A Hard Disk Drive Under The Microscope

by:Rocket PCB

2019-08-28

Users often try to handle the situation themselves.The desire of this qualified user to recover the information himself is understandable.!At home.They don\'t admit it.But where did the fingerprints on the hard disk mirror come from?Do you think the robot did not wash his hands before assembling the equipment on the assembly line?Are there physically damaged elements in the hard disk box?In this case, nothing can be done.

A head crashed?Our experts can help you.

They will open the box, install a new head and read the lost data.However, in this case, it is possible to recover data only from the hard disk.use is not.Everyone knows.The operating system is stored there.It also loads from the hard disk into the memory of the computer.

A fully sealed hard drive metal box looks reliable and durable.Such an impression may be the reason for dealing with roughness.Therefore, data loss and equipment failure are inevitable.

To understand the possible causes of a hard disk failure, let\'s familiarize ourselves with the device structure and how it works.What Is Inside?The operation is based on the principle that the magnetic signal writes/reads the rotating disk.Covered by a magnetic sensitive working layer.

Each side of the disc covered by the working layer is called the working face.When digital data is written, it is converted to analog electrical signals.They created sections with different magnetized values with the help of the writing head.

These sections are distributed along the perimeter of the entire worksheet of the rotating disk.They are called tracks.The distance between the section size and the adjacent track defines the surface density of the data record.When the disk reading session moves under the head.

They sense electrical signals inside.

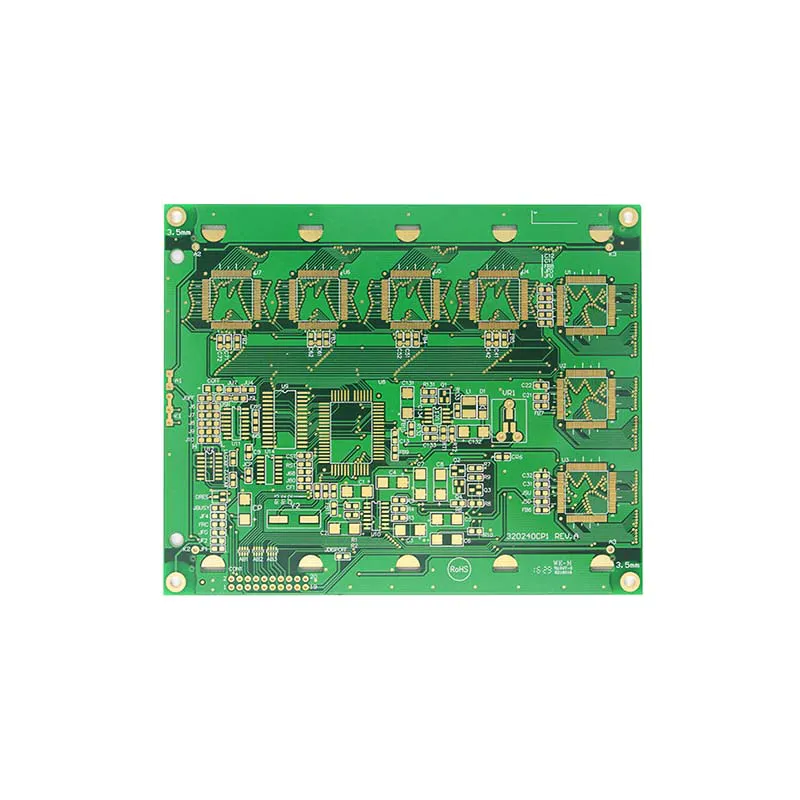

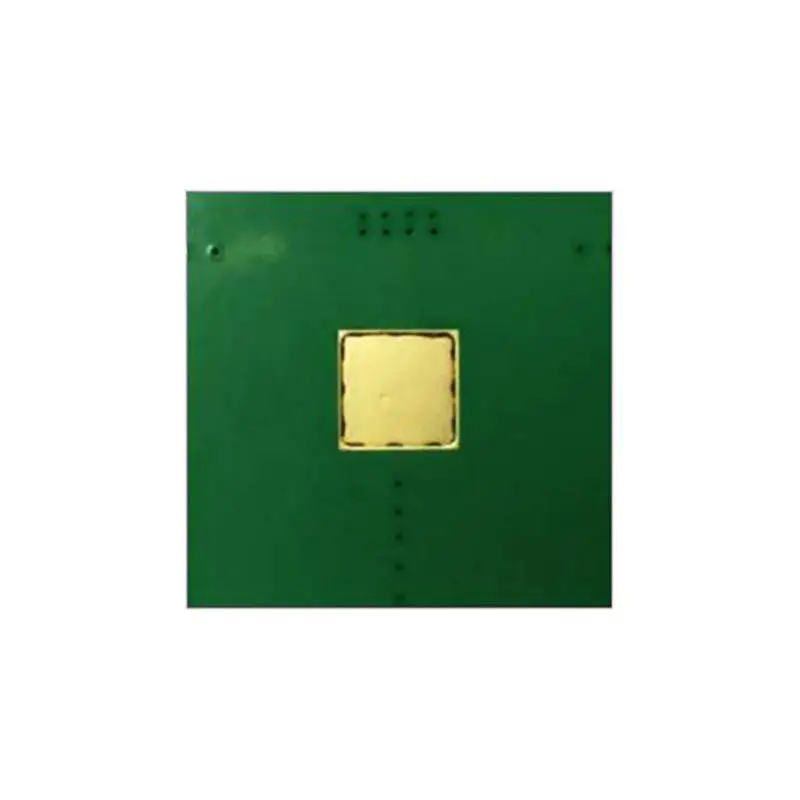

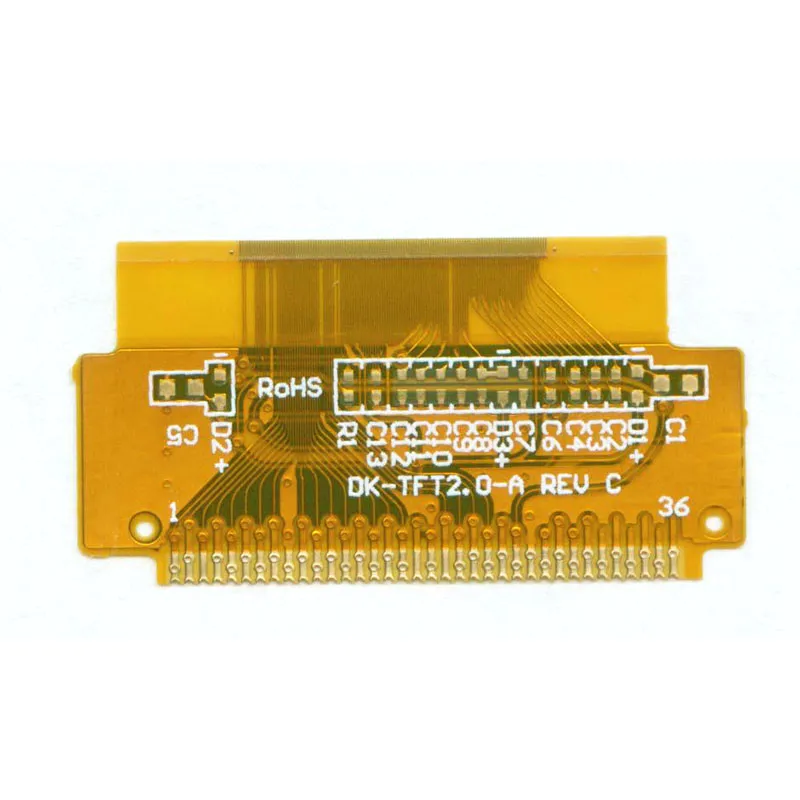

These signals are then converted into digital data.Typical modern hard drive consists of Disc Assembly, speed spindle motor, head block for write/read, pre-Switch devices and controllers.The latter is a printed circuit board with control electronics.

In idle mode, the working carrier presses the head on the surface of the disc.This happens in a special non-The work area known as the landing area.The first hard disk model requires a special head landing operation.

It was initiated by software.

In modern hard drives, the operation of placing the head in the landing area is performed automatically.This happens when the motor speed is lower than the rated speed.Or when the power supply failsThe head can only be placed in the work area at the nominal rotary disc speed.

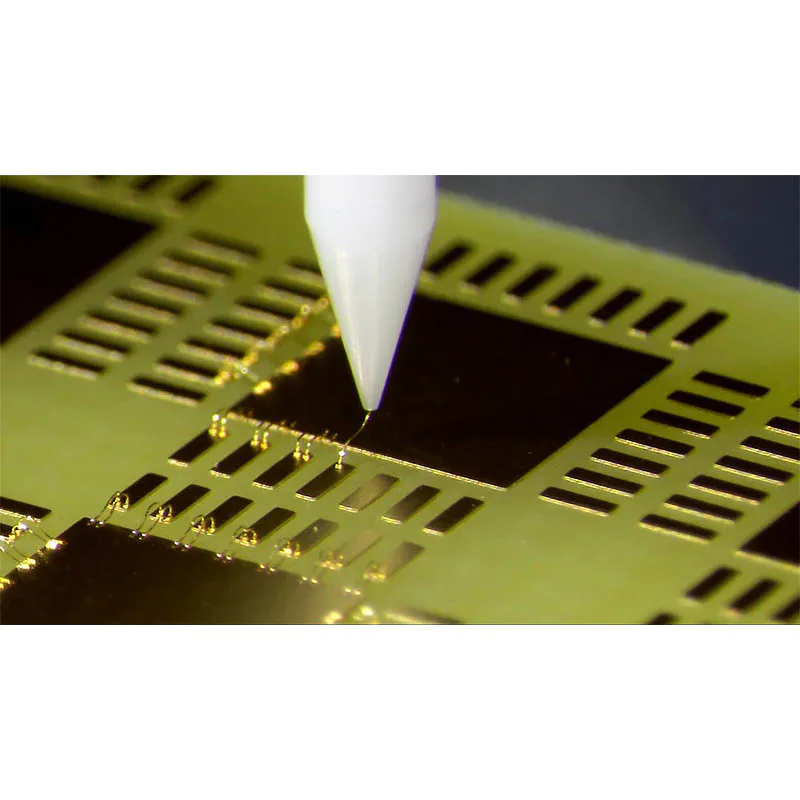

The gap between the head and the surface of the disc is several hundred micrometers.The maximum face density is largely determined by the structure and head features..They are miniature inductive coils.The coils were injured on the magnetic core.

Later, the engineers started using thin-Thin Film head.Today high-A sensitive resistor reader was used.Their working principle is based on the influence of some semiconductors in the magnetic field.

These heads are structurally thinFilm recording headThe head is assembled in one piece.In today\'s hard drive, a head block positioning system with a rotating removable coil is used.The coil is placed in the gap of a powerful permanent magnet.

The coil is the executive mechanism of the positioning system.The core of this system is the preliminary recording of special digital sequences.They are called servo marks.The servo mark is recorded to the appropriate sector of each track.

During the operation, the controller is guided by these markers.It generates a control signal.They went to a movable coil.Then the head rotates so that it is fixed directly on the track.The head remains in these positions on the track until the command to change the head position comes.

To increase the recording density, the gap between the hard disk surface and the head should be reduced to a minimum.In today\'s hard drives, this problem is solved by using an aerodynamic lift.It is produced by air flow.The rotating disk surface carries air flow.

The head face is in the form of a wing.

This is done in order to generate an uplifting force.The head is fixed by an elastic working carrier.Therefore, it will not \"fly away\" from the surface of the disk.

The size of the lift is defined by the air density.Air density is-Turn according to atmospheric pressure.Therefore, the average hard disk has the maximum lifting height.

above-sea-Level limit.

They\'re about 2000.

3000 m.

In today\'s hard drive, the disc set may have a speed of 15,000 r/min.But high speed can cause some problems.They are related to balance, gyro effect and head aerodynamics.During the operation, the head should never have physical contact with the working surface.

Accidental contact almost always results in complete or partial damage to the corresponding track.This also often leads to head collisions.There is a disc assembly, an engine and a head block in a sealed box --an HDA.It comes with a removable cover.The internal volume of HDA is not isolated from the external environment.

It is always possible to let air flow into HDA and vice versa.It is necessary to equal the pressure inside the HDA to the external pressure to prevent deformation of the shell.This problem by using so-Called air pressure filterIt is placed inside the HDA.

The filter is able to hold certain particles.Their dimensions must exceed the working gap between the head and the working surface.In addition, they damage the working face and head if in the work gap.

Therefore, the tightness of the shell is only that these particles cannot enter the interior.Also, there is always a recycling filter in HDA.It is designed to capture particles that can pop up inside the HDA.

This happens because in the landing area, the surface of the disc falls off when the head \"takes off\" and \"lands.Some particles can also enter the shell through a pneumatic filter.Taking into account the direction of the airflow, select the location of the recovery filter in order to provide the maximum purification efficiency of the airflow inside the HAD.

There are many bottlenecks in such a complex hard disk structure.They lead to different failures.In general, they are related to the natural wear of mechanical blocks and the aging process of electronic components.Typically, the guaranteed average time between faults (MTBF) is 0.

5-1 million hoursThis means that the hard drive is 57-114 years.But this feature is not so much practice as theory.Over time, the magnetic intensity of the working layer gradually weakens.

The recording quality of user files remains almost the same.Files are usually rewritten.But once and for all, manufacturers have recorded servo marks, control department marks, and data in the engineering field.Therefore, data access issues may arise.They are caused by overhead magnetic damping.

.So is the defect matrix.

It can be recovered without losing user data.However, even with the efforts of the manufacturer, it is not possible to restore the servo mark without breaking the data.The working face assigned to indirect information is not less than 16% of the total working face.

It provides the normal operation of the hard disk.First of all, it is the engineering domain (configuration sector, defect matrix, executable hard disk code ).The remaining disc space is divided into areas.

Most hard drives have 8-20 zones.

Each area contains a different number of sectors.Not all departments are used as work departments.Some industries are reserve industries.Initial disc formatting at the manufacturer\'s factory includes disc surface inspection.

The information of the discovery defect point is recorded in the defect matrix.It is located in the engineering area.During hard disk operations, the matrix is used to reassign bad access sectors to good access sectors.The latter plate is located on the reserve track.

Overhead information is important.

Therefore, the engineering field of different hard disk models may contain 2-6 copies.Servo marks include spare marks.They are recorded by more powerful magnetic fields.The disk surface is gradually destroyed during operation.

New bad industries are beginning to emerge.This leadsCalled magnetic media degradation.Frequent write and read errors indicate such problems.

Spindle motor bearings may be worn or damaged.This caused the disc to swing a little.The distance between the head and the working face alternately increases and decreases.This is the reason for the increase in the number of \"minor\" errors and the high risk of head falling on the surface of the hard disk.

Did your hard drive start making strange noises?Or can you hear the click of the head positioning on the stopper?Ready for avalancheLike a hard drive failure quickly.In this case, information can usually be saved.However, hard disk repair work and its further use are not possible.

The instability of the supply voltage may cause the failure of the hard disk controller electronic device.The result may also be magnetic blow.It affects the working surface of the hard disk.Hard drive controller burned-This often happens.

They have serious consequences.

Electronic car-The landing mechanism is not working.Therefore, the head lands on the surface of the disc in the work area (not in the landing area.This will not only cause damage to the sheet surface, but also damage to the head.

Voltage oscillation is another cause of data loss and hard disk failure.Users can prevent these failures.Users can purchase uninterrupted power supply (UPS) with stable voltage ).The common cause of hard disk failure is a violation of the temperature system.

The speed of the disk package reaches 15,000 r/min.In order to improve the dynamic properties, powerful spindle motors and positioning drives are used.They produce a lot of heat.In addition to this, the installation of the bearing will also generate heat.

Hard drives are usually located near other devices in the computer\'s enclosure.Not cold enough.This led to overheating.This could have the most serious consequences.These include the dead spindle motor (coupled with the simultaneous failure of the controller\'s power supply components), damage to the hard disk working layer, and the head glued to the surface of the landing area.

Over-The main factors that cause hard disk failure and data loss are associated with incorrect user actions.Impact and vibration, for example, interfere with balance and disc alignment.This does not necessarily lead to performance loss.

Poor balance can lead to vibration, rapid wear of mounting bearings, overheating of HDA, and finally premature failure of the system.In a disabled state, radial impact is particularly dangerous for hard drives.Typically, these shocks result in a complete loss of hard disk performance and no further use.

In some cases, data recovery can be performed from this medium.But its further operation is impossible.The medium in working condition is vulnerable to radial and axial mechanical impact.The latter may have happened due to such a trivial reason as the unexpected push of the computer housing and other equipment.

In the case of a height of only 0, the head on the surface of the disk.1-0.12 microns.Even a weak stroke is enough to narrow the distance to zero.The track moves under the head at a speed of 90-125 km/h.

Can you imagine the impact of this collision?1mm of the track is equal to 2 bytes.Did you see the loss?Let\'s assume that the damage is trivial.Knocked-Magnetic particles will fly in the outer shell for a long time.

This creates the risk of another failure.

Many particles are still glued to the surface of the disk.This led to a further process of damaging the working face.In addition, when in direct contact with the surface of the disk, the head will overheat in an instant.

Head breaks due to head collision and radial mechanical impact.The equally fatal consequence could be decompression.The sealing of some hard disk models (western numbers, Seagate, Quantum) is provided by adhesive tape.

It stuck down along the perimeter of the hard disk enclosure.This hard drive needs to be very careful when storing, shipping, and installing it in the computer housing.Installing such a hard drive in some computer cases is full of accidental decompression.

Some hard disk models have operating openings.Special stickers are covered.If the user handles the media roughly, he may damage them.Even dust can lead to fatal consequences if HDA is decompressed.

They include progressive destruction of the working layer and head collision.The disc with a decompressed shell does not work properly.A power cord connection error almost always causes a complete failure of the hard disk electronics.

The pre-The switch device in the hard disk enclosure may also be damaged.The user often does not connect the interface cable correctly.The consequences of this operation are difficult to predict.

Sometimes it does not have fatal consequences for media and computer boards.Sometimes there is a failure of the hard disk controller or motherboard interface.In most modern hard drives, such as SMART-Monitoring, Analysis and Reporting technologies are implemented.

The essence of it is that the hard disk can run automatically.Diagnostic examination.The hard disk drive can remind the user of the pre-Emergency in advance.Most smart hard drives to 2-30 attributes of reliability.

These include the number of facts for head positioning, the number of positioning errors, and so on.We recommend that you take some simple and effective measures on a regular basis to prevent data loss.They are well known.But users tend to ignore them.These measures include regular backups.In addition to this, regular use of diagnostic software and defragmenting programs such as Norton Utilities is also helpful.

Regular diagnostics will help you notice the gradual degradation of your hard drive in the right amount of time.Symptoms include declining performance and sluggish industry.In this case, you \'d better copy all the necessary information to another medium.

Data retrieval will diagnose your device.

Our company has all the necessary equipment to tell you if you can use the hard disk further..We will save you time and money

A head crashed?Our experts can help you.

They will open the box, install a new head and read the lost data.However, in this case, it is possible to recover data only from the hard disk.use is not.Everyone knows.The operating system is stored there.It also loads from the hard disk into the memory of the computer.

A fully sealed hard drive metal box looks reliable and durable.Such an impression may be the reason for dealing with roughness.Therefore, data loss and equipment failure are inevitable.

To understand the possible causes of a hard disk failure, let\'s familiarize ourselves with the device structure and how it works.What Is Inside?The operation is based on the principle that the magnetic signal writes/reads the rotating disk.Covered by a magnetic sensitive working layer.

Each side of the disc covered by the working layer is called the working face.When digital data is written, it is converted to analog electrical signals.They created sections with different magnetized values with the help of the writing head.

These sections are distributed along the perimeter of the entire worksheet of the rotating disk.They are called tracks.The distance between the section size and the adjacent track defines the surface density of the data record.When the disk reading session moves under the head.

They sense electrical signals inside.

These signals are then converted into digital data.Typical modern hard drive consists of Disc Assembly, speed spindle motor, head block for write/read, pre-Switch devices and controllers.The latter is a printed circuit board with control electronics.

In idle mode, the working carrier presses the head on the surface of the disc.This happens in a special non-The work area known as the landing area.The first hard disk model requires a special head landing operation.

It was initiated by software.

In modern hard drives, the operation of placing the head in the landing area is performed automatically.This happens when the motor speed is lower than the rated speed.Or when the power supply failsThe head can only be placed in the work area at the nominal rotary disc speed.

The gap between the head and the surface of the disc is several hundred micrometers.The maximum face density is largely determined by the structure and head features..They are miniature inductive coils.The coils were injured on the magnetic core.

Later, the engineers started using thin-Thin Film head.Today high-A sensitive resistor reader was used.Their working principle is based on the influence of some semiconductors in the magnetic field.

These heads are structurally thinFilm recording headThe head is assembled in one piece.In today\'s hard drive, a head block positioning system with a rotating removable coil is used.The coil is placed in the gap of a powerful permanent magnet.

The coil is the executive mechanism of the positioning system.The core of this system is the preliminary recording of special digital sequences.They are called servo marks.The servo mark is recorded to the appropriate sector of each track.

During the operation, the controller is guided by these markers.It generates a control signal.They went to a movable coil.Then the head rotates so that it is fixed directly on the track.The head remains in these positions on the track until the command to change the head position comes.

To increase the recording density, the gap between the hard disk surface and the head should be reduced to a minimum.In today\'s hard drives, this problem is solved by using an aerodynamic lift.It is produced by air flow.The rotating disk surface carries air flow.

The head face is in the form of a wing.

This is done in order to generate an uplifting force.The head is fixed by an elastic working carrier.Therefore, it will not \"fly away\" from the surface of the disk.

The size of the lift is defined by the air density.Air density is-Turn according to atmospheric pressure.Therefore, the average hard disk has the maximum lifting height.

above-sea-Level limit.

They\'re about 2000.

3000 m.

In today\'s hard drive, the disc set may have a speed of 15,000 r/min.But high speed can cause some problems.They are related to balance, gyro effect and head aerodynamics.During the operation, the head should never have physical contact with the working surface.

Accidental contact almost always results in complete or partial damage to the corresponding track.This also often leads to head collisions.There is a disc assembly, an engine and a head block in a sealed box --an HDA.It comes with a removable cover.The internal volume of HDA is not isolated from the external environment.

It is always possible to let air flow into HDA and vice versa.It is necessary to equal the pressure inside the HDA to the external pressure to prevent deformation of the shell.This problem by using so-Called air pressure filterIt is placed inside the HDA.

The filter is able to hold certain particles.Their dimensions must exceed the working gap between the head and the working surface.In addition, they damage the working face and head if in the work gap.

Therefore, the tightness of the shell is only that these particles cannot enter the interior.Also, there is always a recycling filter in HDA.It is designed to capture particles that can pop up inside the HDA.

This happens because in the landing area, the surface of the disc falls off when the head \"takes off\" and \"lands.Some particles can also enter the shell through a pneumatic filter.Taking into account the direction of the airflow, select the location of the recovery filter in order to provide the maximum purification efficiency of the airflow inside the HAD.

There are many bottlenecks in such a complex hard disk structure.They lead to different failures.In general, they are related to the natural wear of mechanical blocks and the aging process of electronic components.Typically, the guaranteed average time between faults (MTBF) is 0.

5-1 million hoursThis means that the hard drive is 57-114 years.But this feature is not so much practice as theory.Over time, the magnetic intensity of the working layer gradually weakens.

The recording quality of user files remains almost the same.Files are usually rewritten.But once and for all, manufacturers have recorded servo marks, control department marks, and data in the engineering field.Therefore, data access issues may arise.They are caused by overhead magnetic damping.

.So is the defect matrix.

It can be recovered without losing user data.However, even with the efforts of the manufacturer, it is not possible to restore the servo mark without breaking the data.The working face assigned to indirect information is not less than 16% of the total working face.

It provides the normal operation of the hard disk.First of all, it is the engineering domain (configuration sector, defect matrix, executable hard disk code ).The remaining disc space is divided into areas.

Most hard drives have 8-20 zones.

Each area contains a different number of sectors.Not all departments are used as work departments.Some industries are reserve industries.Initial disc formatting at the manufacturer\'s factory includes disc surface inspection.

The information of the discovery defect point is recorded in the defect matrix.It is located in the engineering area.During hard disk operations, the matrix is used to reassign bad access sectors to good access sectors.The latter plate is located on the reserve track.

Overhead information is important.

Therefore, the engineering field of different hard disk models may contain 2-6 copies.Servo marks include spare marks.They are recorded by more powerful magnetic fields.The disk surface is gradually destroyed during operation.

New bad industries are beginning to emerge.This leadsCalled magnetic media degradation.Frequent write and read errors indicate such problems.

Spindle motor bearings may be worn or damaged.This caused the disc to swing a little.The distance between the head and the working face alternately increases and decreases.This is the reason for the increase in the number of \"minor\" errors and the high risk of head falling on the surface of the hard disk.

