Multilayer circuit board production need to consider what factors

by:Rocket PCB

2020-07-04

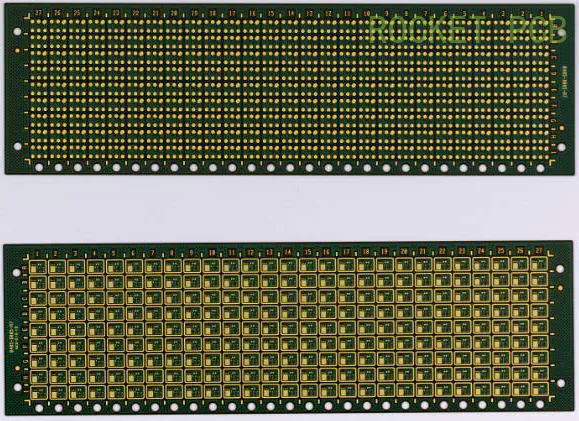

At present, in the field of electronic products processing, multilayer circuit board as one of the important electronic components is necessary.

At present, the PCB circuit board has a variety of types, like the high frequency microwave circuit board PCB plate, etc. Various kinds of printed circuit board has played a certain popularity in the market.

Multilayer circuit board factory for all kinds of plate type have specific processing technology.

But overall, multi-layer circuit board manufacturers are three main aspects need to consider a few times.

1.

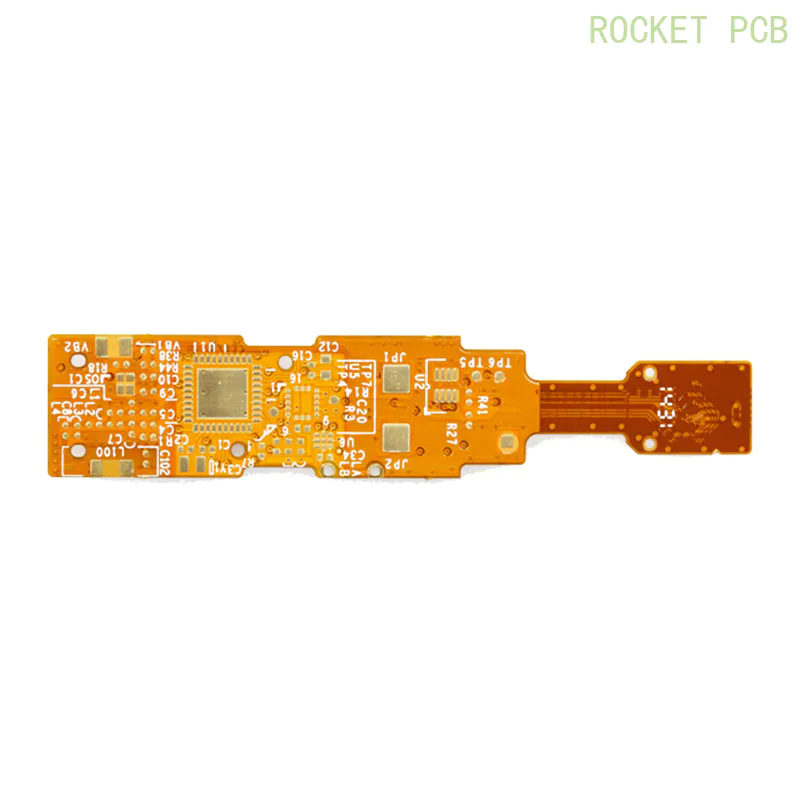

Consider the choice multilayer circuit board making process easy to receive a variety of factors, processing layer, punching process and surface coating treatment process will be PCB circuit board affect product quality.

This on the process environment, therefore, multilayer circuit board production is combined with the characteristics of the production equipment for full consideration, and can according to the difference of different types of PCB and processing requirements of flexible adjustment.

2.

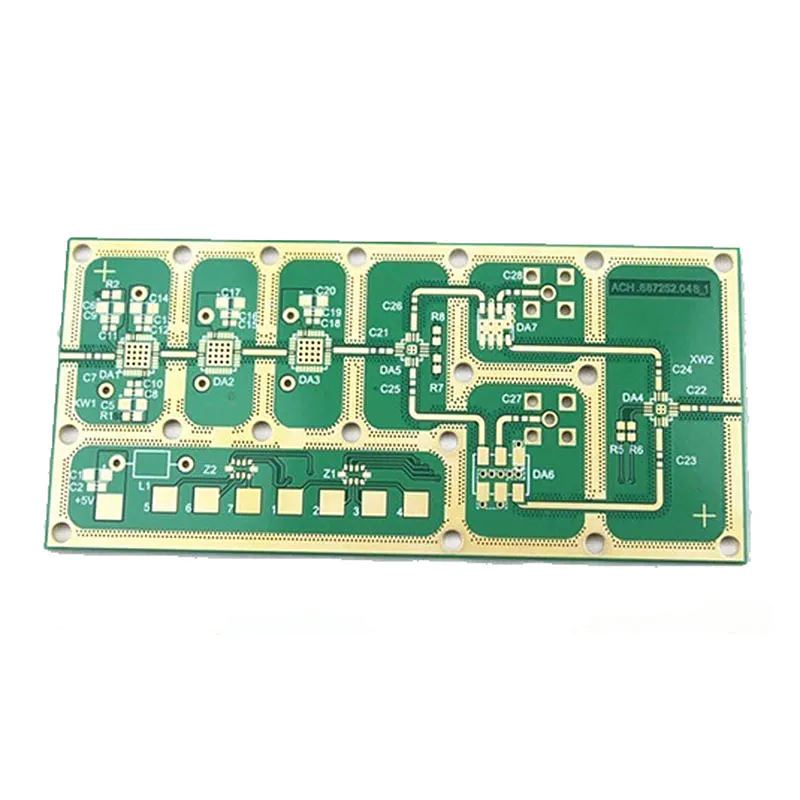

Consider the choice of substrate PCB substrate mainly can be divided into two big kinds of organic materials and inorganic materials, each material has its unique advantage.

Base material type, therefore, the determination of dielectric properties, thickness of copper foil type, slot, machinable features and other performance.

Among them, the surface of copper foil thickness is the key factor that influence the properties of the printed circuit board.

In general, the thickness of the thinner, for the convenience of etching and raising the precision of the graphics have advantages.

BGA boards (

PCB circuit boards)

3.

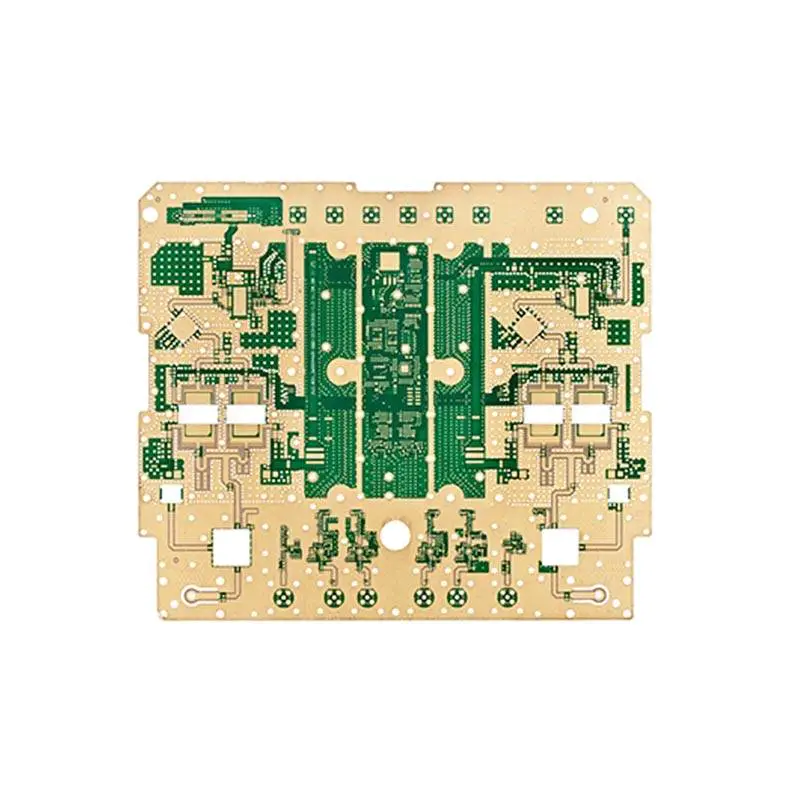

Consider production set of multilayer circuit board production workshop environment is also very important aspect, environmental temperature and humidity control is crucial factor.

If the environment temperature change is too significant, could be lead to base material plate drilling fault.

Environmental humidity if too large, nuclear power have an adverse effect on the performance of the base material with strong water imbibition, embodied in the dielectric performance.

Therefore, circuit board manufacturers in the production, it is necessary to maintain proper environmental conditions.

By the above narrative summary, circuit board processing need to consider when making the selection of base material, consider production environment setting, consider the choice of technological process.

The engineering material at the same time, PCB circuit board processing and blanking method is also an aspect of the choice of need careful with the finished product is closely related to the smoothness of the layout of the circuit PCB.

With technology speeding up in lighting speed, have created quite a name for itself amidst pcb manufacturing services and it happens to have a lot of benefits as well.

More about the most suitable , visit Rocket PCB to get your offer!

pcb making service is produced by Rocket PCB Solution Ltd.’s professional skills in high technology.

We studied how market-leading companies are harnessing data to reshapeRocket PCB Solution Ltd., and explored how they can put data to work for us in ways that create value for our own businesses.

Offering a loyalty program not only makes customers feel valued, but it allows Rocket PCB Solution Ltd. to easily collect important information about customers.

With technology speeding up in lighting speed, have created quite a name for itself amidst pcb manufacturing services and it happens to have a lot of benefits as well.

More about the most suitable , visit Rocket PCB to get your offer!

pcb making service is produced by Rocket PCB Solution Ltd.’s professional skills in high technology.

We studied how market-leading companies are harnessing data to reshapeRocket PCB Solution Ltd., and explored how they can put data to work for us in ways that create value for our own businesses.

Offering a loyalty program not only makes customers feel valued, but it allows Rocket PCB Solution Ltd. to easily collect important information about customers.

Custom message