Flexible PCBs have some very amazing benefits including:

Reduced space and weight: Most of the advantages associated with flexible PCBs come from their small volume and weight. In fact, the use of flexible PCBs can reduce space by more than 50% and reduce weight by more than 95% while maintaining the function and reliability of the circuit.

Durability: The flexibility of the PCB, the reduced weight and the reduced number of interconnections enable them to handle changing external forces and improve their ability to resist shock and vibration.

Signal integrity: Flexible PCBs can work in a variety of environments and their signals will always run smoothly regardless of external conditions, which proves the signal reliability of the PCB.

Higher density: thin layers and smaller components mean flexible PCBs can support higher circuit density.

Minimize error: Flexible PCB reduces wiring errors due to the elimination of mechanical connectors and small options in assembly methods.

Low cost: Because flexible PCBs manufacturing involves fewer assembly steps, they tend to be relatively inexpensive.

Heat dissipation: The thinner material of the flexible PCB allows for a larger surface area and volumetric ratio, thus improving heat dissipation.

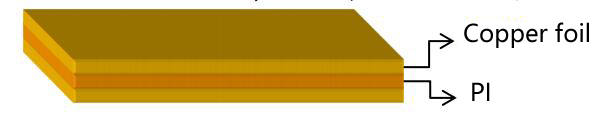

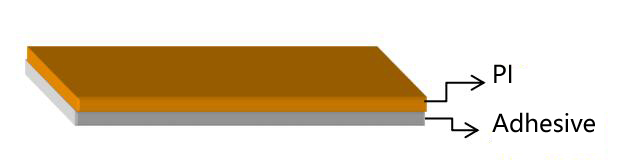

Without Adhesive

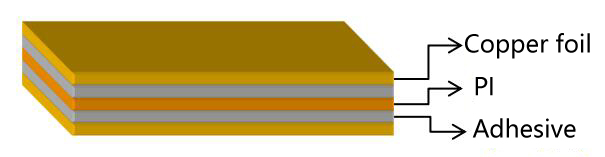

Flexible board classification

Flexible board is usually classified according to the number and structure of conductors as follows:

