What is Aluminium backed PCB(or metal backed pcb)?

Bonding metal heat sinks to PCBs is a common method for electronic cooling solutions. Depending on the electrical requirements, the bonding material used can be either a dielectric film or a conductive film.

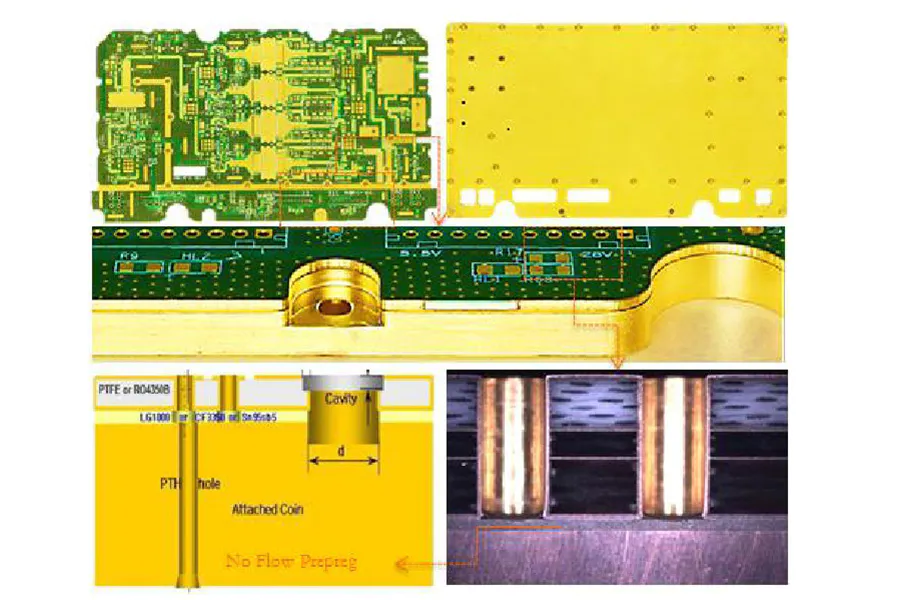

Bonding PCBs to metal via dielectric materials (e.g. FR-4 prepreg) can be used for a variety of applications. Since metal parts are usually machined and surface treated before bonding, the prepregs used are mostly non-flow or low-flow types to avoid excessive resin leakage into the module cavity. For RF power amplifiers, metal heat sinks need to be grounded through the PCB, and conductive films (e.g. ablefilm cf-3350) are widely used.

As one of the world's leading mobile base station power amplifier PCB manufacturers, Rocket PCB has a high capability in building metal press-fit PCBs. The laminate/dielectric material suppliers we use include: isolata, nelco, Rogers & Taconic. We produce metal core PCBs in aluminum, copper and brass composites.

Below are the process bonding requirements as well as the flow chart:

Typical Index | Process Capability | Typical value |

Layers | ≤6L | 2L |

material | RO4350B、RF35、RF35A2 | RF35 |

Metal base | Copper, Aluminum | copper |

Metal thk. | ≤4.5mm | 3.5mm |

Bonding Material | LG1000、CF3350 | LG1000 |

Metal Size | MAX:180mm*280mm | 120mm*230mm |

registration | ±4mil (metal to PCB) | ±4mil (metal to PCB) |

Resin flow at cavity | ±0.2mm | ±0.2mm |

Surface treatment | ENIG | ENIG |

Bonding type | Full /Partial bonding, | Full sheet bonding |

Application | Communication, PA, RF | |