AOI inspection problems in SMT processing is introduced

by:Rocket PCB

2020-07-18

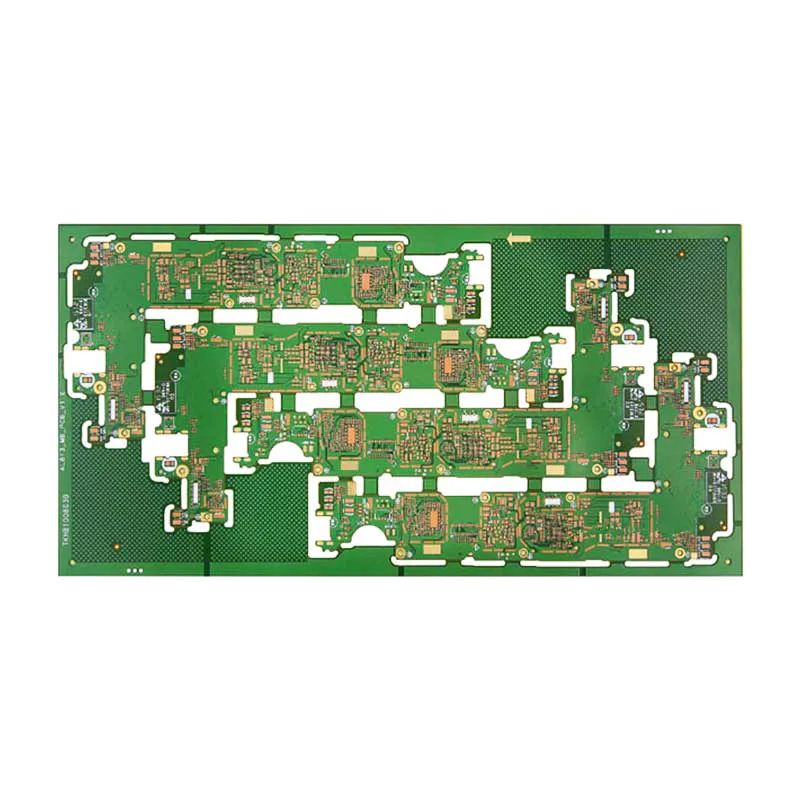

In SMT processing production, AOI detection is handled through image acquisition and analysis results, higher efficiency than artificial visual inspection.

Due to the relevant technology of the image analysis processing, after all, haven't reached the human level, so there are some AOI in SMT processing of misjudgment, false negative phenomenon, this is because after completion of AOI in SMT placement tests will exist several problems: 1, screen Yang, shield, shielding point detection problem.

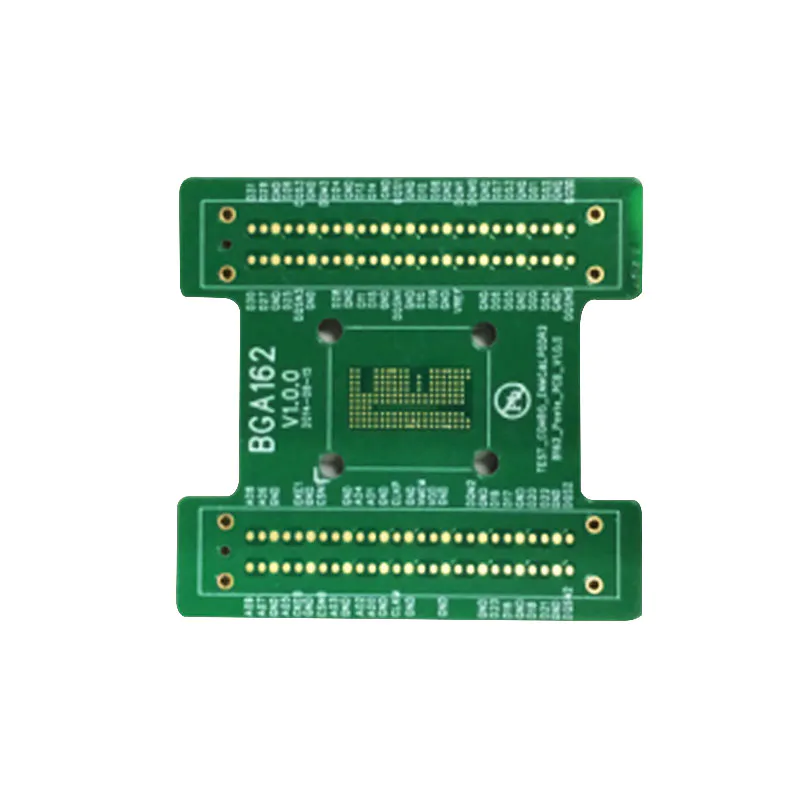

2, not for BGA, FC invisible solder joint inversion components such as testing.

3, most of the AOI in the understanding of the virtual welding, cause false negatives shuffle.

4, character processing in a different way, polarity judgment accuracy caused by differences in the school.

5, capacitance value size and color the same and different specifications, easy to cause false negatives.

More than six, SMT tin, tin, offset, skew less standard defines different technological requirements, easy to cause misjudgment.

7, some points rate lower AOI cannot do OCR character recognition detection.

8, most AOI slower product testing, the few AOUI faster scanning methods, but wrongly sentenced to pan rate is higher.

9, most of the AOI programming complex, cumbersome and adjust the time is long, not suitable for scientific research units, small OEM factory, small batch production unit of many specifications.

Patch to solve above problems found in PCB PCB, SMT processing plants in addition to increasing product checking personnel also need to form a complete set of auxiliary equipment, AOI not only online AOI, also have off-line AOI equipment, thus in the quality control links, we need to very seriously.

The above in a timely manner after completion of AOI in SMT processing will exist problems in the testing, in order to improve the situation, not due to increasing product checking personnel also auxiliary equipment (

Include AOI online and off-line AOI equipment)

Hold good quality control links, to ensure the quality of the products.

Good product casting brand, dongguan Rocket PCB manufacturers look forward to cooperate with you!

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multilayer circuit board production, advanced HDI board, circuit boards, blind hole buried thick copper PCB proofing and small batch, high frequency circuit boards and PCB board production.

Which contains in the high-end electronic products SMT/PCBA processing such as core business.

Under the same cost we faster delivery, under the same delivery speed our costs are lower.

At present, the Rocket PCB circuit has PCB circuit board production base and technology research and development base, in the domestic several major electronic product design center layout service center, has for more than 2000 customers worldwide rapid electronic manufacturing services.

The average consumer is always looking for ways to save money while finding out solutions, is designed for killing two birds with one stone, providing a perfect solution to pcb making service problems.

Rocket PCB Solution Ltd.’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

Rocket PCB Solution Ltd.'s pcb making service are sturdy, easy to operate, friendly work machines that deliver high-quality pcb manufacturing services for pcb manufacturing services purposes.

pcb making service can be applied in different ways as pcb manufacturing services.

We are making pcb making service available to you at a very low price.

The average consumer is always looking for ways to save money while finding out solutions, is designed for killing two birds with one stone, providing a perfect solution to pcb making service problems.

Rocket PCB Solution Ltd.’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

Rocket PCB Solution Ltd.'s pcb making service are sturdy, easy to operate, friendly work machines that deliver high-quality pcb manufacturing services for pcb manufacturing services purposes.

pcb making service can be applied in different ways as pcb manufacturing services.

We are making pcb making service available to you at a very low price.

Custom message