices and the development of high-density designs.

1. Explore advancements in manufacturing techniques for smaller form factors: Ceramic PCB manufacturing techniques have evolved to support the fabrication of smaller, more compact electronic devices. Advanced processes such as thin-film deposition, laser drilling, and precision etching enable the creation of intricate and precise circuit patterns on Ceramic PCBs. These advancements allow for the realization of smaller form factors without compromising performance or functionality.

2. Benefits of high-density interconnects: Ceramic PCBs enable high-density interconnects, which involve closely spaced and complex routing of traces and vias. The excellent dimensional stability of ceramics and advanced manufacturing techniques allow for rigid and compact circuitry creation. High-density interconnects enhance signal transmission, reduce signal crosstalk, and enable the integration of more components within a limited space. This results in more efficient and powerful electronic devices with reduced footprints.

IV. Factors to Consider When Purchasing Ceramic PCBs

A. Compatibility with specific applications

When purchasing Ceramic PCBs, it is essential to consider their Compatibility with the specific application requirements. Evaluate factors such as thermal conductivity, electrical insulation properties, and mechanical strength to ensure they align with your application's demands. Different ceramic materials may have varying characteristics, so choose the one that best suits your needs.

B. Design requirements and customization options

Consider the design requirements of your electronic device and determine if the Ceramic PCB can accommodate them. Assess factors such as board size, number of layers, and component placement. Additionally, inquire about customization options manufacturers offer to tailor the Ceramic PCB to your specific design needs.

C. Manufacturing processes and quality control measures

Examine the manufacturing processes employed by the Ceramic PCB manufacturer. Look for companies that utilize advanced manufacturing techniques, such as precision drilling and surface treatment. Additionally, inquire about the quality control measures in place to ensure the reliability and consistency of the Ceramic PCBs. This includes checking for adherence to industry standards and certifications.

D. Cost considerations and return on investment

Evaluate the cost of Ceramic PCBs about their performance and reliability benefits. While Ceramic PCBs may have a higher upfront cost than traditional PCB materials, consider the long-term return on investment—factor in the potential for improved device performance, increased lifespan, and reduced maintenance or replacement costs. Additionally, consider the cost savings resulting from enhanced thermal management and reliability, which can minimize the risk of device failures and associated expenses.

By considering these factors when purchasing Ceramic PCBs, you can make informed decisions and ensure that the chosen PCBs meet the specific requirements of your application while providing the desired performance and reliability.

V. Case Studies and Success Stories

A. Highlight real-world examples of Ceramic PCB applications

Real-world examples of Ceramic PCB applications showcase the diverse range of industries that benefit from the advancements in Ceramic PCB technology. Here are a few notable case studies:

l Power Electronics: In the renewable energy sector, Ceramic PCBs are utilized in solar inverters to ensure efficient power conversion and thermal management. Their high thermal conductivity and durability enable reliable operation in demanding outdoor environments.

l LED Lighting: Ceramic PCBs are extensively used in high-power LED lighting applications. By effectively dissipating heat generated by LEDs, Ceramic PCBs improve the lifespan and performance of lighting fixtures, resulting in energy-efficient and long-lasting illumination.

l Automotive Electronics: Ceramic PCBs are employed in automotive engine control units (ECUs) and transmission control modules (TCMs). These applications require reliable performance under extreme temperature conditions, high vibration, and moisture. Ceramic PCBs provide the necessary durability and reliability for critical automotive systems.

B. Positive outcomes and benefits experienced by users

The implementation of Ceramic PCBs in various industries has yielded significant benefits and positive outcomes for users:

l Enhanced Performance: Users report improved device performance, especially in applications with high power density or high-speed data transmission. Ceramic PCBs' superior thermal management capabilities ensure reliable operation and prevent performance degradation due to overheating.

l Increased Reliability: Ceramic PCBs' resistance to temperature fluctuations, moisture, and mechanical stress significantly enhances the reliability of electronic devices. Users experience reduced failure rates, increased product lifespan, and improved system reliability.

l Miniaturization and Design Flexibility: The advancements in Ceramic PCB technology have facilitated miniaturization and enabled high-density designs. Users benefit from smaller form factors without sacrificing performance, allowing the development of sleeker, more compact devices.

l Cost Savings: Although Ceramic PCBs may have a higher upfront cost, users report long-term cost savings. Improved thermal management and reliability reduce maintenance and replacement costs, while enhanced electrical performance ensures efficient operation and minimizes downtime.

These case studies and success stories highlight the tangible benefits experienced by users in different industries, demonstrating the effectiveness of Ceramic PCBs in meeting their specific application requirements.

VI. Conclusion

The advancements in Ceramic PCB technology have revolutionized the electronics industry, offering improved performance and reliability for electronic devices. Ceramic PCBs have emerged as a leading solution, and potential buyers should consider their benefits for their specific electronic device requirements.

Rocket PCB, with its team of over 100 technical staff, has established itself as a leader in innovative electronics manufacturing services. They have successfully translated dreams into reality by offering a wide range of high-quality PCB solutions. Their product portfolio includes rigid, rigid-flex, HDI, any layer, Flex, large-size, embedded, RF, LED, backplane, metal substrate, a ceramic substrate, IC structure, high-frequency, and heavy copper PCBs, which undergo strict surface treatment processes.

Rocket PCB's products cater to various industries, including communication, medical, military, security, industrial, and automotive. They have developed high-speed server boards, large data memory circuit boards, high-frequency hybrid boards, multi-stage HDI boards, IOT modules, security circuit boards, and more. These products are widely used globally, with distribution in North America, Europe, Asia Pacific, and other international regions.

By choosing Rocket PCB as a trusted partner, potential buyers can benefit from their expertise, advanced manufacturing capabilities, and commitment to delivering high-quality PCB prototypes and batch production. Rocket PCB's comprehensive range of Ceramic PCBs and strict quality control measures ensure that electronic devices achieve optimal performance, reliability, and longevity.

In the rapidly evolving electronics industry, Rocket PCB continues to provide innovative solutions and meet ever-increasing market demands. As electronic devices become more sophisticated and complex, Ceramic PCBs offer a reliable foundation for achieving enhanced performance, improved thermal management, and increased reliability.

Potential buyers are encouraged to explore the offerings of Rocket PCB and leverage the advancements in Ceramic PCB technology to propel their electronic devices to new heights of performance, reliability, and success.