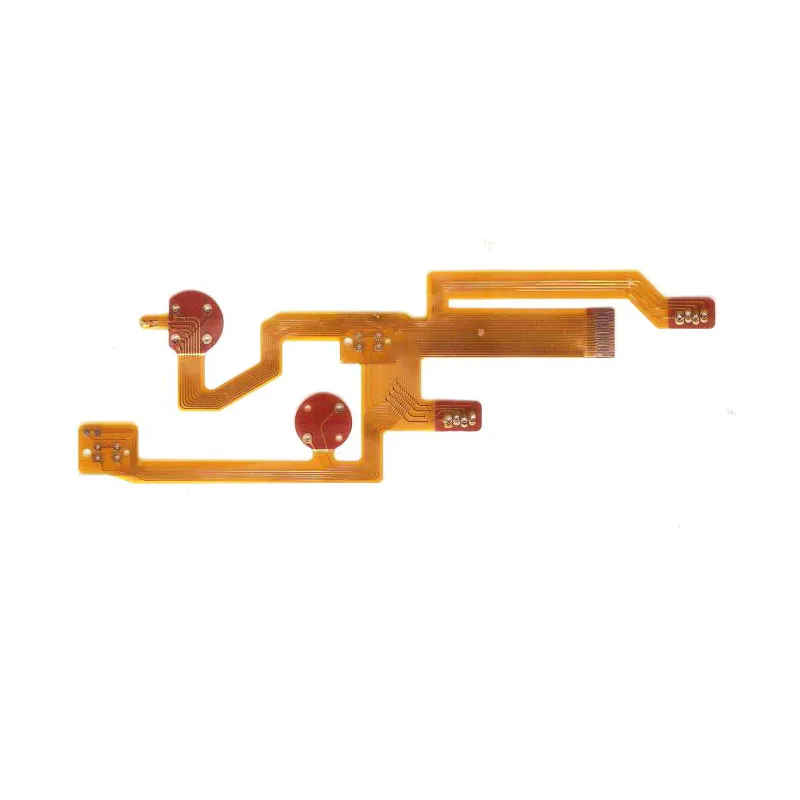

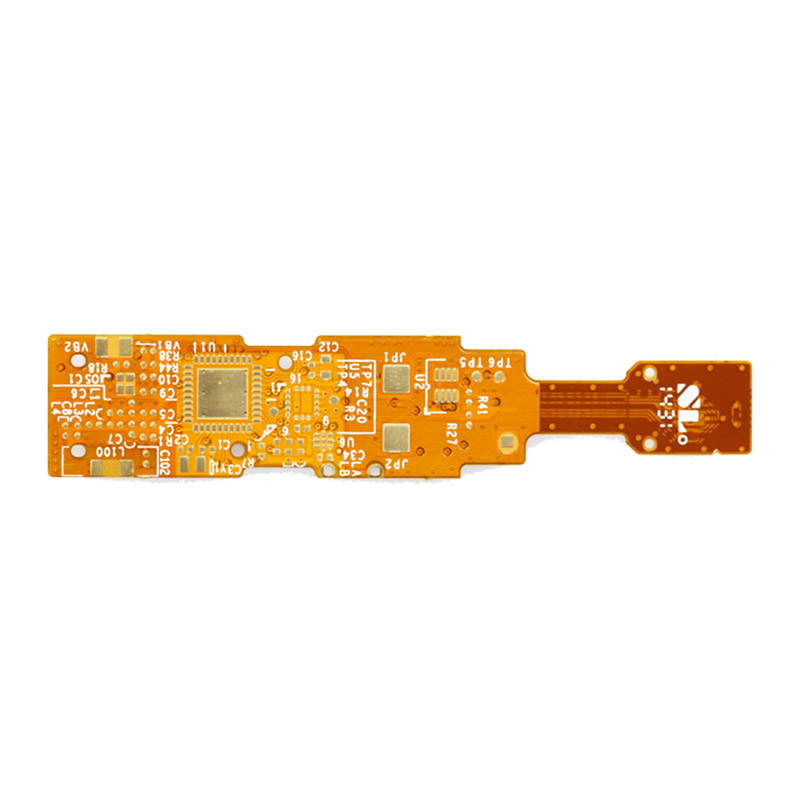

Single-sided Flexible Board

A single-sided flexible board has only one layer of conductor, the surface with or without a covering layer. The insulating substrates used vary with the application of the products. Generally used insulation materials are polyester, polyimide, PTFE, flexible epoxy-glass cloth, etc.

One-sided flexible board can be further divided into the following four categories:

1) Flexible PCB without covering layer

The conductors of this flexible PCB are on the insulating base material, and there is no covering layer on the conductor surface. Like the usual one-sided rigid PCB. This kind of product is the cheapest one, usually used in non-critical and environmentally friendly applications. Its interconnection is realized by soldering, fusion welding or pressure welding. It was often used in early telephones.

2) Flexible PCB with covering layer

Compared with the former type, this kind of board only has an additional layer of cover on the conductor surface. When covering, the pad should be exposed. It is one of the most widely used in a single-sided flexible PCB and widely used in automotive and electronic instruments.

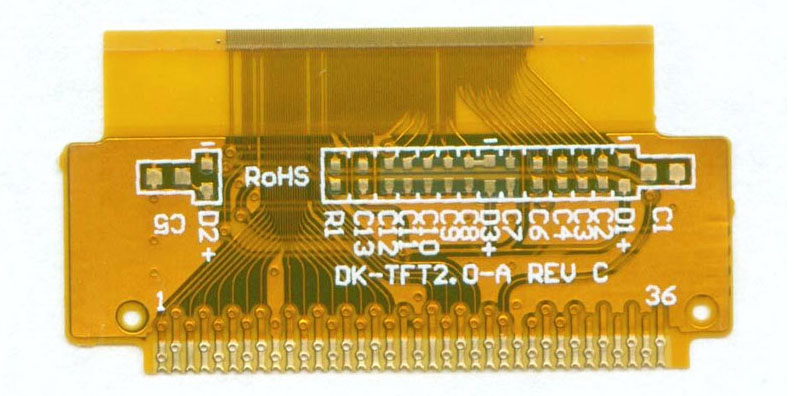

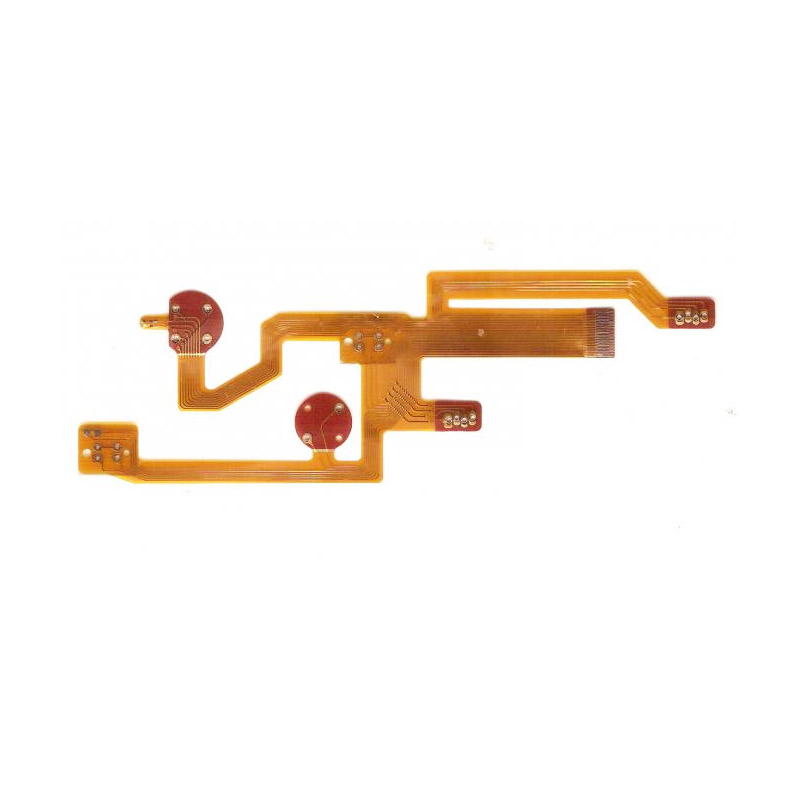

Double-sided flexible PCB

Double-sided flexible PCB has two conductors. This kind of double-sided flexible PCB has the same application and advantages as single-sided flexible PCB. Its main advantage is to increase the wiring density per unit area. It can be divided into:

a. without PTH hole and no covering layer;

b. without PTH and with covering layer;

c. with PTH and no covering layer;

d. with PTH and covering layer.

Double-sided Flexible PCB without Covering Layer is Less Used

Multilayer Flexible PCB

Flexible multilayer PCB, like rigid multilayer PCB, can be made into multilayer flexible PCB by using multilayer lamination technology. The simplest multi-layer flexible PCB is a three-layer flexible PCB formed by two copper shielding layers on both sides of a single PCB. The three-layer flexible PCB is equivalent to coaxial or shielded conductors in electrical characteristics. The most commonly used multi-layer flexible PCB structure is a four-layer structure, which implements interlayer interconnection with PTH holes. The middle two layers are generally the power layer and the ground layer.

Multilayer flexible PCB has the advantage of light weight and excellent electrical properties, such as low dielectric constant. Multilayer flexible PCB board made of polyimide film is about 1/3 lighter than rigid epoxy glass cloth multilayer PCB board, but it loses the excellent flexibility of one-sided and two-sided flexible PCB. Most of these products do not require flexibility.

> We offer the most effective and flexible solution for you

As a leading and professional PCB maker, Rocket PCB can closely integrate manufacturing, logistics and supply chain management. Therefore, PCB design, PCB manufacture and PCB assembly can be accomplished faster and cheaper without compromising our high quality standards. We provide real-time in-depth technical support and customized application solutions, such as high-speed, large capacity, high frequency, hybrid structure, thermal management and metal base solutions.

> Focus on the customer first

We always give priority to customers and provide timely and effective services. Excellent customer service is a challenge for contract manufacturers, original equipment manufacturers and design companies. Regardless of the size or complexity of the order, Rocket PCB is committed to filling this gap in the industry through active and continuous communication with customers. Rocket PCB knows that the only way to achieve this goal is to provide the highest quality products at the most competitive prices. In providing innovative solutions for our customers'products, we always put the greatest interests first. Finally, Rocket provides our customers with industry-leading support to help them grow.

> Unlimited PCB capabilities

You don’t need to find a new and uncome-at-able PCB supplier due to our unparalleled strength. We provide various and state-of-the-art PCB including rigid, FPC, rigid-flex, metal base, microwave, HDI, any layer, large-size, embedded, RF, LED, backplane, ceramic substrate, IC substrate, high-frequency, high-density and high-performance PCB.

> Comprehensive Engineering solutions

Elite engineers with many years of industry experience provide you with free and comprehensive engineering review and support to ensure that Gerber documents are completely correct before they are produced. To achieve tremendous cost-effectiveness for you, so that your PCB products can faster from conceptual design to mass production.

> High-quality Assurance

"High quality" is always the soul of rocket PCB production. Providing satisfactory products and services is our goal. With strong technical development force, the company has guaranteed the excellent quality and leading market position of products through ISO 9001, ISO 14001, ISO/TS16949, OHSAS 18001 and ISO/IEC27001 systems. We also adhere to the 5S approach, Lean and Six Sigma quality systems.

> Reduce Your Costs

We

can save your PCB cost through our comprehensive solution, which is

specially suited to your needs. In addition to cost savings from PCB

manufacturing, Rocket PCB can also save you costs through our design and

pre-engineering services. Most of our customers tell us that this

benefit is the most important reason for maintaining a long-term

relationship with us.

> Material Stock Advantage

We maintain a large inventory of PCB materials like Rogers, Teflon(PTFE), Nelco so that we can realize a fast service to a wide range of PCB applications. The material shortage is not a problem for us.

> Shorten Time to Market

Whether your business focus is research, development, innovation or business development, your decision to work with Rocket PCB allows us to provide you with PCB manufacturing, component procurement, programming, testing and final assembly, so that you can focus on the areas you are best at. Standard project quotation within 2 hours, 24 hours of rapid PCB prototyping, 24 hours of online technical support, on time delivery, so that your PCB purchase worry-free. The rapid turn around is the basis of our strong competitiveness.

Copyright © 2026 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink