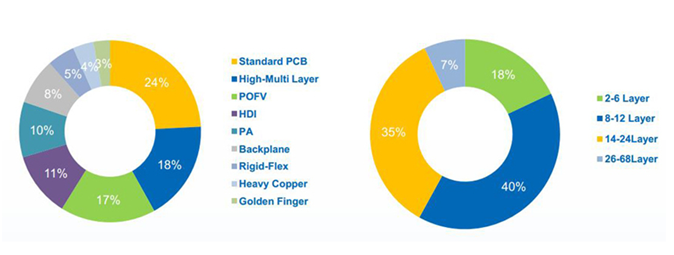

Produced with the latest technology, multi-layer PCB ranks top in the industry

The main material for producing multi-layer PCB is FR4. It comes with

various structures. It caters to the foreign markets. We realized

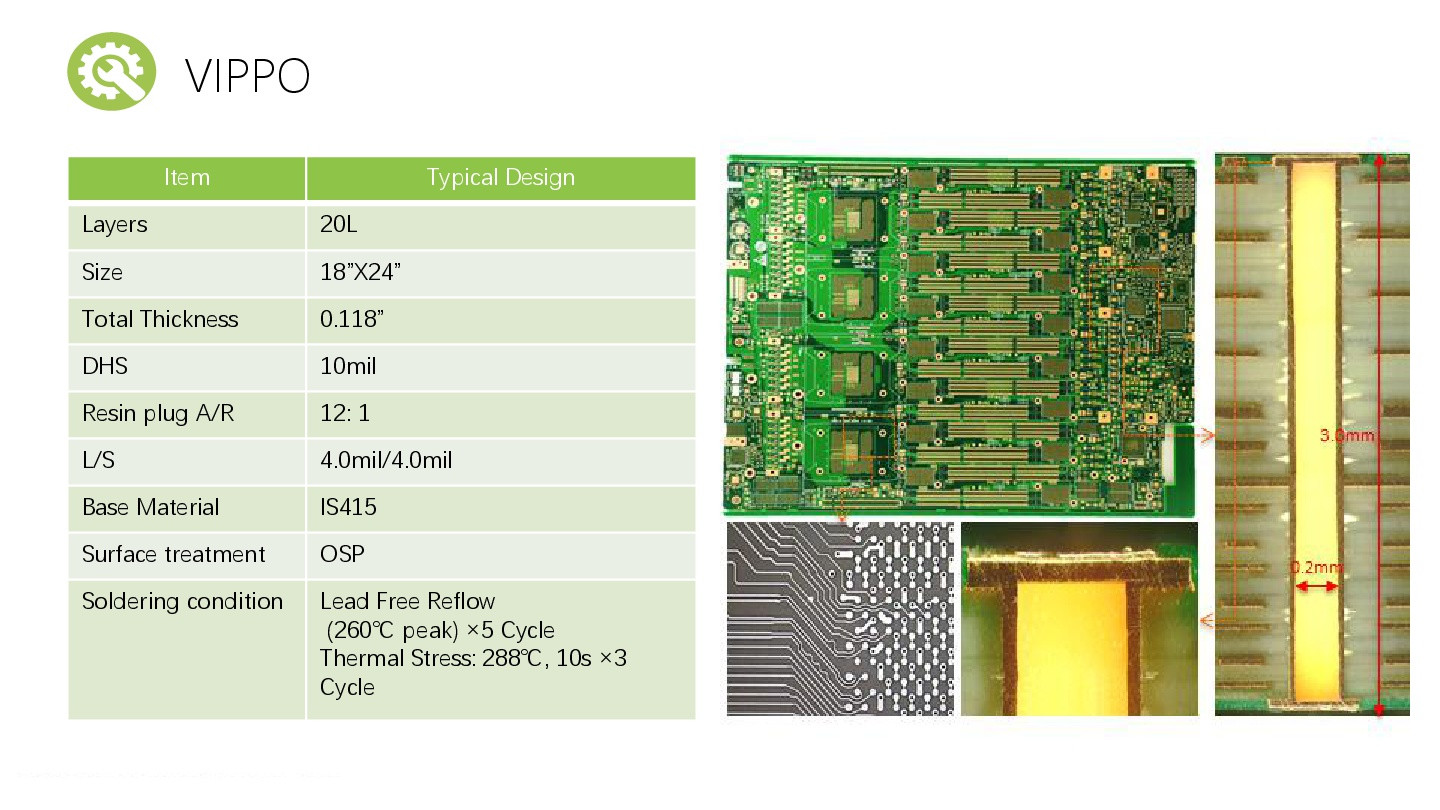

Impedance control, Blind and buried vias, PTH cavities etc in designing

and manufacturing multi-layer PCB. With superior parameters of up to 64

layers, 3mil line and space, plug vias, via-in-pad characterizes

multi-layer PCB. Multi-layer PCB finds a broad range of applications

such as communication, medical, military, security, industrial,

automotive fields. We offer customized solution to you!

For more

detailed information on Multi-layer PCB, you may find it at

https://www.rocket-pcb.com/multilayer-pcb

Rocket PCB Solution Ltd is widely known as a professional supplier in

the electronic manufacturing industry. We have years of experience in

the multilayer PCB HDI PCB segment. Rocket PCB further expands its

range of products including rigid, rigid-flex, HDI, any layer, Flex,

large-size, embedded, RF, LED, backplane, metal substrate, ceramic

substrate, IC structure, high-frequency, heavy copper. High quality and

high reliability.

We have been implementing the policy of 'Service creates value, service

wins respect and service builds brand’. Rocket PCB is always ready for

customers at home and abroad.

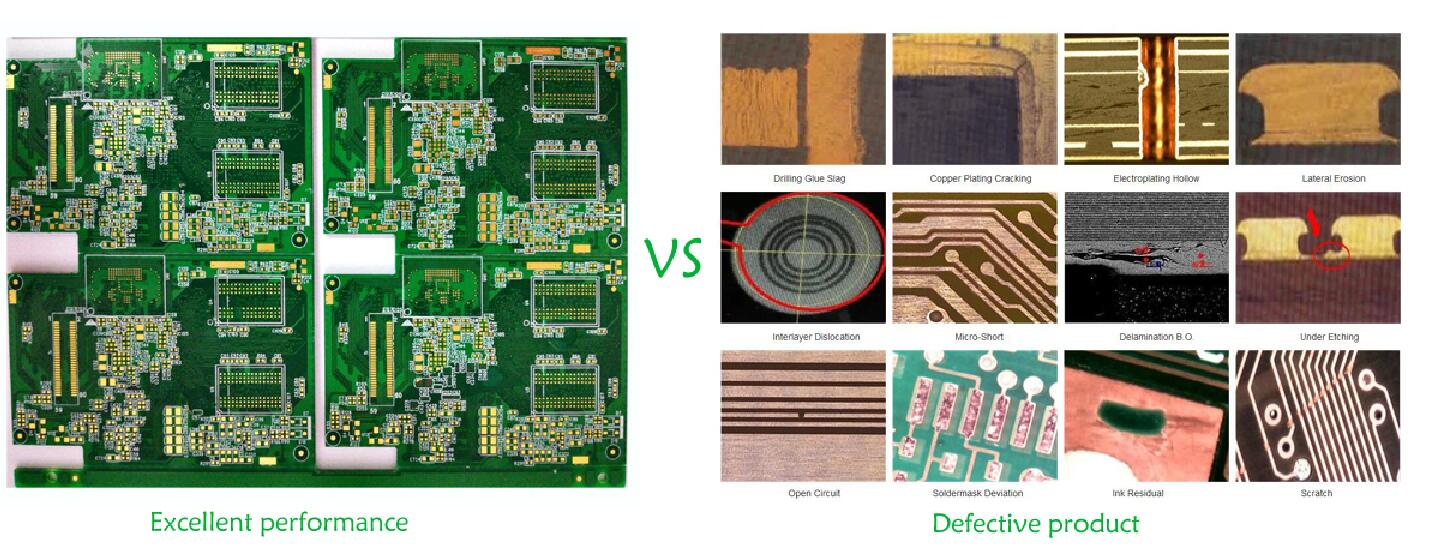

The quality of raw materials is not up to standard

The quality of raw materials is the basic quality of circuit boards. The material itself is not up to standard. The circuit boards made will appear foaming, stratification, board warping and uneven thickness.

Production equipment is not up to standard

With the progress of science and technology, the replacement of PCB production equipment is faster and faster, and the price is more and more expensive. Equipment is to ensure the quality of hardware, increase investment in equipment, so that equipment to achieve high efficiency, stability is the fundamental way to improve the quality of circuit boards. As a result, some small PCB factories are unable to purchase expensive equipment, which ultimately leads to the poor quality of FPC products.

Production technology is not up to standard

Each process of PCB production must be carried out in accordance with strict production process, and each process must be equipped with corresponding inspection equipment. These process parameters and equipment can guarantee the stability of PCB quality. Because the production technology is not up to the standard, many PCB factories only have low prices, resulting in the quality of the production line board is not up to standard.

The first point is the circuit design

The PCB with good quality must have reasonable circuit design. Whether double-layer or multi-layer board, it must have accurate line control and reasonable trace trend, in order to avoid the slow response due to redundant lines, that is, line width, line thickness, line spacing meet the requirements, so as to avoid line heating, circuit breakage, and short circuit.

The second point is the appearance

The PCB circuit board with good quality not only has a neat and smooth surface, but also basically does not appear the phenomenon of bending or uneven. The copper surface is not easy to oxidize, and there will be no cracks or scars, ink falling off.

The third point is the heat resistance of the product

This point should be observed personally, PCB circuit boards are assembled in their own products. If they can withstand the instantaneous high temperature produced by welding and the copper foil is not easy to fall off under high temperature, it shows that the PCB circuit boards have good heat resistance and good quality.

The fourth point is the expansion coefficient

PCB circuit boards can produce drastic expansion or contraction in hot and cold environment. If the expansion coefficient is small and the thermal and cold environment has little influence on PCB circuit boards, the quality of PCB circuit boards is good and the components on PCB circuit boards will not be damaged.

Yield Advantages

Strong fabrication strength, can meet the bulk needs of different clients

> The factory invested heavily in importing foreign advanced PCB production equipment, such as Burkle laminator, Mitsubishi laser drill, Hitachi mechanical drill, Japan screen automatic exposure machine, LDI, AOI etc, highly automated production.With a monthly output of up to 250,000 square meters.

> Our suppliers have formed a complete production process, which is becoming more specialized, modern and large-scale, has signed long-term strategic cooperation agreements with well-known enterprises at home and abroad.

> Our superb quality and leading market position are guaranteed under the ISO9001, ISO14001, ISO/TS16949, OHSAS18001, ISO/IEC27001, UL, SGS, ROHS system with our strong technical development drive. We also insist on adopting 5S methods, Lean and Six Sigma quality systems.

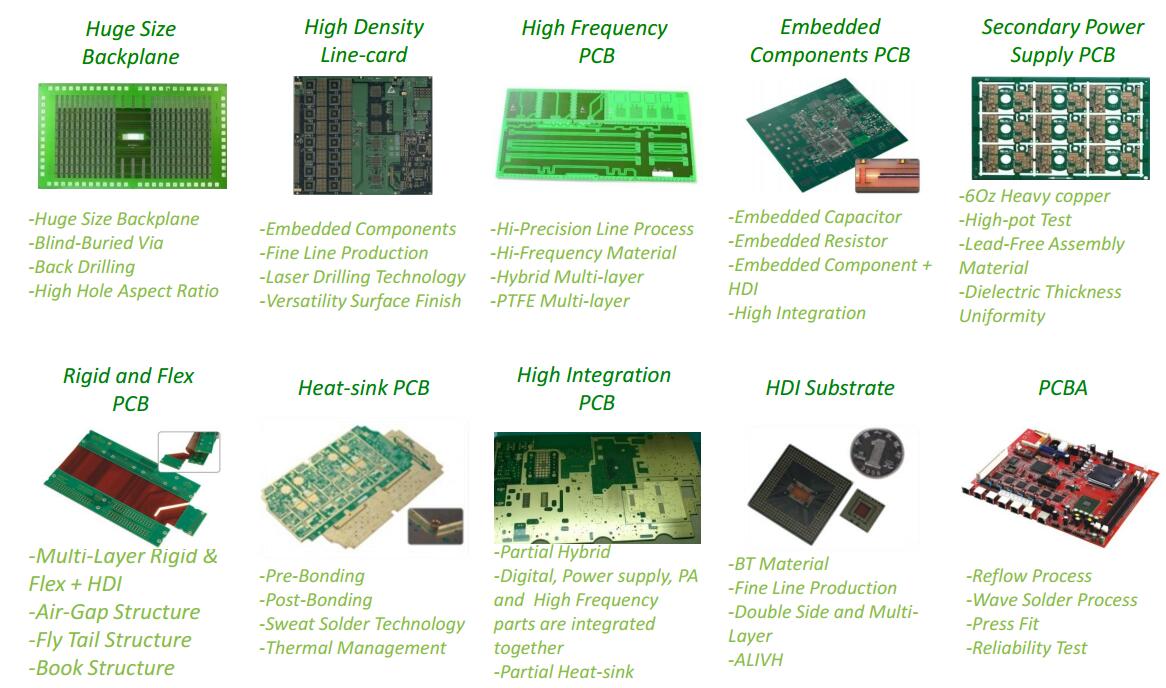

Technical Advantages

> We provide real-time and in-depth technical support. Tailor-made application solutions, like high speed, high capacity and high frequency, press-fit, heat-sink solutions.

> Free DRC and DFM

> Rapid feedback on the layout,build-up, panels, impedance, material selection, design rules, manufacturability, costs of different solutions, use of micro vias, gold plating, special laminates, etc.We always put the best interests first when providing innovative solutions for manufacturing customers’ products

> Rocket provides industry-leading support to our customers so that we can help them grow

Advanced Product and Advanced Technology

Service Advantages

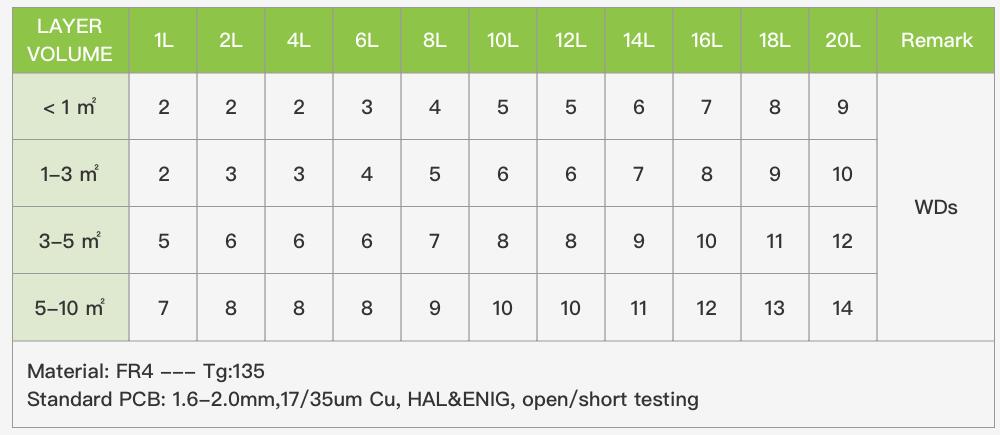

> 24 hours online tech support and fast quote in 2 hours for standard board

> A number of production lines meet the request of mass production and fast turn around of small batches and various prototype PCBs

> Expedited production line for prototyping double-sided PCB up to 24 hours, 4 layers 48 hours, 6 layers 72 hours etc.

> Mass production of double-sided PCB 5-6 days lead time, multi-layer PCB 7-9 days.

> DHL, Fedex, TNT, UPS Express delivery, fully meet the customer's time requirements, on time delivery more than 99%

> Strict production and testing, 100% outgoing pass rate.

> Provide 1-64 layers of different thickness, different materials, different processes of product customization, of which the CCL using A-class raw materials, high quality assurance.

> Unlimited PCB capabilities,we provide various and advanced technology PCBs include rigid, FPC, rigid-flex, metal core, microwave/RF, HDI, any layer, heavy copper, large-size, embedded, LED, backplane, ceramic substrate, IC substrate, high-frequency, high-density and high-performance PCB.

> Eight major surface treatment technology and high-quality ink printing, beautiful and reliable.

> Dozens of tests such as open/short circuit testing( ET test), AOI, X-ray, impedance testing, solderability testing, thermal shock testing, metallographic micro-slicing analysis, halogen-free testing, etc.Rocket PCB supply chain meticulously practices all-around quality management and actively introduces and implements multi-domain system management. We have successively obtained ISO9001, ISO14001, IATF16949, OHSAS18001, ISO/IEC27001, ISO13485 and AS9100 certifications.

Compared with other low-end manufacturers, Rocket PCB has unparalleled advantages. Low-end manufacturing factories are facing various quality defects due to outdated equipment, confused site management, improper operation, poor quality control, insufficient skills of engineers and inadequate process control.

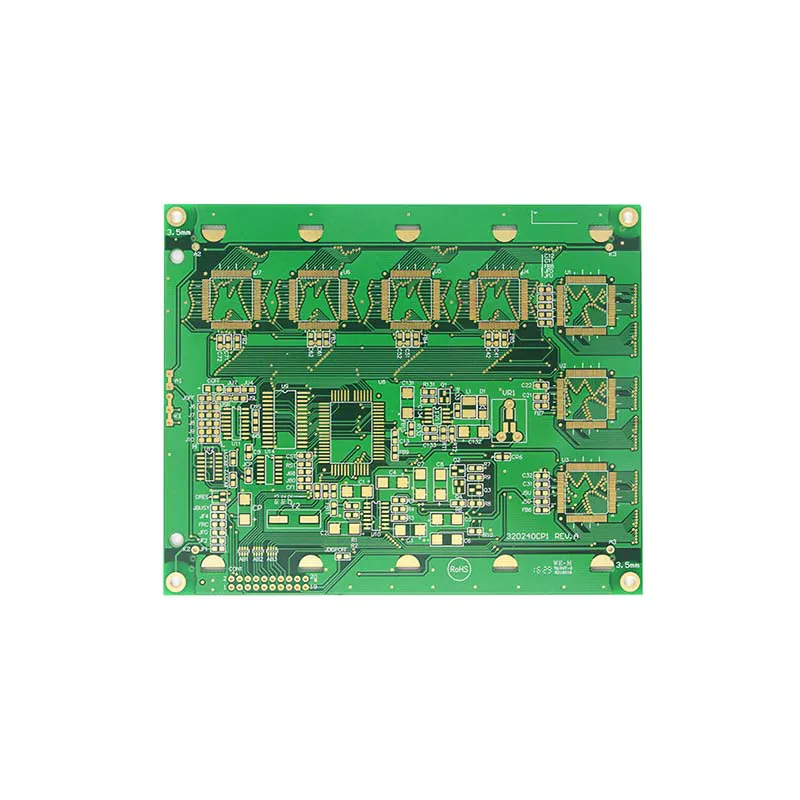

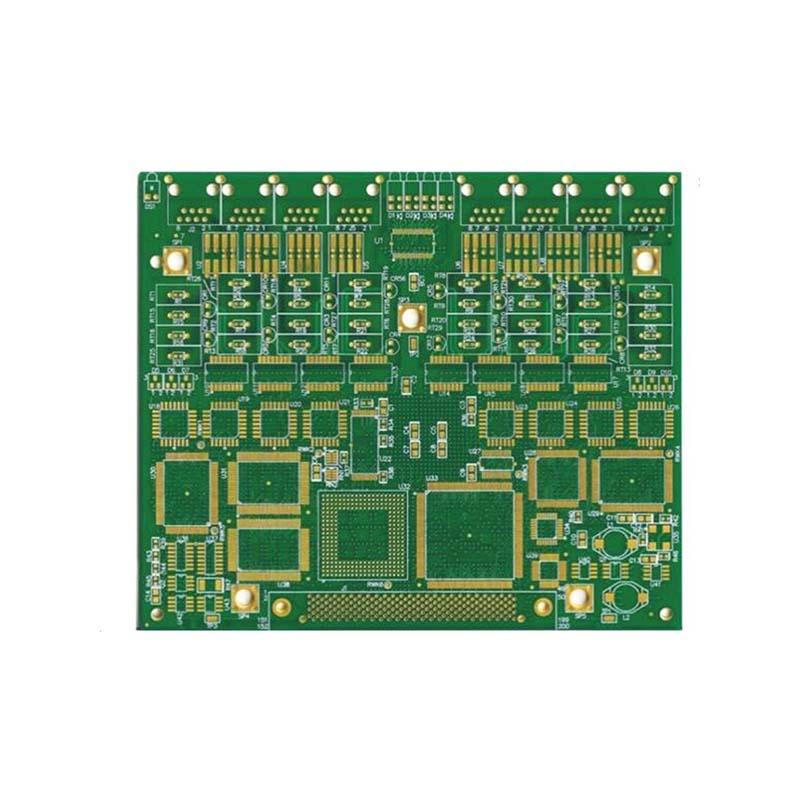

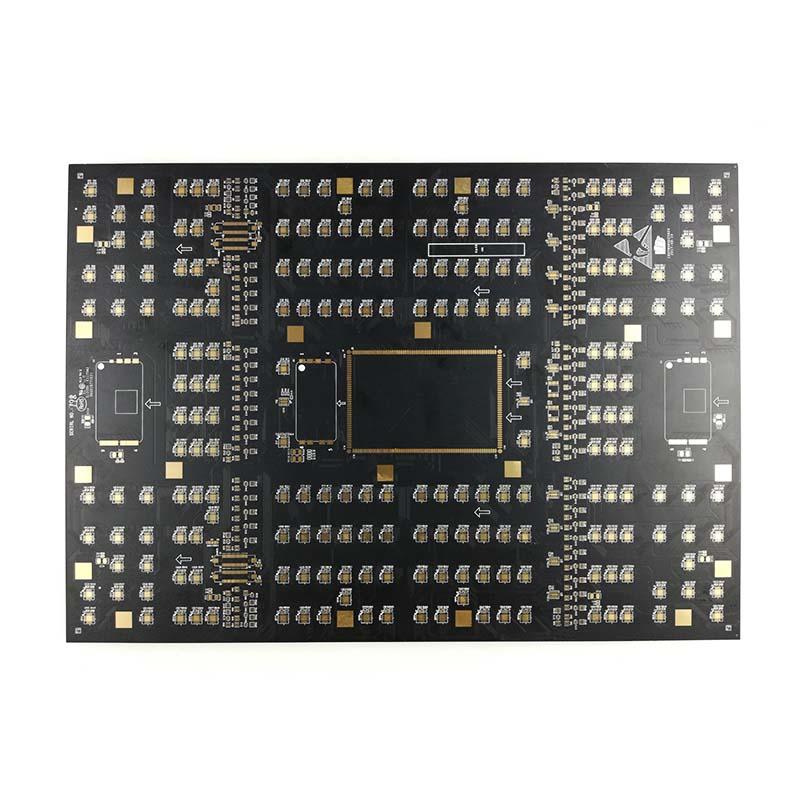

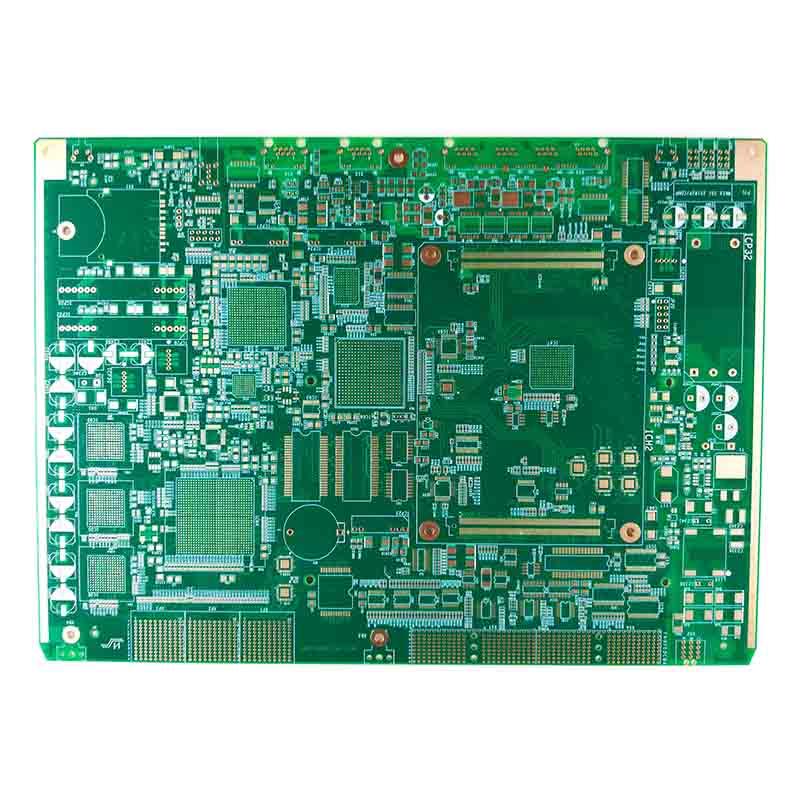

Multilayer PCB Product Case

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink