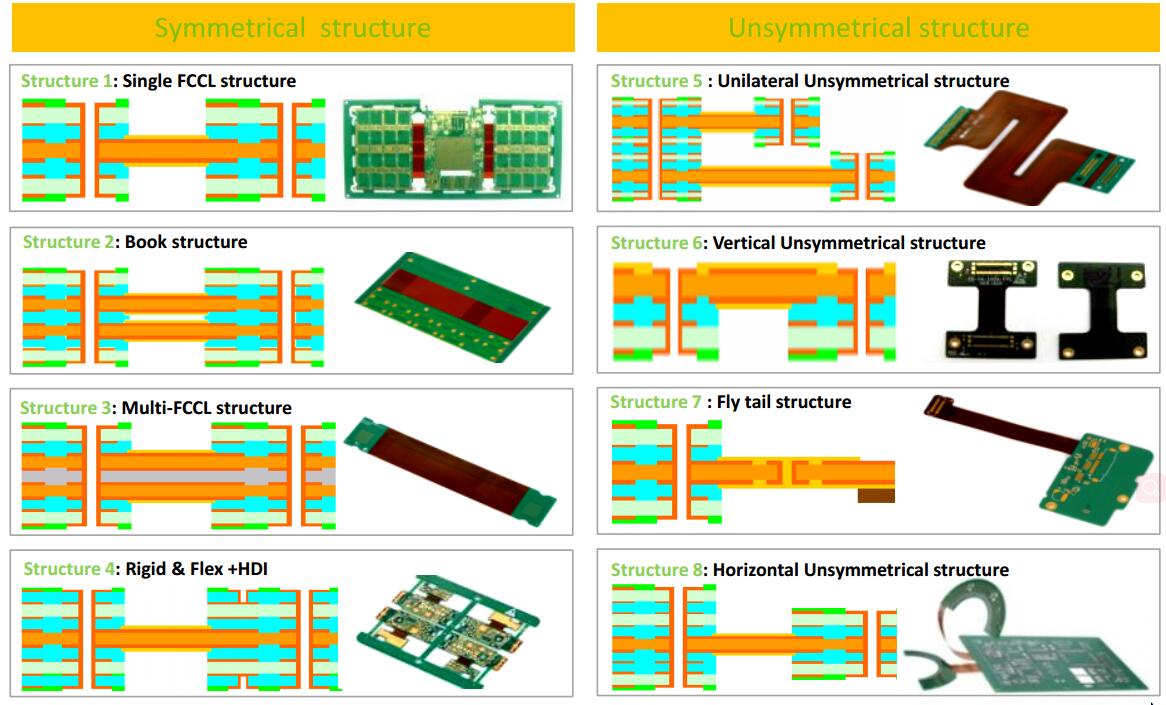

These PCBs

integrate flexible PCBs and rigid PCBs. Because the connection between

layers does not require connectors, they are ideal for digital devices

that are susceptible to noise. In addition, these PCBs can be designed

to create thinner devices with no-connector and three dimensions.

Rigid-flex

printed circuit boards can help you reduce space and ensure that your

products are able to withstand harsh conditions. Also, they are

cost-effective.

A rigid-flex format allows you to use fewer

interconnecting segments to take on more challenges. So the rigid-flex

PCB is a very flexible solution to many design problems. They are

suitable for industries ranging from hearing aids to night vision

mirrors.

Rocket PCB is an innovative manufacturer focusing on electronic manufacturing. Rocket PCB is dedicated to spending 10 years of efforts advancing itself. We develop, produce and sell numerous successful high-quality products, including rigid, rigid-flex, HDI, any layer, Flex, large-size, embedded, RF, LED, backplane, metal substrate, ceramic substrate, IC structure, high-frequency, heavy copper. High quality and high reliability.

SPECIALIZED MANUFACTURING

Conductive materials and core-to-core bonding

Embedded components

RF connector attachment

Laser direct imaging (LDI)

Laser etching

Laser forming

Multi-level cavity construction

Plated cavities and edges

Composite/hybrid Structures

N+N dual press-fit

Dual-drill

Bonding on metal core

Bulid-up HDI

Long-short and staged gold finger

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF control

A wide range of professional manufacturing solutions, can be used for thermal energy (CTE) structural coefficients, thermal challenge design and application, extreme and unique HDI structures, and RF contro

CAPABILITIES

3mil line and space

4mil laser defined vias

6mil chip-on-board

6mil mechanically drilled vias

Conductive and non-conductive via fill

Dual backdrilling

Sequential lamination

Mixed dielectric

Heatsink Bonding

Heavy copper/thermal vias

Blind/buried vias

Stacked and staggerd microvias

Design Rules Check(DRC)

Electrical Testing

Automated Optical Inspection(AOI)

X-Ray

Plating thickness testing

Metalized vias inspection

Thermal shock testing

Surface peelability testing

Impedance control testing

100% visual inspection

Solderability testing

Ionic cleanliness testing

Metallographic microscopic analysis

High voltage testing

Insulating resistance testing

FEATURES

PTFE

High speed/low loss

High temperature

Low CTE

Lead-free, HASL, ENIG, EPENIG, Immersion Silver, Tin, Gold finger

Combination surface finished

Copper-filled microvias

| Design | Manufacturing | Quality Control |

|---|---|---|

| > High TG Rigid material, High reliability Flexible material | > Automatic Pasting Machine | > Check the quality of hole copper plating |

| > Using no‐flow PP and common flow PP | > High temperature lamination machine | > 100% AOI to inspect the desmear result of Micro Via |

| > Partial Coverlay, PTH can’t drill in the adhesive | > High speed drilling machine | > 4 wire low resistance test |

| > PI Conditioner production line | ||

| > Horizontal Desmear and Horizontal PTH | ||

| > Copper via filling plating line and Pulse plating line | ||

| > Vacuum resin filling machine |

Design

> High TG Rigid material, High reliability Flexible material

> Using no‐flow PP and common flow PP

> Dedicated design regulation of no‐flow PP filling copper

> Different squeezed‐out PP lengths use different manufacturing methods

> Partial Coverlay, Coverlay stretch into rigid part with 0.8‐2.0mm

Manufacturing

> Automatic Pasting Machine

> Plasma Machine

> High temperature lamination machine

> Different Rigid‐Flex structures use different buffering material

Quality Control

> Use micro section to check the blister and delamination after lamination

> Squeezed‐out PP of Rigid‐Flex interface less than 1.5mm

> Lead free reflow and thermal stress test, no delamination Plasma Machine

| Design | Manufacturing | Quality Control |

|---|---|---|

| > Different structures have different working panel sizes | > LDI exposure machine | > Check the registration coupon of layers after lamination |

| > Different lamination position methods | > Firstly make flex material pattern, after coverlay lamination to make rigid material pattern | > Check breakout of pad after drilling |

| > Regulation of copper designed in the spare of working panel | > ATP punch machine, INSPECTA target drill machine, divide the boards into different groups to manufacture | > Check soldermask on pad after soldermask process |

| > Registration coupon of layers | > BURKLE high temperature lamination machine | |

| > Soldermask Split exposure machine |

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink