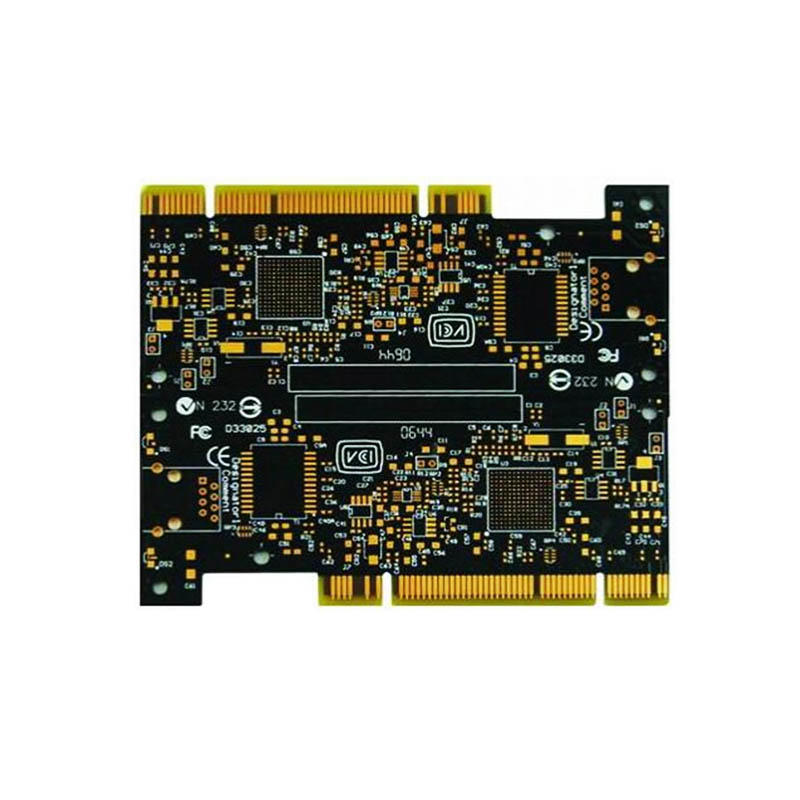

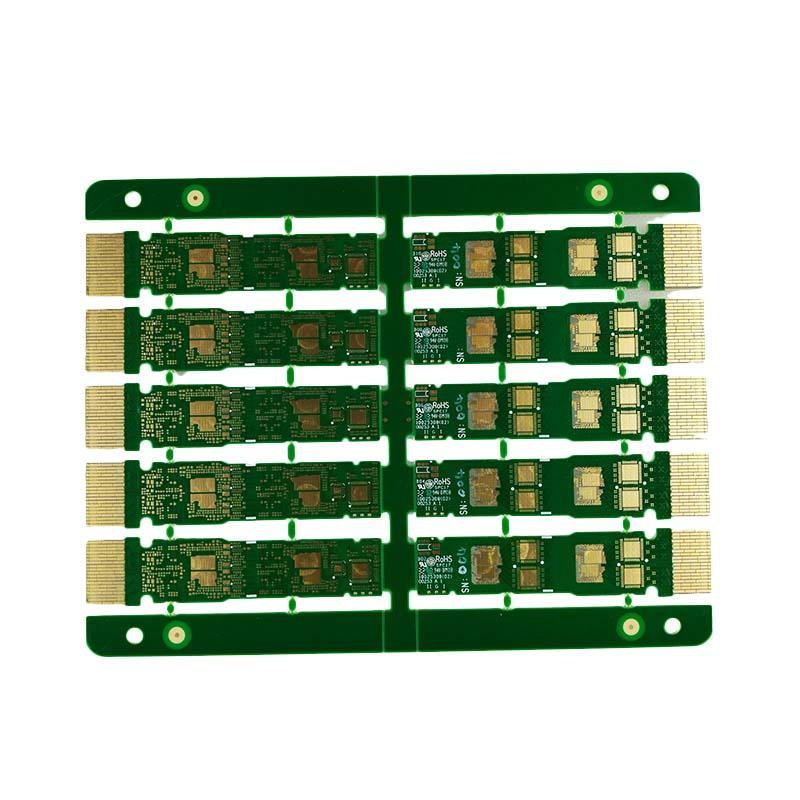

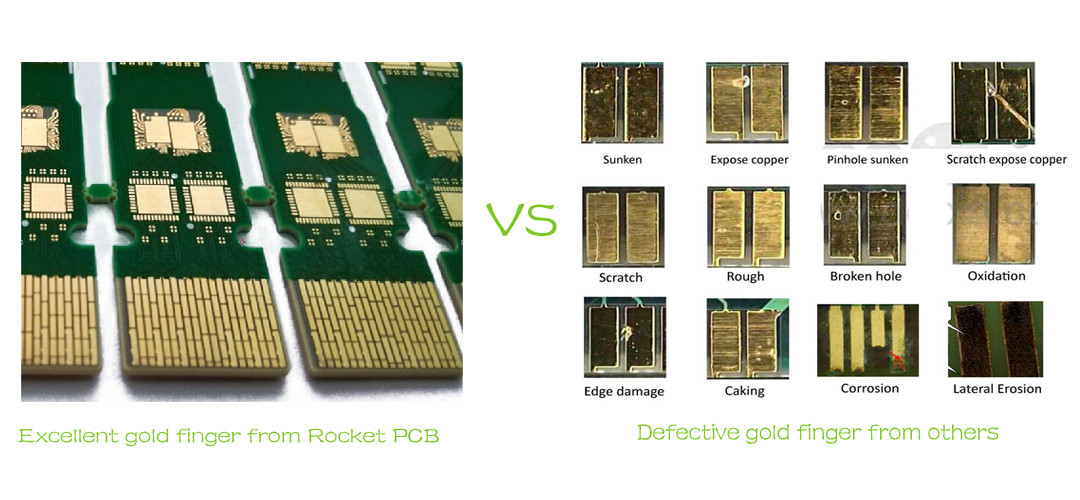

Rocket PCB provides gold finger PCB,

long-short gold finger PCB, staged gold finger PCB fabrication. Gold

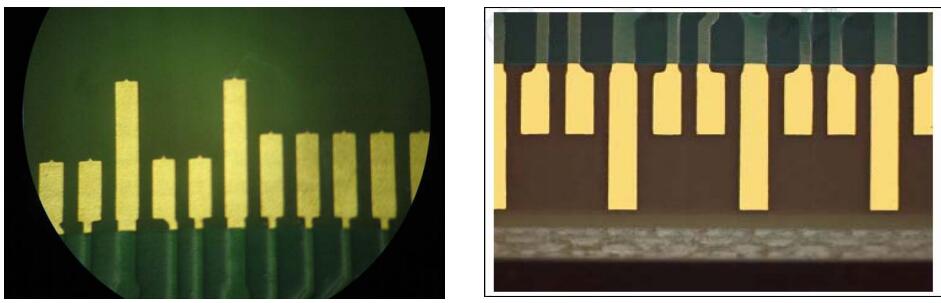

finger PCB put forward higher requirements for the manufacturing

technology. If you don't have enough experience, it is easy to cause bad

problems such as blackening, whitening, contamination,lateral erosion,

scratch and other problems.

Rocket PCB has extensive experience in this field and have accumulated many years

of processing experience. Through process optimization, improve film

alignment, liquid concentration control, plating parameters and other

links of optimization. Our gold finger quality fully meet customer

requirements, won customer appreciation.

Generally speaking, the golden finger means that these fingers are plated with 5-30u”hard gold. Hard gold has better wear resistance, and can be guaranteed 20,000 times insertion without affecting the quality, it must be more than 5u”thick. However, the processing technology of hard gold is relatively complex, and the high thickness of gold consumes more gold salt, which directly results in high cost. In fact, many PCBs do not need frequent insertion, do not need to do thick gold, or even do not do hard gold, directly do immersion gold replacement (soft gold, gold thickness is generally 1-3 u”). It can effectively reduce the purchase price of PCB.

Some common applications of golden fingers are:

◪ Provide interconnection points for transmitting network data.

◪ Where a sub-board or dedicated adapter is attached

◪ Connect external components to the prototype PCB

ENIG:

ENIG is more cost-effective and easier to solder than the electric gold

plating. But its soft and thin (usually 2-5u ")composition makes the

ENIG unsuitable for achieving the abrasion effect caused by the circuit

board insertion and removal.

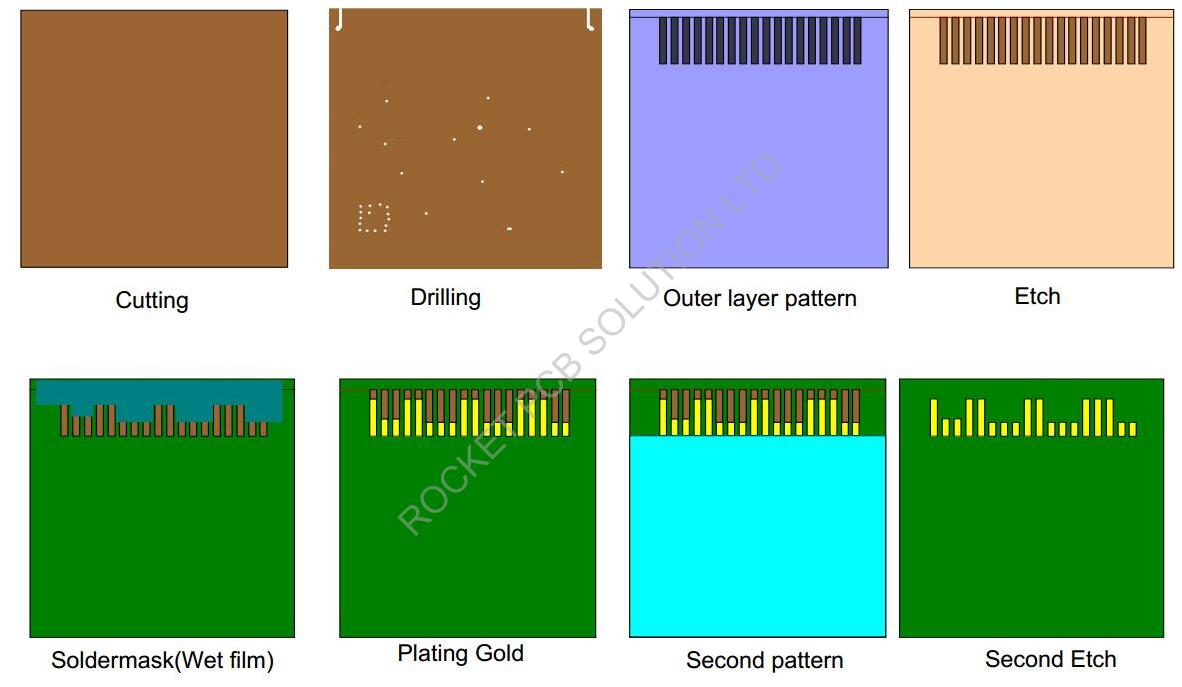

Electroplated Hard gold: This

gold is solid (hard) and thick (usually 30u "), so it is more ideal for

achieving the abrasive effects caused by constant PCB usage.

There

are many meticulous steps involved in the process of plating gold

fingers. To ensure that all of these fingers and slots fit, each PCB

must pass a series of inspections and defect tests.

Standard gold finger:Gold fingers are of equal length.

Staged gold finger PCB :The etching pattern of the golden finger position needs to be realized by multiple film pasting, exposure and solder masking. The position and pattern need to be strictly and accurately controlled.

Long-short gold finger PCB:Its process is similar to the staged gold finger, which requires multiple exposure and electroplating to obtain the graphics of the long- short gold finger and requires the following design rules: plated holes, SMD and pads should not be placed within 1.0 millimeters of the gold finger; plated pads cannot exceed 40 millimeters in length.

As more and more technologies rely on gold fingers, it is vital that we have them plated and tested to meet the highest standard and to ensure the highest performance. Rocket PCB provides the PCB with the highest quality for customers from different industries with our extensive experience.

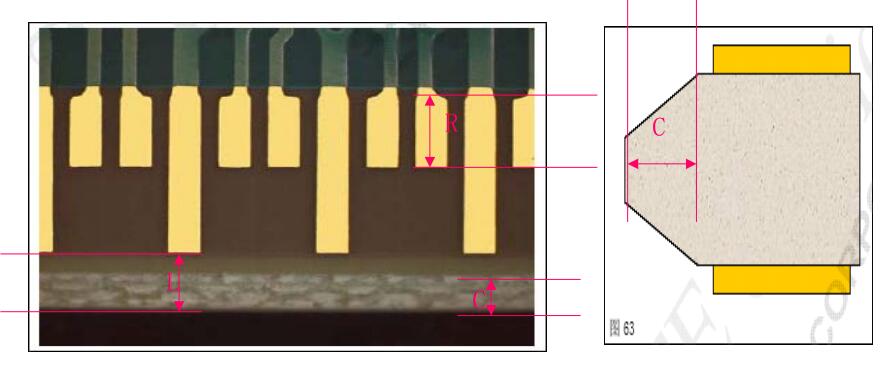

Key dimensions control

◪ 24 hour real-time technical support

◪ Quick turnaround with 24 hours and instant quote

◪ Effective and flexible PCB engineering solutions save your cost

◪ State-of-the-art PCB including rigid, FPC, rigid-flex, metal base, RF/microwave, hybrid, HDI, embedded, LED, backplane, ceramic substrate, IC substrate

◪ Strong partnerships with different reputed material suppliers such as Rogers, Arlon, Nelco and Taconic can realize a fast service to a wide range of PCB applications

◪ Superb quality are guaranteed under the ISO9001, ISO14001, TS16949, OHSAS18001, ISO/IEC27001 system, insist on adopting 5S methods, Lean Six Sigma quality systems

◪ Complete service from free DFM, traceable manufacturing to complete after-sales service

◪ On time delivery more than 99%

Security Industry

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink