Item | Process Capability | Typical value |

Layers | ≤20 | 14 |

Size | ≤247*446mm | 87.6×154.8mm |

Total Thickness | ≤3.0mm | 1.6mm |

Cavity Size | 3×10 - 100×150mm | 53.7~81.3mm |

Resin flow | -0.25mm~0.5mm | 0.2 |

Cushion pad thk. | 0.4mm≤H≤1.0mm | 0.4mm |

Cavity depth | ≥0.6mm | 0.6mm |

Remaining thk. | ≥0.5mm | 1.0mm |

PTH to cavity distance | ≥0.5mm | 0.5mm |

Base Material | LF compatible | S1000-2 |

Surface treatment | ENIG,I-Sn, OSP | OSP+GF |

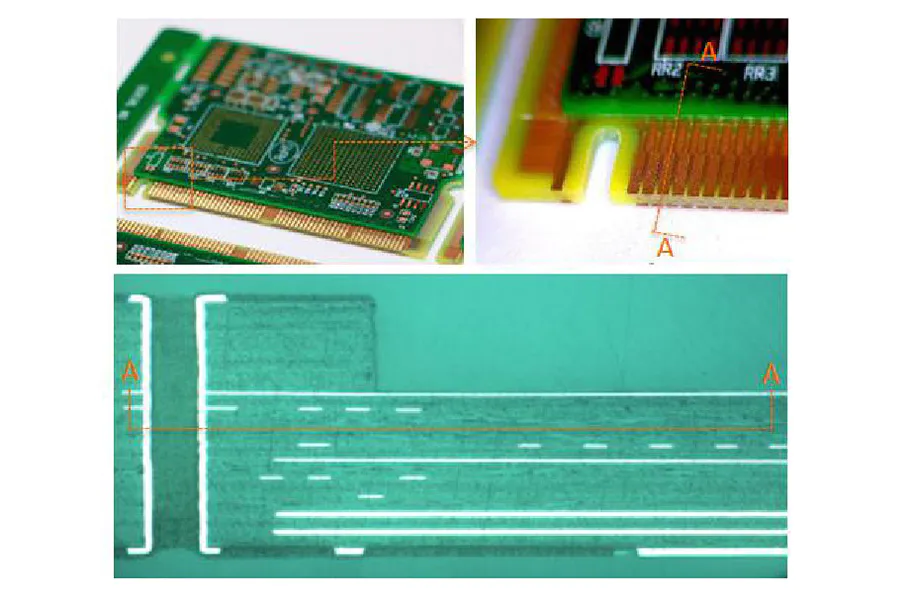

With the development of PCB to high density, the number of layers is getting higher and higher. But for the gold finger/bonding finger board, the thickness of the gold finger board is required to be 1.6mm-1.8mm. If it is more than 1.8mm, it will not meet the assembly requirements. Therefore, if the number of layers is more than 14 and impedance control is needed, the thickness of PCB is difficult to be controlled below 1.8mm. At this time, if the gold finger technology is still needed, the number of layers can only be reduced or sacrificial impedance matching to meet the requirements.

In addition, printed circuit board (PCB) board with golden finger is generally designed within the surface area of the circuit board. The gold finger provided with plug-in function shall match the size of plug-in interface, and the thickness of gold finger circuit board shall be consistent with the opening height of plug-in interface. When the opening height of plug-in interface is fixed, the thickness of circuit board where the gold finger is located also fixed.

When the gold finger circuit board needs to increase the board thickness to achieve multi-functional requirements, the matching plug-in interface equipment needs to be completely transformed, which is a waste of resources and costs. The cavity gold finger design solves this problem very well. Through the way of inner layer gold finger plated, sticking high-temperature tape, adding pp gasket and control-deep milling after lamination, the gold finger can be led out from the inner layer to achieve functional requirements.