clapper led candle

by:Rocket PCB

2019-08-30

Three years ago, I saw \"My New Flame\" by Moritz Wald Meyer, INGO MAURER and TEAM 2012 at the museum gift shop and fell in love with the idea.

I want to recreate something fascinating, enjoyable, fully functional, fun, but a little bit distorted.

Of course I can\'t compare to their beautiful works of art.

So I created the Clapper version of an LED candle.

Clap twice and turn the candle on or off.

The Clapper feature is optional and can be turned on or off if included in the build.

Alternatively, this feature can be completely omitted in the build.

There are seven such candles and night lights around my house.

I plug them into the 5 VDC phone charger to power the device and to Li-Ion battery.

A single charge can last about 18 hours, making them ideal for emergency lighting.

Note: a candle with a lid on the right side of the video is not a candle for the popapper.

Parts required for the project: with Clapper (Optional)

: Tools: the tool path for cutting acrylic resin can be created using the PDF vector diagram provided.

Each PDF file contains the top, bottom, sides, and a small rectangle that is used as an interval below the sound module.

If you\'re building non-Clapper (without Sound)

The version of this LED candle.

I cut most of the parts with 1/8 vertical mill and ran a finishing mill with 1/16 vertical mill.

For narrow slots on the side and top, 1/16 vertical grinding is required.

The mounting holes are manually positioned and drilled manually.

Some holes should be drilled before assembly.

For example, install the holes of the PowerBoost board.

Sand and test fit all the pieces.

I suggest using Plast-I-

Weld to glue the pieces together.

Note: the diameter of the top and bottom must be with the inner diameter (ID)

The resin candle body you purchased.

The basic LED candle circuit consists of battery, switch, power supply and candle printed circuit board (PCB)

Use LED charging matrix, charging matrix driver and Arduino Pro Mini 5 VDC.

You can see the Assembly version of the candle circuit board on it.

The only connection to this PCB is the 5 VDC provided by the power supply.

The battery is connected to a PowerBoost power supply that can be Li-

Ion batteries and provide protection for low voltage batteries.

The power supply also provides a way to turn the candle on or off by switching to ground EN connection.

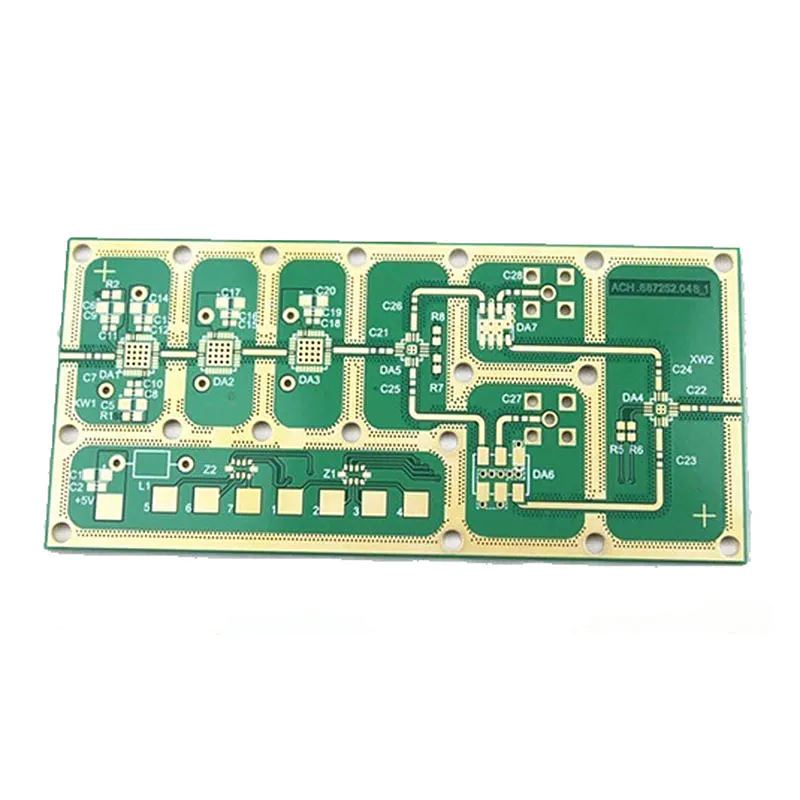

The Clapper PCB includes Solid State Relays (LCB710)

And single chip (ATTiny85)

Process the signal of the sound module and control the power supply of the candle PCB.

ATTiny85 is programmed to listen to two loud sounds at the same time and turn the relay on or off.

Unfortunately, this configuration cannot distinguish clapping from any other loud sound, so the circuit will activate if any two loud sounds are heard at the same time.

I installed a DIP-

8 outlets on the Clapper PCB for easy installation or removal of attiny85.

All other components can be welded to the circuit board.

Connect pins 1 and 2 of J1 for normal operation.

Second, connection &-

Pin and &-of Cl Board PCB &-

Candle PCB.

Connect the 5 v and GND of the PowerBoost power supply &-

Connection of \"clapper plate of\" pressurized water reactor.

Connect the mini Toggle Switch SPDT to the \"CLAPPER\" connection.

Connect the lever of the switch to C and the other two as needed.

Finally, connect the VCC and GND of the sound module &-

Output of \"snd mod\" and output connection of Clapper PCB.

Attached is the Gerber file I created with KiCad for ordering two printed circuit boards.

I recently ordered 10 candle flame pcb for $5.

As it happens, I ordered twice the motherboard for half the price of my original 2016 order.

Adafruit offers a tutorial on using LED charity matrix and drivers in animated flame pendants.

I used the same sketch on Arduino Pro Mini but changed the data.

The flame I made.

This tutorial provides everything you need to get started with LED Charlies.

ATTiny85 used the sketch I found on Henry\'s bench

Arduino sound detection sensor: tutorial and user manual.

This page will guide you through the configuration and tuning of the sound sensor module and Arduino. My sketch (

ClapperCandle_V2. ino)

Because ATTiny is almost the same as his example.

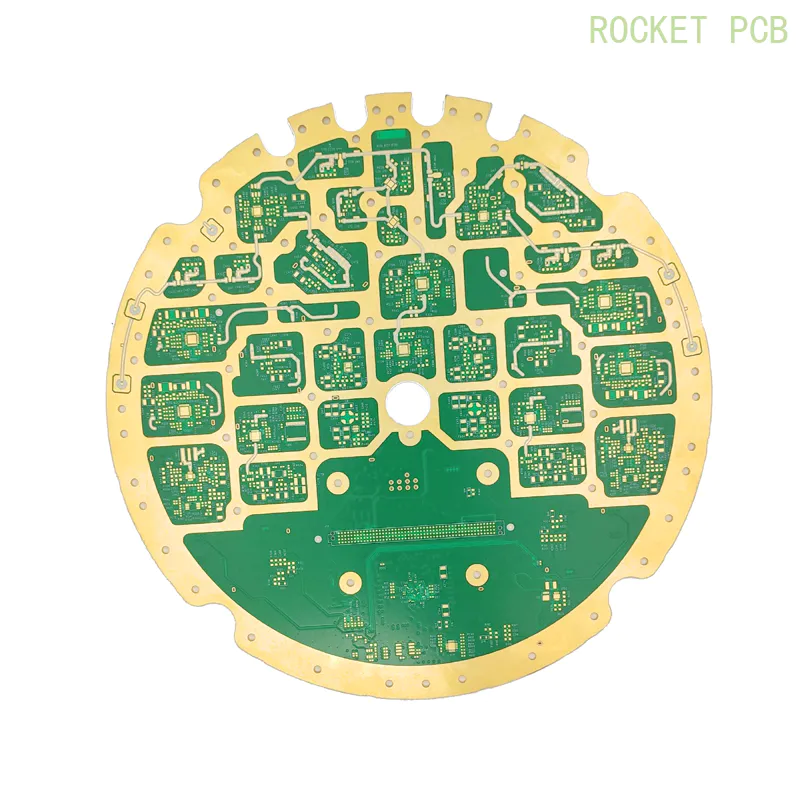

After the Pcb assembly is completed, it can now be installed on the acrylic base.

As mentioned earlier, drilling is recommended before bonding.

If you are building the Clapper version, the previously cut rectangular spacers are located on the side of the sound module installation position.

This can be seen in the photo above.

The Clapper PCB is installed below the sound module and on the same side.

Connect the PowerBoost 500 power supply to the battery and the main power switch, and if the Clapper PCB is not used, connect the 5 VDC and GND directly to the \"pwr in\" connection of the candle PCB.

Otherwise, connect the output voltage of the power supply &-

PCB.

Connect the SPDT toggle switch to the \"CLAPPER\" connection as indicated earlier and connect the sound module to the \"snd mod\" as indicated earlier \".

Respective connections (+ -TRG)

The PCB of the Cl board is connected to the candle PCB.

The TRG connection is not connected to anything.

Check your line against the schematic, when you are ready to install the battery and turn it on.

Resin candles require a micro USB cable to be connected to the holes in the power supply.

So I installed these on my CNC and cut a hole at the right distance from the bottom. ENJOY!

I want to recreate something fascinating, enjoyable, fully functional, fun, but a little bit distorted.

Of course I can\'t compare to their beautiful works of art.

So I created the Clapper version of an LED candle.

Clap twice and turn the candle on or off.

The Clapper feature is optional and can be turned on or off if included in the build.

Alternatively, this feature can be completely omitted in the build.

There are seven such candles and night lights around my house.

I plug them into the 5 VDC phone charger to power the device and to Li-Ion battery.

A single charge can last about 18 hours, making them ideal for emergency lighting.

Note: a candle with a lid on the right side of the video is not a candle for the popapper.

Parts required for the project: with Clapper (Optional)

: Tools: the tool path for cutting acrylic resin can be created using the PDF vector diagram provided.

Each PDF file contains the top, bottom, sides, and a small rectangle that is used as an interval below the sound module.

If you\'re building non-Clapper (without Sound)

The version of this LED candle.

I cut most of the parts with 1/8 vertical mill and ran a finishing mill with 1/16 vertical mill.

For narrow slots on the side and top, 1/16 vertical grinding is required.

The mounting holes are manually positioned and drilled manually.

Some holes should be drilled before assembly.

For example, install the holes of the PowerBoost board.

Sand and test fit all the pieces.

I suggest using Plast-I-

Weld to glue the pieces together.

Note: the diameter of the top and bottom must be with the inner diameter (ID)

The resin candle body you purchased.

The basic LED candle circuit consists of battery, switch, power supply and candle printed circuit board (PCB)

Use LED charging matrix, charging matrix driver and Arduino Pro Mini 5 VDC.

You can see the Assembly version of the candle circuit board on it.

The only connection to this PCB is the 5 VDC provided by the power supply.

The battery is connected to a PowerBoost power supply that can be Li-

Ion batteries and provide protection for low voltage batteries.

The power supply also provides a way to turn the candle on or off by switching to ground EN connection.

The Clapper PCB includes Solid State Relays (LCB710)

And single chip (ATTiny85)

Process the signal of the sound module and control the power supply of the candle PCB.

ATTiny85 is programmed to listen to two loud sounds at the same time and turn the relay on or off.

Unfortunately, this configuration cannot distinguish clapping from any other loud sound, so the circuit will activate if any two loud sounds are heard at the same time.

I installed a DIP-

8 outlets on the Clapper PCB for easy installation or removal of attiny85.

All other components can be welded to the circuit board.

Connect pins 1 and 2 of J1 for normal operation.

Second, connection &-

Pin and &-of Cl Board PCB &-

Candle PCB.

Connect the 5 v and GND of the PowerBoost power supply &-

Connection of \"clapper plate of\" pressurized water reactor.

Connect the mini Toggle Switch SPDT to the \"CLAPPER\" connection.

Connect the lever of the switch to C and the other two as needed.

Finally, connect the VCC and GND of the sound module &-

Output of \"snd mod\" and output connection of Clapper PCB.

Attached is the Gerber file I created with KiCad for ordering two printed circuit boards.

I recently ordered 10 candle flame pcb for $5.

As it happens, I ordered twice the motherboard for half the price of my original 2016 order.

Adafruit offers a tutorial on using LED charity matrix and drivers in animated flame pendants.

I used the same sketch on Arduino Pro Mini but changed the data.

The flame I made.

This tutorial provides everything you need to get started with LED Charlies.

ATTiny85 used the sketch I found on Henry\'s bench

Arduino sound detection sensor: tutorial and user manual.

This page will guide you through the configuration and tuning of the sound sensor module and Arduino. My sketch (

ClapperCandle_V2. ino)

Because ATTiny is almost the same as his example.

After the Pcb assembly is completed, it can now be installed on the acrylic base.

As mentioned earlier, drilling is recommended before bonding.

If you are building the Clapper version, the previously cut rectangular spacers are located on the side of the sound module installation position.

This can be seen in the photo above.

The Clapper PCB is installed below the sound module and on the same side.

Connect the PowerBoost 500 power supply to the battery and the main power switch, and if the Clapper PCB is not used, connect the 5 VDC and GND directly to the \"pwr in\" connection of the candle PCB.

Otherwise, connect the output voltage of the power supply &-

PCB.

Connect the SPDT toggle switch to the \"CLAPPER\" connection as indicated earlier and connect the sound module to the \"snd mod\" as indicated earlier \".

Respective connections (+ -TRG)

The PCB of the Cl board is connected to the candle PCB.

The TRG connection is not connected to anything.

Check your line against the schematic, when you are ready to install the battery and turn it on.

Resin candles require a micro USB cable to be connected to the holes in the power supply.

So I installed these on my CNC and cut a hole at the right distance from the bottom. ENJOY!

Custom message