2024 Top 10 FPCB Manufacturers in the World

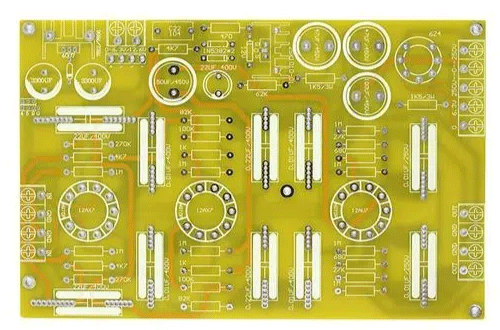

The global PCB industry is developing very rapidly. In recent years, with the advancement of communication technology and the increase in sales of electronic devices, the printed circuit board market has continued to expand. PCB manufacturers and suppliers are facing fierce competition. Here we would like to share the top 10 FPCB manufacturers and suppliers in the world according to. To get more detailed information, you can visit their official website. The following is a list of the top 10 FPCB manufacturers in the world.

List of 11 Flex Printed Circuit Board (PCB) Manufacturers

Ranking | Company Name | English Name | Country | Benefits |

1 | メクテック株式会社 | Nippon Mektron | Japan | Leading in flexible circuit technology, especially for automotive and consumer electronics |

2 | 臻鼎科技控股 | Zhen Ding Technology | China | Major supplier for smartphones and tablets |

3 | 株式会社フジクラ | Fujikura | Japan | Known for high-density flex circuits |

4 | 嘉联益电子(昆山)有限公司 | Career Technologies | Taiwan | Focuses on automotive, medical, and IoT applications |

5 | 인터플렉스 | Interflex | Korea | Supplier for high-end consumer electronics |

6 | 台郡科技股份有限公司 | Flexium Interconnect | Taiwan | Specializes in high-complexity flex circuits |

7 | 住友電気工業株式会社 | Sumitomo Electric | Japan | Offers ultra-fine line flex circuits |

8 | 超毅科技有限公司 | Multek | Taiwan | Specializes in rigid-flex PCBs |

9 | 深圳嘉立创科技发展有限公司 | JLCPCB | China | Known for rapid prototyping and small-batch production |

10 | All Flex | All Flex | USA | Provides high-reliability flex PCBs for medical and military use |

The above companies are renowned for producing high-quality flexible PCBs, each capable of meeting the demands of various industries, including consumer electronics, aerospace, and medical devices. For more detailed information, you can visit their official websites.

Choosing the best flexible printed circuit board can be complex due to differences in services, scale, and geographic focus. Below, we provide an overview of their general market positioning, specialization, and pricing strategies. Comparing the prices and advantages of the top 10 flexible PCB manufacturers may be challenging, but read our full article below to learn everything you need to know about the best flexible PCB providers and how to choose the right one for you.

The Prices And Advantages Of The Top 10 Flex PCB Manufacturers

1. Nippon Mektron (Japan)

· Advantages: Leader in high-volume production, especially in automotive and consumer electronics. Strong R&D focus and a reputation for high quality.

· Pricing: Generally higher, reflecting their advanced technology and high-quality standards.

2. Zhen Ding Technology (China)

· Advantages: Dominates the smartphone and tablet market, offering cost-effective solutions with large production capabilities.

· Pricing: Competitive due to scale, especially for high-volume orders.

3. Fujikura (Japan)

· Advantages: Specializes in high-density flex circuits, making them ideal for compact and complex devices.

· Pricing: Premium pricing, justified by their precision and advanced technology.

4. Career Technologies (Taiwan)

· Advantages: Strong focus on automotive, medical, and IoT applications. Offers a good balance between quality and cost.

· Pricing: Mid-range, offering good value for specialized applications.

5. Interflex (Korea)

· Advantages: Preferred supplier for high-end consumer electronics, with a strong emphasis on reliability and performance.

· Pricing: Moderate to high, depending on the complexity of the project.

6. Flexium Interconnect (Taiwan)

· Advantages: Known for handling highly complex designs, making them a top choice for innovative projects.

· Pricing: On the higher end, particularly for intricate designs and multi-layer circuits.

7. Sumitomo Electric (Japan)

· Advantages: Specializes in ultra-fine line flex circuits, ideal for space-constrained applications.

· Pricing: Higher due to their niche focus on ultra-fine and high-precision circuits.

8. Multek (Taiwan)

· Advantages: Strong in rigid-flex PCBs, with a focus on reliability and durability, making them ideal for industrial and automotive applications.

· Pricing: Competitive for rigid-flex designs, often slightly above average for other types due to their specialization.

9. JLCPCB (China)

· Advantages: Known for rapid prototyping and low-cost production, particularly for small batches and startups.

· Pricing: Very low, especially for prototypes and small runs, with fast turnaround times.

10. All Flex (USA)

· Advantages: Focuses on high-reliability applications in medical and military sectors, with a strong emphasis on quality and customization.

· Pricing: Higher due to the bespoke nature of their services and the rigorous standards they meet.

Price Comparison Summary:

· Lowest Pricing: JLCPCB and Zhen Ding Technology are generally the most cost-effective, especially for high-volume orders or rapid prototyping.

· Mid-Range Pricing: Companies like Career Technologies and Flexium Interconnect offer balanced pricing with specialized capabilities.

· Highest Pricing: Nippon Mektron, Fujikura, and Sumitomo Electric typically command higher prices, justified by their advanced technology and specialized offerings.

Advantages Summary:

· Advanced Technology: Nippon Mektron, Fujikura, and Sumitomo Electric lead in high-tech applications.

· Specialization: Career Technologies and Multek excel in automotive and rigid-flex designs.

· Cost-Effectiveness: JLCPCB and Zhen Ding Technology offer the best value for rapid and high-volume production.

This comparison can help guide your choice based on your specific project needs, whether it's budget, complexity, or the need for cutting-edge technology.

Frequently Asked Questions (FAQ) About Flexible PCB

1.Can a damaged flexible PCB be repaired?

Flexible PCBs generally have flexible properties and complex structures, making them difficult to repair. In some cases, minor damage can be repaired using conductive epoxy or solder bridges, but severe damage may require the replacement of the entire flexible PCB.

2.How can I test the reliability of my flexible PCB?

Reliability testing for flexible PCBs typically involves mechanical stress tests, thermal cycling, and electrical testing to ensure performance under real-world conditions. Please consult industry standards and guidelines for specific testing procedures relevant to your application.

3.How to Make Flex PCBs at Home

In fact, FPC design is basically the same as PCB design!

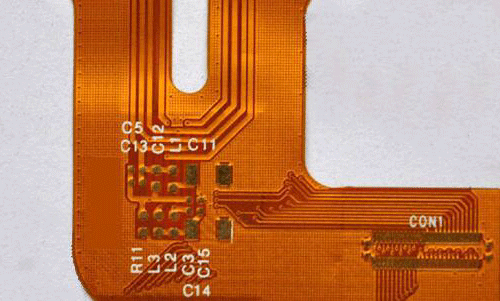

The only difference is that FPC is relatively soft and not convenient for assembly and welding. It is necessary to add some rigid materials to the back of the components or the non-bending areas such as the plug to provide support or facilitate assembly. This rigid material is called reinforcement, and common materials include FR4, steel sheet and PI reinforcement.

Substrate selection: Choose a flexible substrate suitable for the application. Common substrates include polyimide (PI) and polyamide (PET).

Design: Design the circuit diagram and layout of the FPC flexible circuit board according to the circuit requirements and application requirements. Make sure to take into account the bending and folding of the circuit.

Graphic printing: Print the conductive circuit pattern on the flexible substrate using screen printing or other applicable printing processes. Conductive ink or metal foil is usually used to make conductive circuits.

Make a conductive layer: Increase the thickness of the conductive layer on the conductive circuit pattern by electroplating or other methods to improve the conductivity and reliability.

Surface treatment: Perform surface treatment on the conductive layer as needed, such as gold plating, silver plating, etc., to improve contact performance and corrosion resistance.

Cutting: Use methods such as laser cutting or mechanical cutting to cut the FPC board into the required size.

It should be noted that the production process of FPC flexible circuit boards may vary depending on the manufacturer and application requirements. Therefore, when making FPC flexible circuit boards, it is best to refer to the detailed guidelines and process flow provided by the manufacturer.