Why the PCB proofing open? Is there a way to improve?

by:Rocket PCB

2020-04-04

Why the PCB proofing open?

Is there a way to improve?

PCB board factory system: (

火箭PCB解决方案有限公司)

For you to solve!

PCB proofing of the base material of open: 1, copper clad in library before there are wounds.

2, copper clad in hole when the drill tip scratching.

3, copper clad scratches in the cutting process.

4, copper clad in scratches during the transfer process.

At level 5, production board machine scratches on the surface of copper foil.

6, after heavy copper plate piled bruise on surface of copper foil was caused by improper operation.

Improvement methods: 1: copper clad scratches in the cutting process, the main reason is that cutting hard, implements the machine surface exist, when cutting copper clad with the implements friction cause formation of dew copper foil scratches the phenomenon of base material, so must be carefully clean the table before cutting, ensure smooth surface without hard objects exist.

2: copper clad in front of the library in IQC sampling must be: to check whether there is scratch board face dew base material, if any should be timely contact with suppliers, according to the actual situation, make appropriate treatment.

3: plank in the scratches during the transfer process: (

1)

Handling personnel one-off mention when handling the board quantity, the weight is too big, too much plate when handling is not raised, but the momentum drag on, cause voids and surface friction and scratch board face.

(

2)

Put down the plate for not up, in order to rearrange good and hard to push board, causing friction between plate and plate and cut the plate.

4: copper clad in a hole when the drill tip cut: the main reason is that the spindle tip frayed, or clip nozzle with sundry not clean, PCB proofing, scratching drill tip when not firm, drilling tsui didn't come up to the top, drill tip length slightly longer than setting, lift height is not enough, when drilling machine moves drill tip pointed cut copper foil to form the phenomenon of base material.

(

1)

Can catch a knife record the number of times or according to the degree of wear of nozzle, nozzle for replacement.

(

2)

According to operation procedures regularly clean the nozzle, ensure clip inside the nozzle without sundry.

5: after the heavy copper: full stack plate after plate electroplating heavy copper scratches due to improper operation, the whole plate electroplating after storage plate, due to the plate fold together, have a certain number, weight, and then down, down voids and add a gravitational acceleration, the impact of the form a powerful impact on the surface, causing surface scratch base material.

6: the production of plate at a level machine: (scratches

1)

Grinding machine of baffle sometimes comes into contact with the plate surface, the edge is generally not flat baffle and favorable implements bump, crossing board surface scratches.

(

2)

Stainless steel shaft, due to the damage into a pointed object, when a plate cut copper surface and base material.

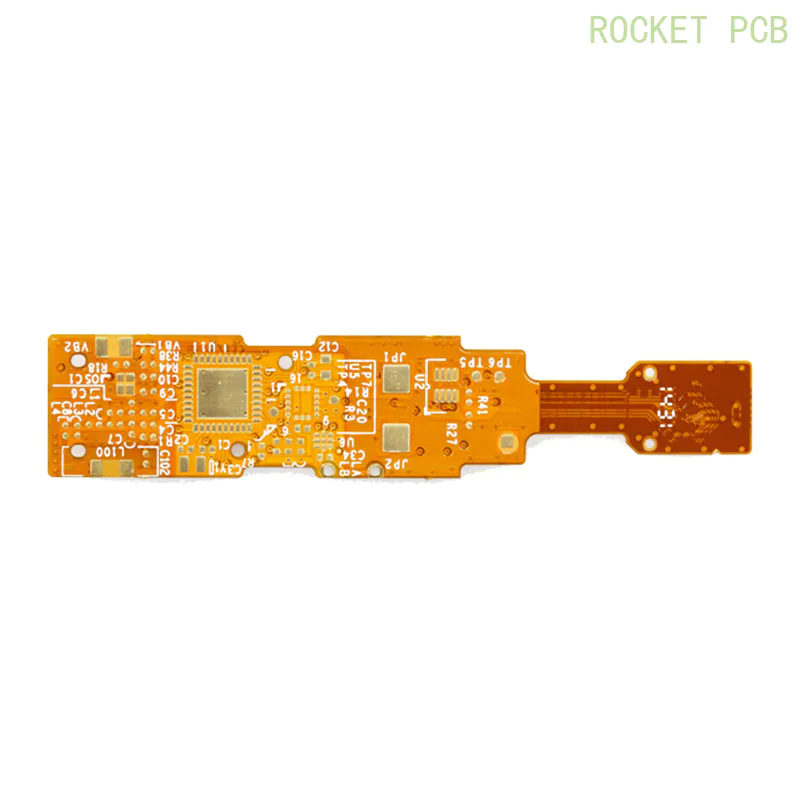

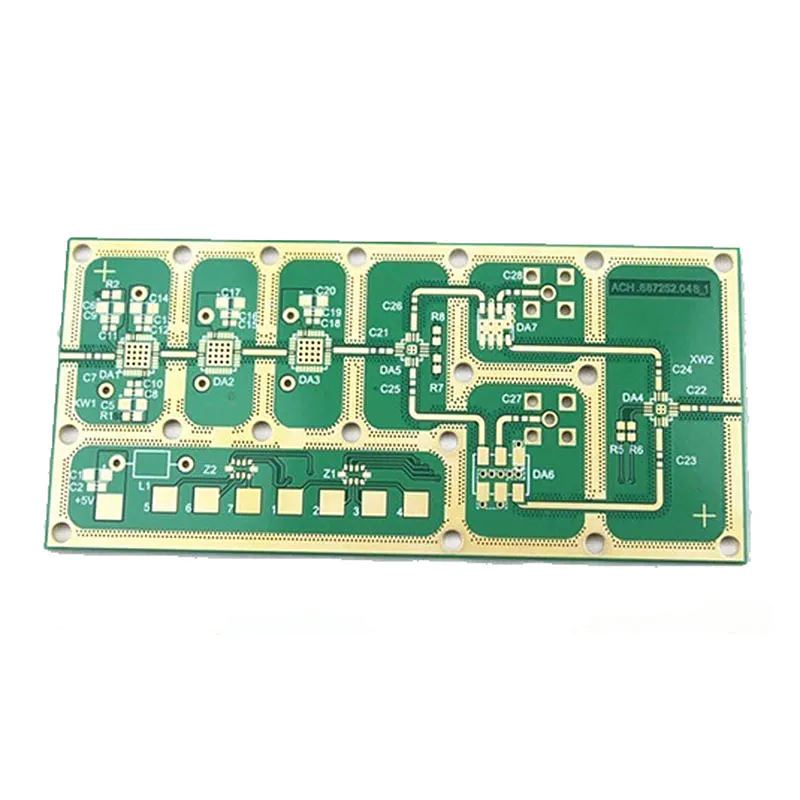

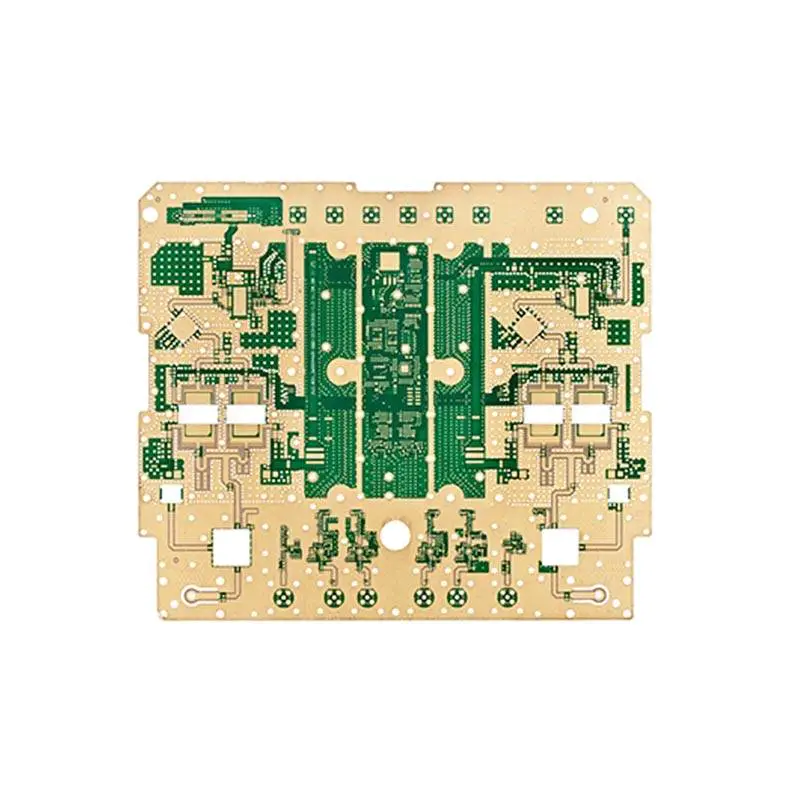

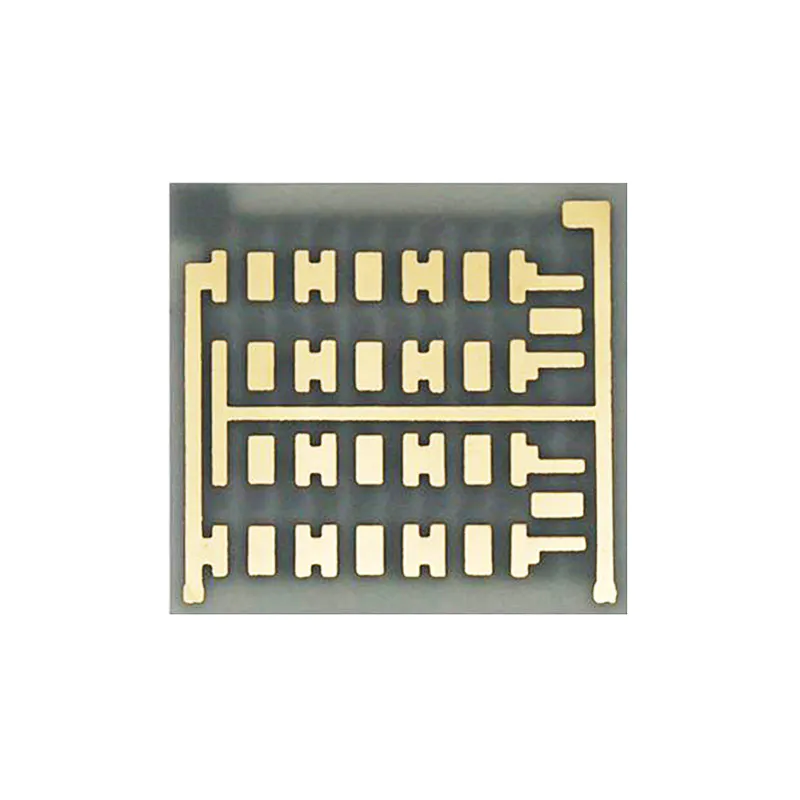

Rocket PCB Solution co Ltd is a professional: PCB manufacture manufacturer, to provide you with: PCB proofing, batch plate, 1 -

34 layer PCB board, high TG board, impedance board, HDI board, Rogers plate, microwave plate, radio frequency (rf) board, LeiDaBan, thick copper foil board, such as PCB manufacturing production of various kinds of technology and material.

Welcome to consult customer service for more details.

Custom message