Did your hard drive start making strange noises?Or can you hear the click of the head positioning on the stopper?Ready for avalancheLike a hard drive failure quickly.In this case, information can usually be saved.However, hard disk repair work and its further use are not possible.

The instability of the supply voltage may cause the failure of the hard disk controller electronic device.The result may also be magnetic blow.It affects the working surface of the hard disk.Hard drive controller burned-This often happens.

They have serious consequences.

Electronic car-The landing mechanism is not working.Therefore, the head lands on the surface of the disc in the work area (not in the landing area.This will not only cause damage to the sheet surface, but also damage to the head.

Voltage oscillation is another cause of data loss and hard disk failure.Users can prevent these failures.Users can purchase uninterrupted power supply (UPS) with stable voltage ).The common cause of hard disk failure is a violation of the temperature system.

The speed of the disk package reaches 15,000 r/min.In order to improve the dynamic properties, powerful spindle motors and positioning drives are used.They produce a lot of heat.In addition to this, the installation of the bearing will also generate heat.

Hard drives are usually located near other devices in the computer\'s enclosure.Not cold enough.This led to overheating.This could have the most serious consequences.These include the dead spindle motor (coupled with the simultaneous failure of the controller\'s power supply components), damage to the hard disk working layer, and the head glued to the surface of the landing area.

Over-The main factors that cause hard disk failure and data loss are associated with incorrect user actions.Impact and vibration, for example, interfere with balance and disc alignment.This does not necessarily lead to performance loss.

Poor balance can lead to vibration, rapid wear of mounting bearings, overheating of HDA, and finally premature failure of the system.In a disabled state, radial impact is particularly dangerous for hard drives.Typically, these shocks result in a complete loss of hard disk performance and no further use.

In some cases, data recovery can be performed from this medium.But its further operation is impossible.The medium in working condition is vulnerable to radial and axial mechanical impact.The latter may have happened due to such a trivial reason as the unexpected push of the computer housing and other equipment.

In the case of a height of only 0, the head on the surface of the disk.1-0.12 microns.Even a weak stroke is enough to narrow the distance to zero.The track moves under the head at a speed of 90-125 km/h.

Can you imagine the impact of this collision?1mm of the track is equal to 2 bytes.Did you see the loss?Let\'s assume that the damage is trivial.Knocked-Magnetic particles will fly in the outer shell for a long time.

This creates the risk of another failure.

Many particles are still glued to the surface of the disk.This led to a further process of damaging the working face.In addition, when in direct contact with the surface of the disk, the head will overheat in an instant.

Head breaks due to head collision and radial mechanical impact.The equally fatal consequence could be decompression.The sealing of some hard disk models (western numbers, Seagate, Quantum) is provided by adhesive tape.

It stuck down along the perimeter of the hard disk enclosure.This hard drive needs to be very careful when storing, shipping, and installing it in the computer housing.Installing such a hard drive in some computer cases is full of accidental decompression.

Some hard disk models have operating openings.Special stickers are covered.If the user handles the media roughly, he may damage them.Even dust can lead to fatal consequences if HDA is decompressed.

They include progressive destruction of the working layer and head collision.The disc with a decompressed shell does not work properly.A power cord connection error almost always causes a complete failure of the hard disk electronics.

The pre-The switch device in the hard disk enclosure may also be damaged.The user often does not connect the interface cable correctly.The consequences of this operation are difficult to predict.

Sometimes it does not have fatal consequences for media and computer boards.Sometimes there is a failure of the hard disk controller or motherboard interface.In most modern hard drives, such as SMART-Monitoring, Analysis and Reporting technologies are implemented.

The essence of it is that the hard disk can run automatically.Diagnostic examination.The hard disk drive can remind the user of the pre-Emergency in advance.Most smart hard drives to 2-30 attributes of reliability.

These include the number of facts for head positioning, the number of positioning errors, and so on.We recommend that you take some simple and effective measures on a regular basis to prevent data loss.They are well known.But users tend to ignore them.These measures include regular backups.In addition to this, regular use of diagnostic software and defragmenting programs such as Norton Utilities is also helpful.

Regular diagnostics will help you notice the gradual degradation of your hard drive in the right amount of time.Symptoms include declining performance and sluggish industry.In this case, you \'d better copy all the necessary information to another medium.

Data retrieval will diagnose your device.

Our company has all the necessary equipment to tell you if you can use the hard disk further..We will save you time and money

Custom message