Auto PCB circuit boards to compensate for the defects

by:Rocket PCB

2020-06-25

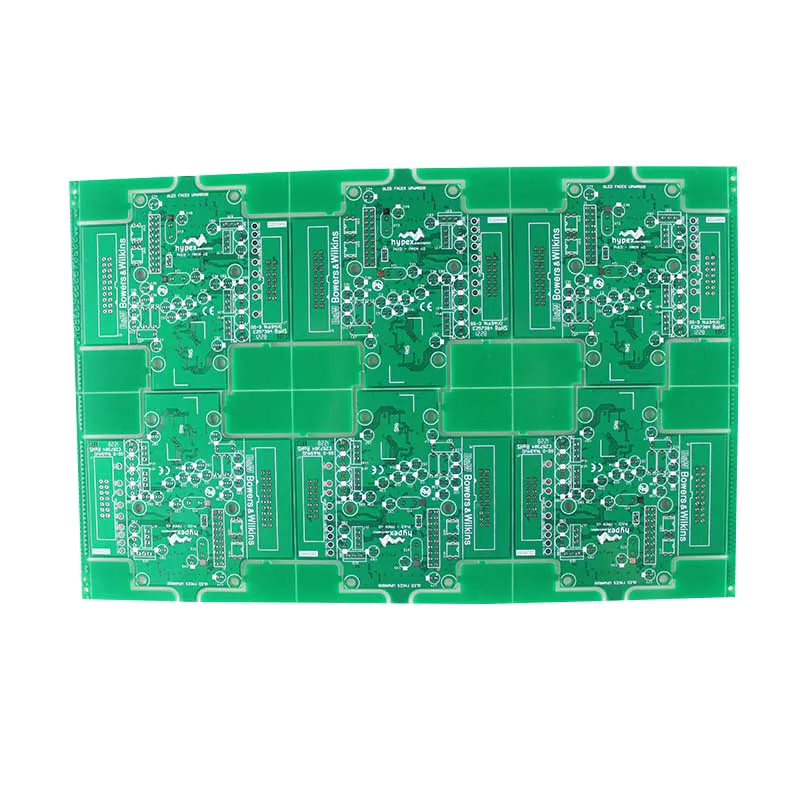

Automotive electronics market is the third largest PCB after computer, communications applications.

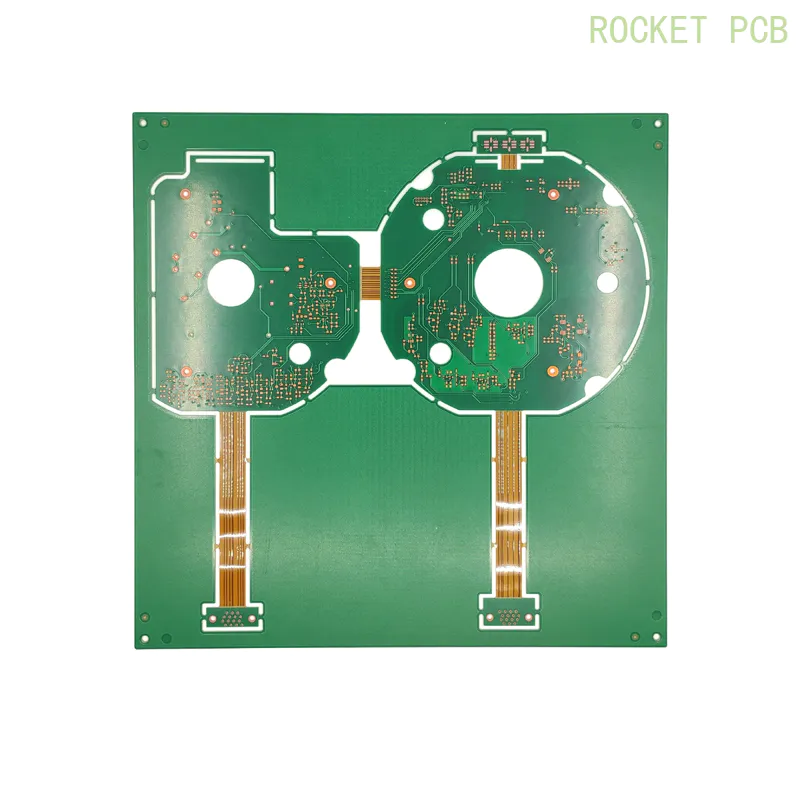

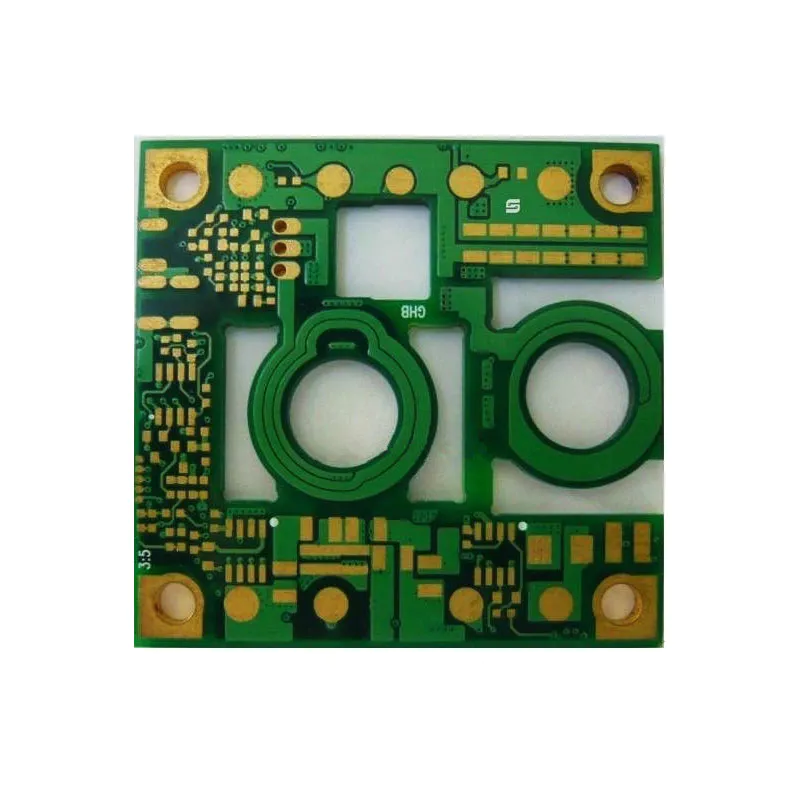

With cars from the traditional mechanical products, evolution, gradually developed into intelligent, informatization, mechanical and electrical integration of high-tech products, electronic technology was widely applied in the car, whether the engine system, or the chassis system, security system, information system, the interior environment system are invariably adopted electronic products.

Auto market clearly has become the consumer electronics market and a bright spot, the development of automotive electronics, naturally lead to the development of the auto PCB.

In today's PCB key application object, automotive PCB would occupy the important position.

But because of the special working environment, security, automotive and large current requirements, such as its reliability of PCB circuit boards, environmental adaptability, high demand of PCB technology type also widely, for PCB enterprises, this is a challenge.

And to develop car PCB market makers, need to do more for the understanding and analysis of the new market.

Cars with PCB with particular emphasis on high reliability and low DPPM, so, whether our enterprise in high reliability, manufacturing technology and experience accumulated?

Whether agree with the product development direction in the future?

On the process control, if you can do well according to the requirements of TS16949?

Already have low DPPM?

These have to do careful evaluation, see the tempting cake and blindly into the light, will bring harm to the enterprise itself.

14 below provide a representative part of PCB enterprise specializing in the production of automotive PCB in the process of testing some special practice provided to those customers PCB with reference: 1, the second test of PCB production enterprises adopt 'secondary test method' to improve the plate to find the first high voltage breakdown rate.

Part 2, comparative tests using two different customers different batch PCB brand model, comparison test, and follow the corresponding batch of PPm, to understand the status of the two kinds of testing machine performance, so as to choose a better test machine to test the performance of the car with PCB.

3, improve test parameters selection of higher test to strict investigation this kind of PCB.

Because, if you choose a higher voltage and threshold, increase the high pressure read number of leakage, can improve the detection rate of defect PCB board.

Such as suzhou a large taiwanese-owned PCB enterprise USES the 300 v, 30 m, 20 euro with PCB test car.

4, regular check testing machine parameters testing machine after long-term operation, the internal resistance and relevant test parameters will have deviation.

So need to regular calibration machine parameters, to ensure the accuracy of the test parameters.

PCB test equipment in quite a number of large enterprises were six months or a year for the machine maintenance, calibration internal performance parameters.

The pursuit of 'zero defect' automotive PCB have been the direction of the efforts for the PCB circuit boards, but to the limitation of process equipment, raw materials, PCB enterprise of the world still continue to explore the method of reduce PPm.

5 spending more and more test system, the bad board PCB manufacturer in plate test machine installed 'good plate marking system' and 'bad board mistake proofing box' to effectively avoid artificial leak.

Good plate marking system for testing machine to test PASS board are identified, which can effectively prevent the test plate or bad flow into the hands of the customer.

Bad board mistake proofing box is in the process of test, test PASS board, testing the system output the signal open the box;

Conversely, test out the bad board, box shut down, let the operator positioned properly tested circuit board.

6, to set up the current PPm (PPm quality system

Partspermillion, hundred million defect rate)

Quality system is widely used on the PCB manufacturer.

In my company customers to Singapore HitachiChemICal its application and the results are the most worth using for reference.

In the factory has more than 20 people responsible for the quality of the PCB and PCB quality anomaly online return of statistical analysis.

Production process using SPC statistical analysis method, each piece of bad board and classify the defect board each returned after statistical analysis, and combining the micro section analysis tools such as bad and defect board in which production process.

According to the statistical data as a result, have the destination to solve the problems in the process.

pcb making service pcb manufacturing services, as the name suggests, find extensive use in pcb manufacturing services institutions. Since pcb manufacturing services has become much dependent on technology in today's world, there is wide use of such pcb making service.

If you would like a great tip on where you can get pcb making service pcb manufacturing services for a great price, check out Rocket PCB . Rocket PCB Solution Ltd. is committed to serving globally recognized . Quality is guaranteed here. Make your wise decision.

By investing in an ethical supply chain, Rocket PCB Solution Ltd. position ourselves to engage with a driven, engaged customer base.

Rocket PCB Solution Ltd. offers not only the high-quality product but also the finest service, gives the customer with an expressive using experience.

Before investing in a pcb manufacturing services pcb making service, it can benefit to have an understanding of the different types of and the most effective strategies to pcb manufacturing services. Go to Rocket PCB for more tips.

pcb making service pcb manufacturing services, as the name suggests, find extensive use in pcb manufacturing services institutions. Since pcb manufacturing services has become much dependent on technology in today's world, there is wide use of such pcb making service.

If you would like a great tip on where you can get pcb making service pcb manufacturing services for a great price, check out Rocket PCB . Rocket PCB Solution Ltd. is committed to serving globally recognized . Quality is guaranteed here. Make your wise decision.

By investing in an ethical supply chain, Rocket PCB Solution Ltd. position ourselves to engage with a driven, engaged customer base.

Rocket PCB Solution Ltd. offers not only the high-quality product but also the finest service, gives the customer with an expressive using experience.

Before investing in a pcb manufacturing services pcb making service, it can benefit to have an understanding of the different types of and the most effective strategies to pcb manufacturing services. Go to Rocket PCB for more tips.

Custom message