Company Advantages1. The design of Rocket PCB

pcb assembly is completed by strictly adopting the refrigeration principle. It is completed by our designers who try to make the most of thermal energy.

2. The product can eliminate bacteria, virus, and part of the heavy metals. By exerting a certain pressure on the water to allow only the Ionic mineral elements and hydrone to go through the reverse osmosis membrane.

3. Rocket PCB Solution Ltd. provides reliable on-sale service.

4. One stop solution for our

pcb fabrication can be provided.

`

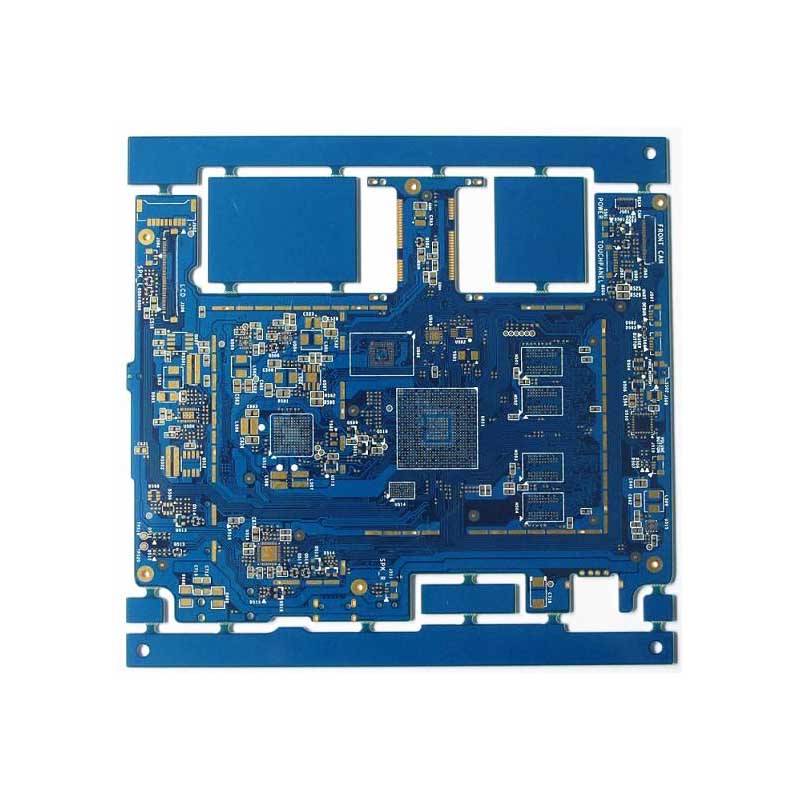

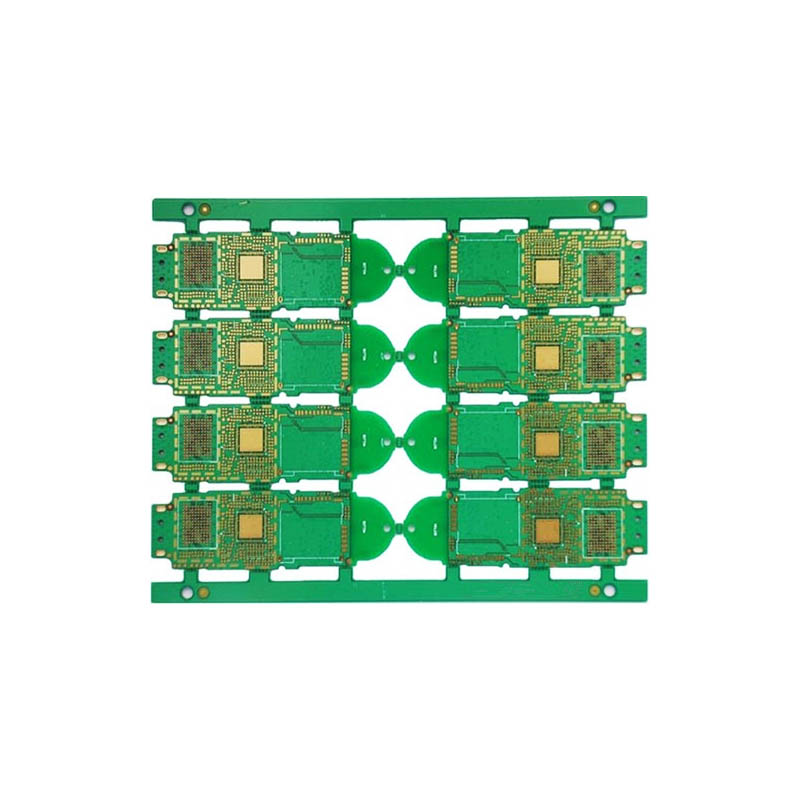

High-density Interconnect PCBs

As one of the most popular products in Rocket PCB Solution Ltd, HDI PCB wins increasing popularity.

FR4

is an essential material for manufacturing the product. Various brands

and sizes are available. It is designed to meet the industry criterion.

Key technologies used in production include LDI, Laser etching.

Supported by 4+N+4 structure capability, HDI PCB is of such

characteristics as improves the wiring density of the inner signal

layer,great help to Power integrity ang singal integrity. HDI PCB is

practical for communication, medical, military, security, industrial,

automotive fields.

Guided by the principle of 'Service

creates value, service wins respect and service builds brand ', we

continue to grow and develop. Welcome people from all walks of life to

consult and cooperate. https://www.rocket-pcb.com

ENGINEERING STRENGTH

Rocket PCB Solution Ltd is passionate about making a difference in the manufacturing industry, so we’re always expanding the research and driving the innovation to find new and practical solutions.

Throughout years of hard work in the manufacturing industry, the R&D team has served as a pillar of Rocket PCB. As time goes by, the R&D team has been expanded to 50 people. With the accumulation of 10 years of experience, each member is skilled at dealing with engineering data by absorbing in advanced technology. All of them are able to provide technical service for customers.

HDI PCB

HDI PCB is one of the most distinguished product among those collections in Rocket PCB Solution Ltd.

It comes with various structures. The design of it caters to varied needs of customers at home and abroad. Impedance control, dense circuit is adopted to produce high-quality HDI PCB. With such parameters as 4+N+4 sturcture, high reliable characterize HDI PCB.

It is UL, SGS, ROHS, ISO9001 certified. Rocket PCB is able to customize HDI PCB based on customers' different needs. For more detailed information on HDI PCB, you may find it at www.rocket-pcb.com/ROCKET PCB SUMMARY

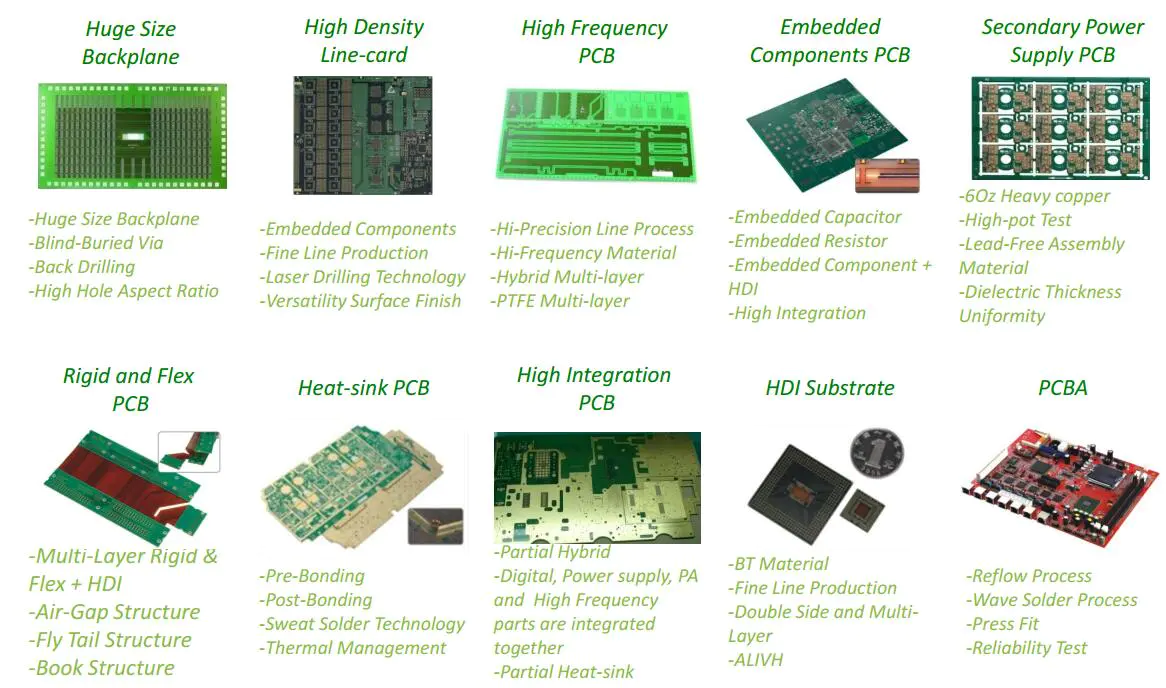

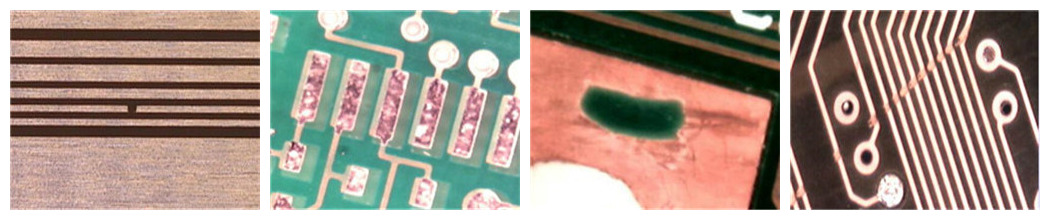

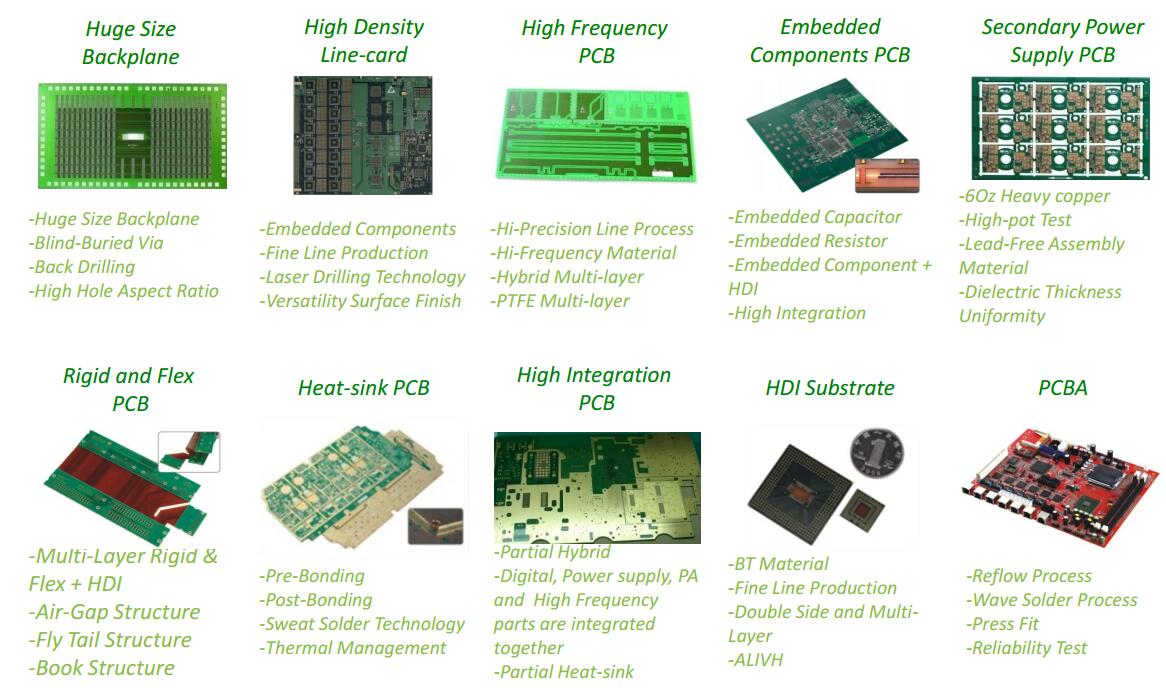

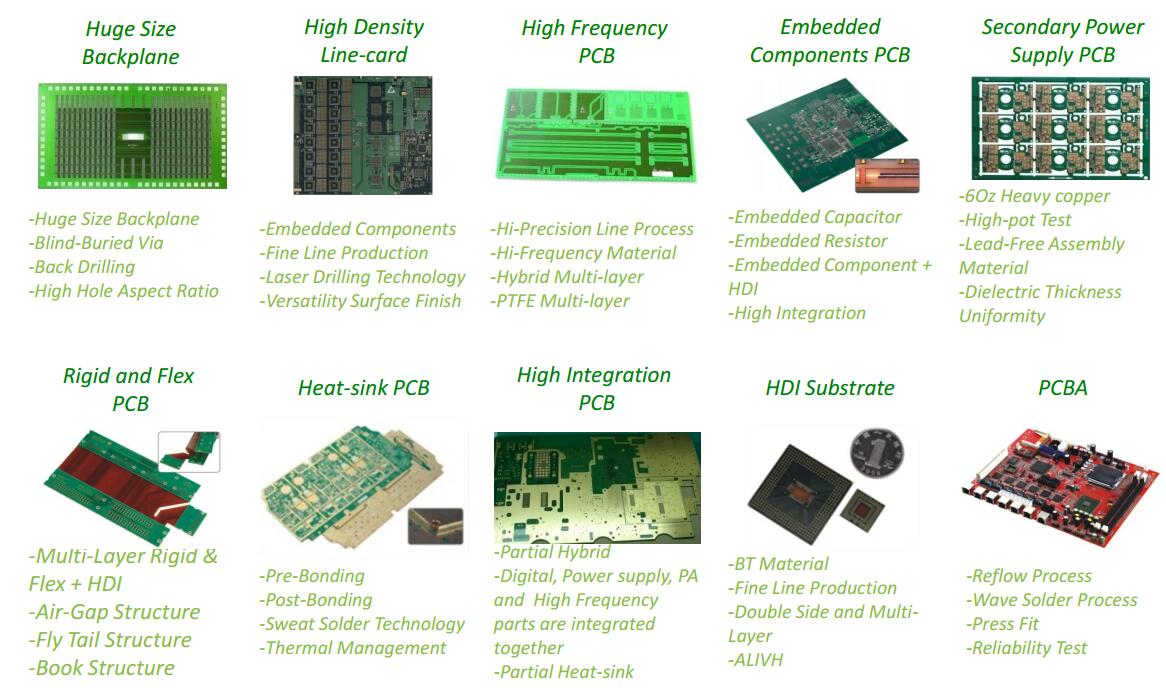

Rocket PCB is an innovative manufacturer focusing on electronic manufacturing. Rocket PCB is dedicated to spending 10 years of efforts advancing itself. We develop, produce and sell numerous successful high-quality products, including rigid, rigid-flex, HDI, any layer, Flex, large-size, embedded, RF, LED, backplane, metal substrate, ceramic substrate, IC structure, high-frequency, heavy copper. High quality and high reliability.

SPECIALIZED MANUFACTURING

Conductive materials and core-to-core bonding

Embedded components

RF connector attachment

Laser direct imaging (LDI)

Laser etching

Laser forming

Multi-level cavity construction

Plated cavities and edges

Composite/hybrid Structures

N+N dual press-fit

Dual-drill

Bonding on metal core

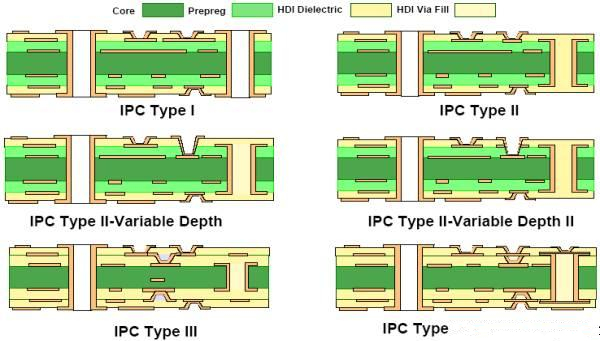

Bulid-up HDI

Long-short and staged gold finger

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF contro

CAPABILITIES

3mil line and space

4mil laser defined vias

6mil chip-on-board

6mil mechanically drilled vias

Conductive and non-conductive via fill

Dual backdrilling

Sequential lamination

Mixed dielectric

Heatsink Bonding

Heavy copper/thermal vias

Blind/buried vias

Stacked and staggerd microvias

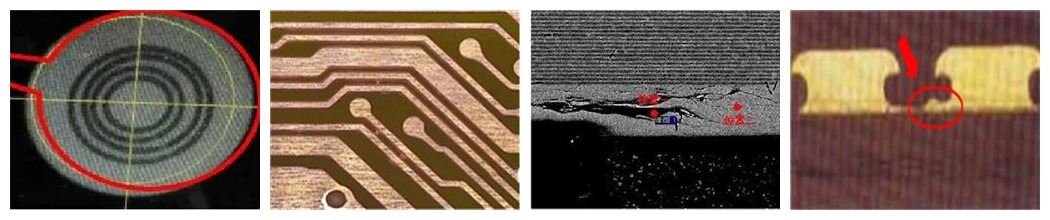

EXTENSIVE ANALYTICAL TESTING![product-Rocket PCB-Rocket PCB manufacturing pcb assembly prototype wide usage-img]()

Design Rules Check(DRC)

Electrical Testing

Automated Optical Inspection(AOI)

X-Ray

Plating thickness testing

Metalized vias inspection

Thermal shock testing

Surface peelability testing

Impedance control testing

100% visual inspection

Solderability testing

Ionic cleanliness testing

Metallographic microscopic analysis

High voltage testing

Insulating resistance testing

FEATURES

PTFE

High speed/low loss

High temperature

Low CTE

Lead-free, HASL, ENIG, EPENIG, Immersion Silver, Tin, Gold finger

Combination surface finished

Copper-filled microvias

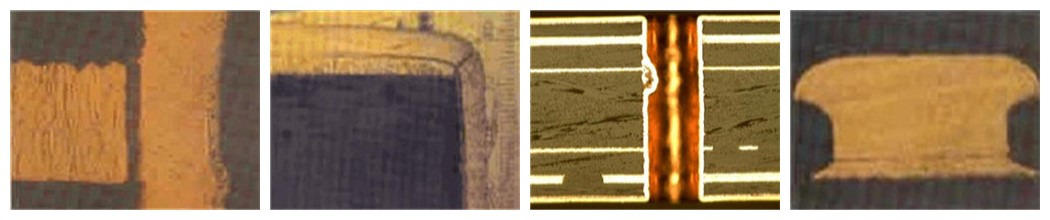

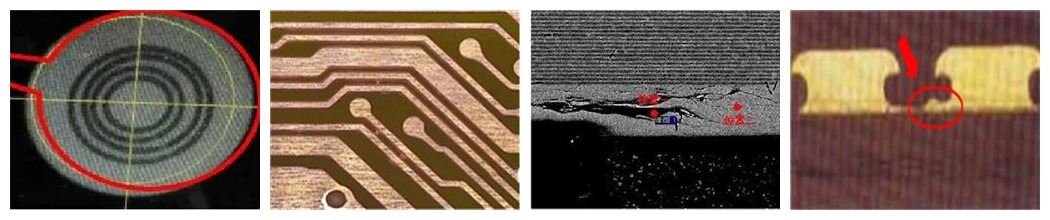

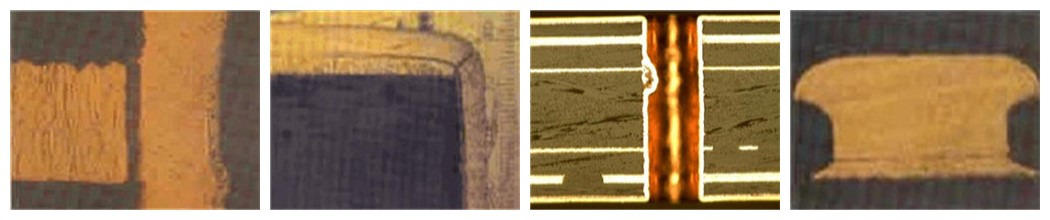

Due to the circuit board industry manufacturing level is uneven, if accidentally selected to the low-end manufacturing plant, there will be poor engineering data processing, old equipment, management confusion, poor parameter control, improper operation of personnel and other process issues, such as the following quality defects.

Drilling Glue Slag Copper Plating Cracking Electroplating Hollow Lateral Erosion

Interlayer Dislocation Micro-Short Delamination B.O. Under Etching

Open Circuit Soldermask Deviation Ink Residual Scratch

These problems will greatly increase the ratio of defective circuit boards, resulting in a sharp increase in the number of rework, insufficient delivery quantity, extended delivery and so on unexpected problems. Therefore, choosing a manufacturer that is highly reliable and of good quality is the perfect choice for you, the quality of the customer circuit board will be guaranteed from the source.

However, In Rocket, with advanced production equipment, excellent PCB solutions and complete testing methods, we have specialists working on their particular fields with the thorough mastery of their particular discipline in each of the production facilities. Training, as well as technical exchanges, are held frequently, tackling problems in key technologies and configuring scheme of equipment and allowing professionals to get up to speed on the essential tools that many organizations value today in the manufacturing industry. Thanks to those above, we have greatly improved the strength and won international reputation.

Advanced Product and Advanced Technology

bg

Product application

Consumer electronics

Automotive electronics

Communications

Energy

Industrial & Instrumentation

IOT/Smart Home

Medical electronics

Security Industry

Rocket PCB Solution Ltd. is a specialized pcb fabrication manufacture and supplier.

2. Constructing the advanced technology is the only way for Rocket PCB to break the bottleneck in HDI PCB industry.

3. We hope to be a pioneer in the pcb assembly industry. Please contact. The assignment of Rocket PCB Solution Ltd. would be to present competent pcb hdi and specialist services to clients. Please contact.